Mechanical ventilation air cooling tower

An air cooling tower and mechanical technology, applied in the direction of fixed conduit components, heat exchanger types, lighting and heating equipment, etc., can solve the high temperature of circulating water outlet, which cannot meet the requirements of industrial production, mechanical ventilation air cooling tower Limitation of application range and other issues, to achieve the effect of not consuming water resources and enhancing heat exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

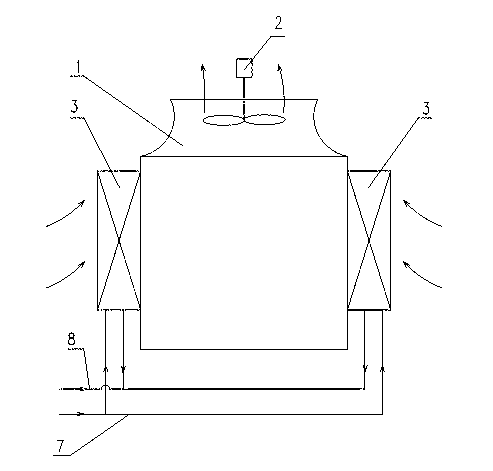

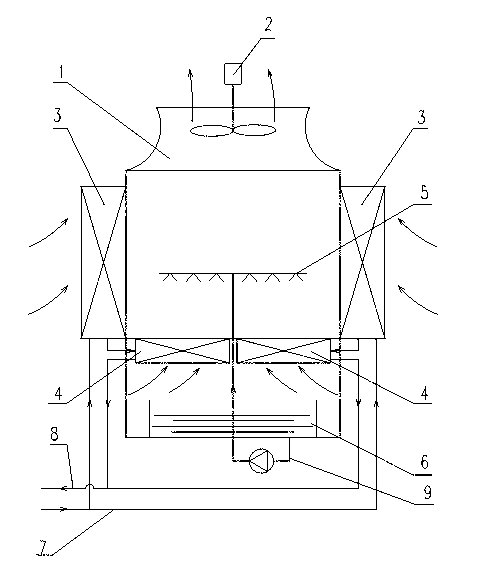

[0018] see figure 2 , figure 2 It is a schematic diagram of Embodiment 1 for implementing the present invention. Depend on figure 2 It can be seen that a mechanical ventilation air cooling tower of the present invention includes a tower body 1, a fan 2, a dry air-cooled radiator 3, an inlet pipe 7 and an outlet pipe 8, and the dry air-cooled radiator 3 is vertically arranged on the tower body 1 perimeter, with prior art mechanical draft air cooling towers (eg figure 1 As shown), the difference is that a wet air-cooling radiator 4 and a nozzle 5 are added inside the tower body 1, the wet air-cooling radiator 4 is arranged horizontally, and the nozzle 5 is arranged above the wet air-cooling radiator 4; below the wet air-cooling radiator 4 A water collection tank 6 is arranged, and the water collection tank 6 is connected to the nozzle 5 through a water spray device 9 . The wet air-cooling radiator 4 is arranged in series with the dry air-cooling radiator 3, and the indust...

Embodiment 2

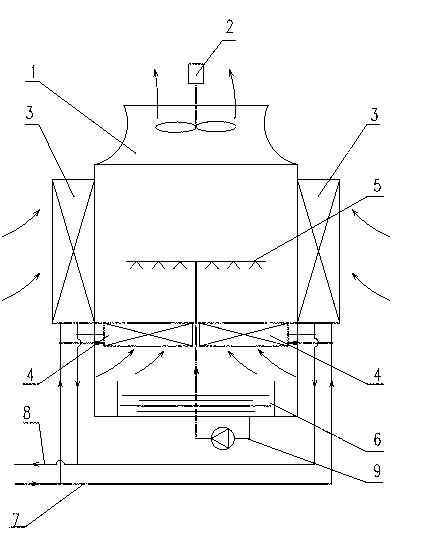

[0021] see image 3 , image 3 It is a schematic diagram of embodiment 2 of the present invention. The difference between Embodiment 2 and Embodiment 1 is that the wet air-cooling radiator 4 and the dry air-cooling radiator 3 are arranged in parallel, and the industrial circulating water enters the wet air-cooling radiator 4 and the dry air-cooling radiator 3 at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com