Method for removing arsenic and recycling tungsten from tungsten smelting wastewater

A recovery method and technology for wastewater, applied in the fields of metallurgical wastewater treatment, chemical instruments and methods, water pollutants, etc., can solve the problems of tungsten leakage, reducing the metal recovery rate of APT production, and lack of applicable technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

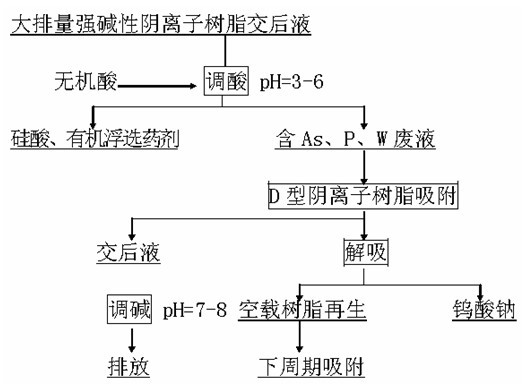

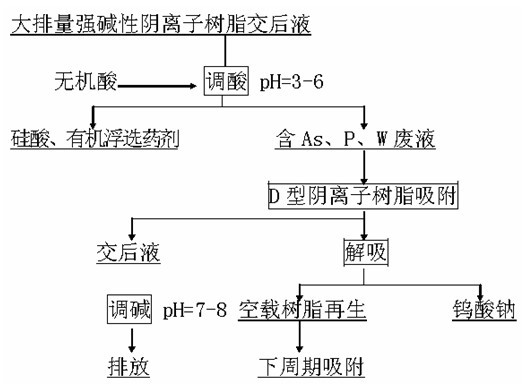

[0011] Such as figure 1 As shown, the steps for the removal of arsenic in tungsten smelting wastewater and the recovery of tungsten are as follows: ① Add hydrochloric acid to the waste liquid after the strong alkaline anion resin exchange of sodium tungstate solution to adjust it to a weakly acidic pH=3-6, At the same time, a small amount of polyacrylamide is added to flocculate a large amount of flotation reagents and silicic acid in the solution into fine solid particles, and then pass through the environmentally friendly PE sintered tubular filter to completely remove their interference on the D-type anion resin exchange process. ; ②The weakly acidic waste water after filtering out the suspended solids is injected into the exchange column equipped with D-type anion resin, and the arsenic and phosphorus in the waste water are all absorbed by the D-type anion resin; ③The resin is desorbed with caustic soda solution, and the desorption liquid is Concentrate so that 90% of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com