X80 pipeline steel submerged arc welding wire

A technology of pipeline steel and welding wire, applied in arc welding equipment, welding medium, welding equipment, etc., can solve the problem that X80 steel is not suitable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

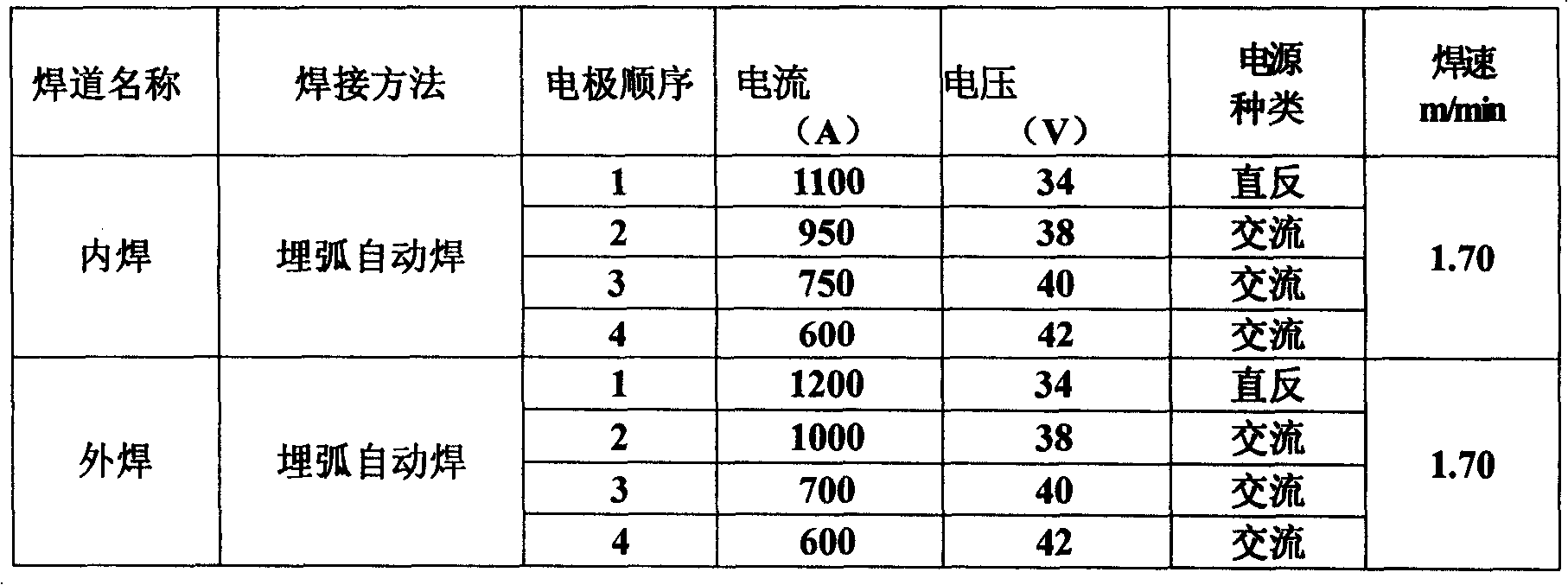

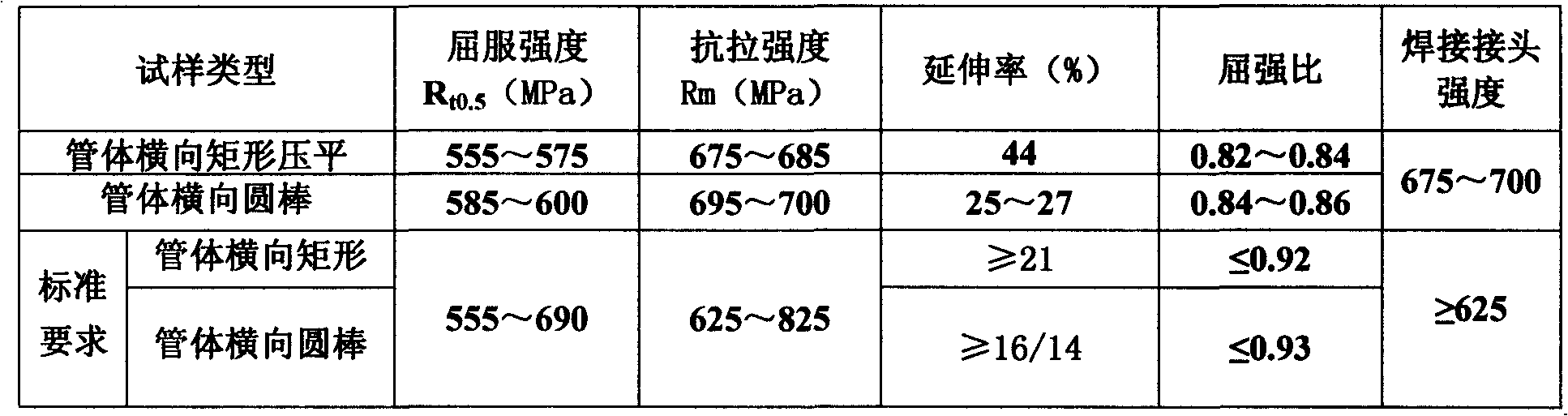

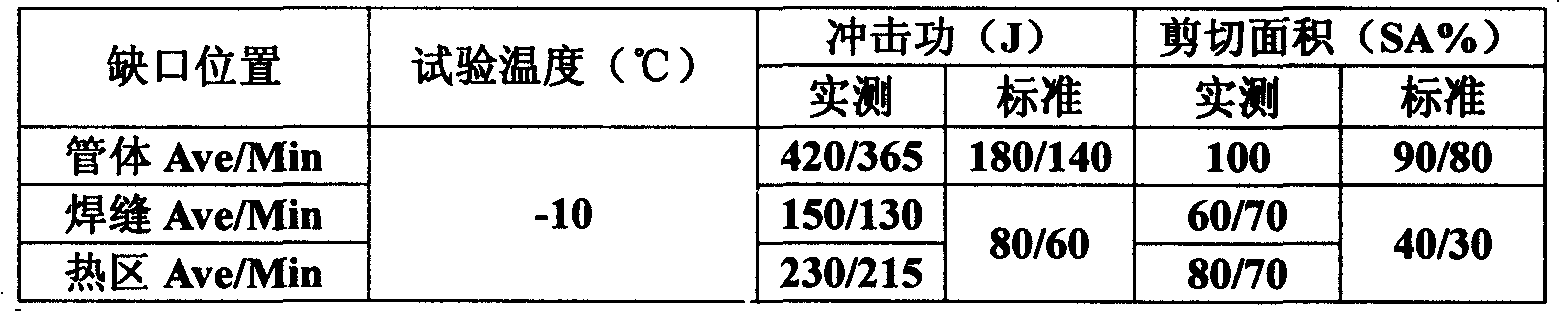

[0025] The chemical composition of the welding wire in this embodiment is shown in Table 1. The actual chemical composition and standard composition of the X80 and 22mm steel plates used for welding X80 and Φ1219×22mm LSAW pipes are shown in Table 2, the composition of the flux is shown in Table 3, and the welding process parameters are shown in Table 4. Table 5 shows the analysis results of the chemical composition of the weld, and Tables 6, 7, and 8 show the performance test results of the steel pipes. It can be seen from the table that the weld seam and heat-affected zone quality of X80 high-strength and high-toughness Φ1219×22mm longitudinal submerged arc welded pipe can meet the technical requirements of high strength, high toughness, bending and low hardness of welded steel pipe for oil and gas transportation. In particular, it can meet the technical standard requirements for submerged arc welded pipes used in the natural gas pipeline project of the Second West-East Gas ...

Embodiment 2

[0043] The chemical composition of the welding wire of this embodiment is shown in Table 9. The actual chemical composition and standard composition of the X80 steel plate used for welding X80 and Φ1219×26.4mm LSAW pipes are shown in Table 10, the composition of the flux is shown in Table 11, and the welding process parameters are shown in Table 12. Table 13 shows the analysis results of the chemical composition of the weld, and Tables 14, 15, and 16 show the performance test results of the steel pipes. It can be seen from the table that the weld seam and heat-affected zone quality of X80 high-strength and high-toughness Φ1219×26.4mm LSAW pipe can meet the technical requirements for high strength, high toughness, bending and low hardness of welded steel pipe for oil and gas transportation. In particular, it can meet the technical standard requirements for submerged arc welded pipes used in the natural gas pipeline project of the Second West-East Gas Pipeline Project, which fil...

Embodiment 3

[0061] The chemical composition of the welding wire of this embodiment is shown in Table 17. The actual chemical composition and standard composition of the X80 steel plate used for welding X80 and Φ1219×33mm LSAW pipes are shown in Table 18, the composition of the flux is shown in Table 19, and the welding process parameters are shown in Table 20. Table 21 shows the chemical composition analysis results of the weld, and Tables 22, 23, and 24 show the performance test results of the steel pipes. It can be seen from the table that the weld seam and heat-affected zone quality of X80 high-strength and high-toughness Φ1219×33mm LSAW pipe can meet the technical requirements for high strength, high toughness, bending and low hardness of welded steel pipe for oil and gas transportation. In particular, it can meet the technical standard requirements for submerged arc welded pipes used in the natural gas pipeline project of the Second West-East Gas Pipeline Project, which fills the gap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com