Chlorine component dry recovery process for co-processing chlorine-containing solid waste based on cement kiln

A technology of co-processing and dry recovery, applied in separation methods, furnace components, combustion methods, etc., can solve the problems of high secondary environmental pollution risks, many processing operation units, and high cost of separation of chlorine-containing components. The effect of small land area, simple process and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Below in conjunction with accompanying drawing, the present invention will be further explained:

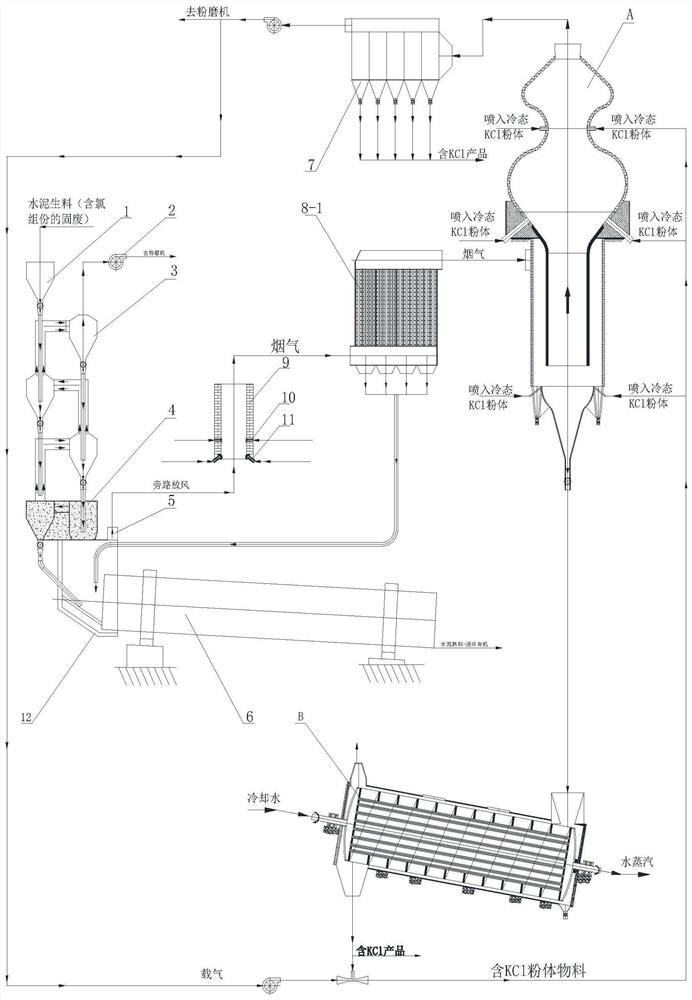

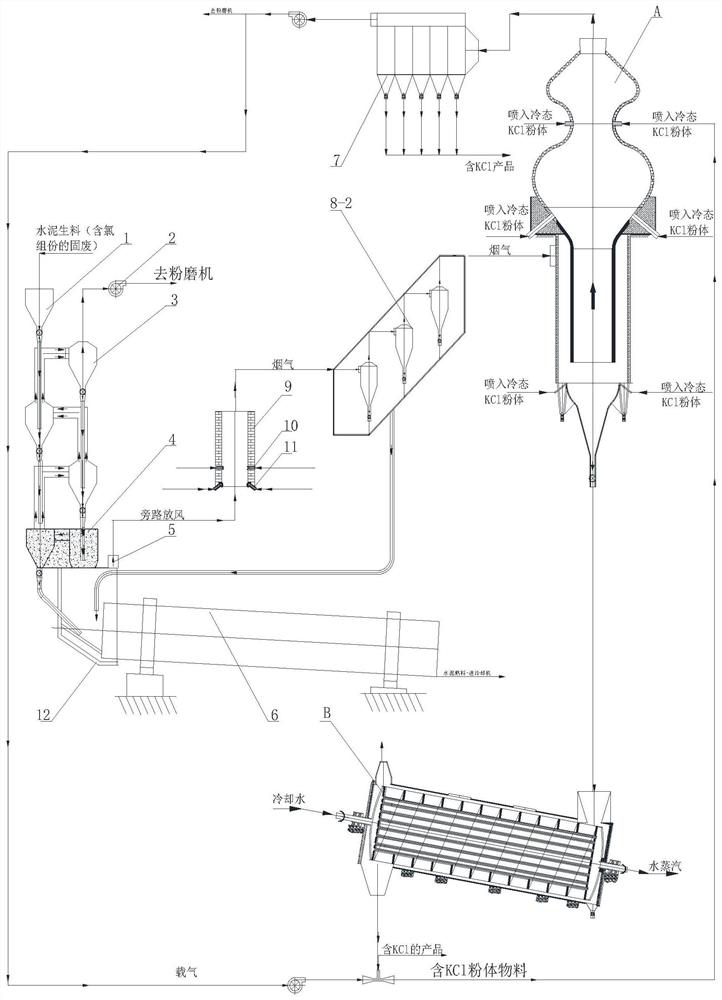

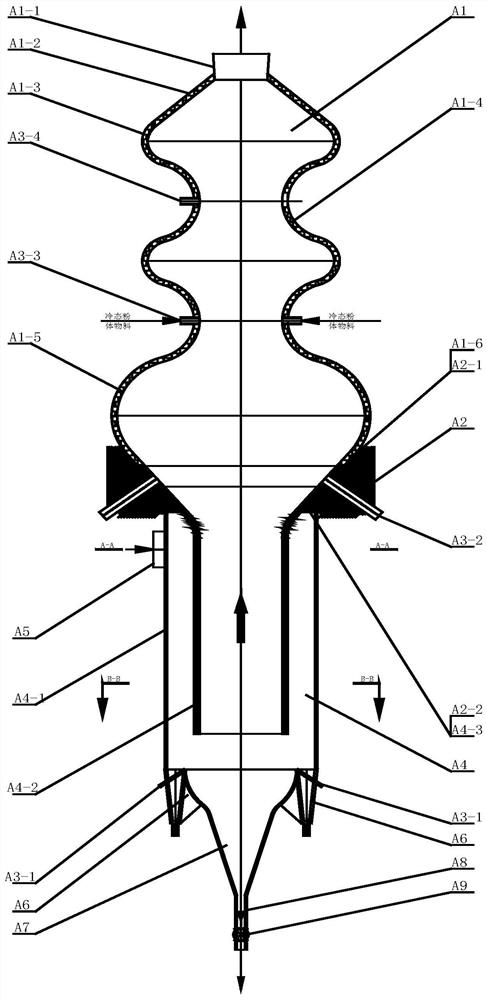

[0067] see figure 1 and figure 2 The system of the present invention is based on a cement kiln co-processing solid waste chlorine-containing component dry separation system, including a rotary kiln 6, the kiln head flue gas hood 12 of the rotary kiln 6 is provided with a bypass air inlet 5, and the bypass air inlet The tuyere 5 is connected with the flue gas inlet in the middle of the cooling tower (slag self-cleaning cooling tower A in this embodiment) through the dry dedusting device, and the middle part of the cooling tower is provided with a powder injection inlet; the powder at the bottom of the cooling tower The body outlet is connected to the heat exchanger (in this embodiment, the powder material spiral heat exchanger B), and the powder outlet of the heat exchanger is respectively connected to the outer discharge pipeline and the powder injection inlet of the coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com