Pure aluminium iron compound deoxidant and its production process

A composite deoxidizer and production process technology, applied in the field of metallurgy, can solve the problems of reduced deoxidation effect, small reaction interface, waste, etc., and achieve the effect of reducing deoxidation cost and improving yield

Inactive Publication Date: 2003-02-05

HENAN XIBAO METALLURGICAL MATERIALS GROUP

View PDF0 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] For a long time, in the smelting process of iron and steel enterprises, the composition adjustment and deoxidation are usually carried out by the alloy formed by metal aluminum or aluminum-iron remelting. Although these deoxidizers can improve the deoxidation effect, they are not ideal, and there are some difficult problems to solve , the main disadvantage of the metal aluminum deoxidizer is that it reacts violently during the deoxidation process, causing part of the aluminum to be burned, and cannot participate in the molten steel reaction and is wasted in vain. Small, limited to the upper part or surface of molten steel, so that the deoxidation effect is significantly reduced, and the yield of aluminum is less

Although the aluminum-iron alloy deoxidizer produced by remelting increases the specific gravity, the alloy after melting obviously changes the properties of the original metal aluminum, making its melting point rise, and the melting speed is too slow, which is not conducive to melting in molten steel and affects the quality of aluminum. Yield, reduce deoxidation effect

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0031] Embodiment 1 (percentage by weight)

[0032] Aluminum 30% Iron 70%

Embodiment 2

[0033] Embodiment 2 (percentage by weight)

[0034] Aluminum 40% Iron 60%

Embodiment 3

[0035] Embodiment 3 (percentage by weight)

[0036] Aluminum 50% Iron 50%

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

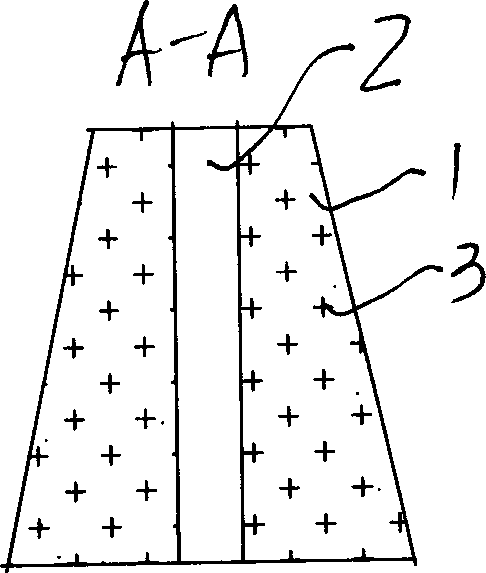

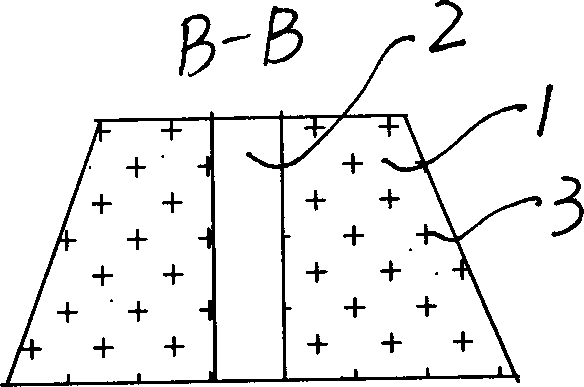

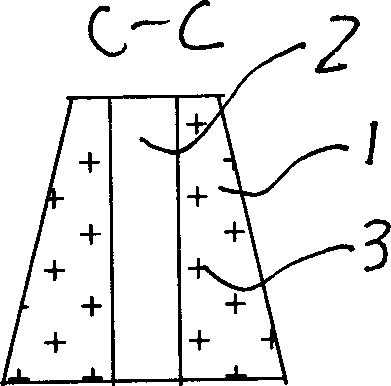

The present invention relates to a pure aluminium iron composite deoxidant and its production process. It includes 30-70% of aluminium and 70-30% of iron, and its production process includes the following steps: (1). adopting aluminium-melting furnace to melt high-purity aluminium; (2) pouring the molten aluminium into the mould with frustum form, trapezoidal tower form or triangular tower form and forming, continuously heating the mould and making the molten aluminium be in liquid state; (3). quick adding preheated pure iron granules or iron chipings; and (4) lightly and slowly vibrating mould and making the iron granules or iron chipings uniformly dispersed in molten aluminium, solidifying to form aluminium-iron composition whose specific weight can be up to 2.8 g / cu.cm-6.8 g / cu.cm.

Description

Technical field: [0001] The invention relates to the field of metallurgy, in particular to a pure aluminum-iron composite deoxidizer, and also relates to a production process of the pure aluminum-iron composite deoxidizer. Background technique: [0002] For a long time, in the smelting process of iron and steel enterprises, the composition adjustment and deoxidation are usually carried out by the alloy formed by metal aluminum or aluminum-iron remelting. Although these deoxidizers can improve the deoxidation effect, they are not ideal, and there are some difficult problems to solve , the main disadvantage of the metal aluminum deoxidizer is that it reacts violently during the deoxidation process, causing part of the aluminum to be burned, and cannot participate in the molten steel reaction and is wasted in vain. Small, limited to the upper part or surface of molten steel, so that the deoxidation effect is significantly reduced, and the yield of aluminum is less. Although th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C21C7/06

Inventor 李伟峰李书成

Owner HENAN XIBAO METALLURGICAL MATERIALS GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com