Production process of aluminium slag adjusting agent for LF refining furnace

A production process and refining furnace technology, applied in the field of aluminum slag adjustment agent, to achieve the effect of improving height, highlighting technological progress, and saving steelmaking costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] The production line is equipped with two AC-LF refining furnaces with a nominal capacity of 120 tons.

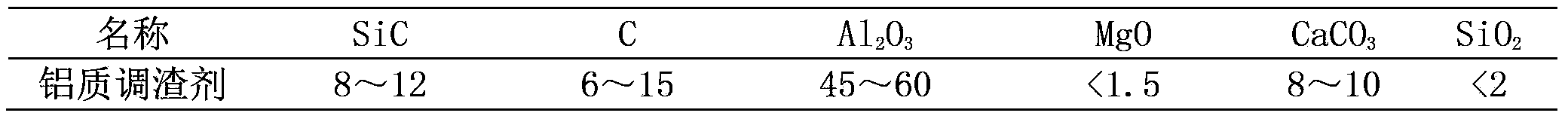

[0016] Process flow: discarded aluminum-silicon carbide-carbon bricks → crushing → grinding → adding limestone powder → pressing balls → power transmission for smelting.

[0017] 1) Waste refractories (Al 2 o 3 content of 71%) to the production plant, first sort out the industrial waste and iron-containing raw materials, wait for them to cool below 30 ℃, and use the outer dimensions of 1300×1400×1400mm produced by Shandong Jiuchang Heavy Industry Technology Co., Ltd. The PC0606 jaw crusher is used to crush the particles into 25mm particles, and then the particles are added to the 4R3216 Raymond Mill produced by Shanghai Jianshe Road and Bridge Machinery Equipment Co., Ltd., and processed into 2.9mm powders for use.

[0018] 2) Purchasing CaCO produced by Xinjiang Aiweiergou Harmony Mining Company 3 7 tons of limestone powder (particle size 0.9mm) with a content of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com