Heating and cooling system using swallet waste heat by industrial and mining enterprises

A technology for mine water inrush and industrial and mining enterprises, which is applied in the field of waste heat and waste heat resource utilization in coal systems, can solve the problems of high maintenance costs, complex system maintenance, and high operating costs for coal-fired boiler systems, and achieve sustainable development, system safety and reliability. Automation-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

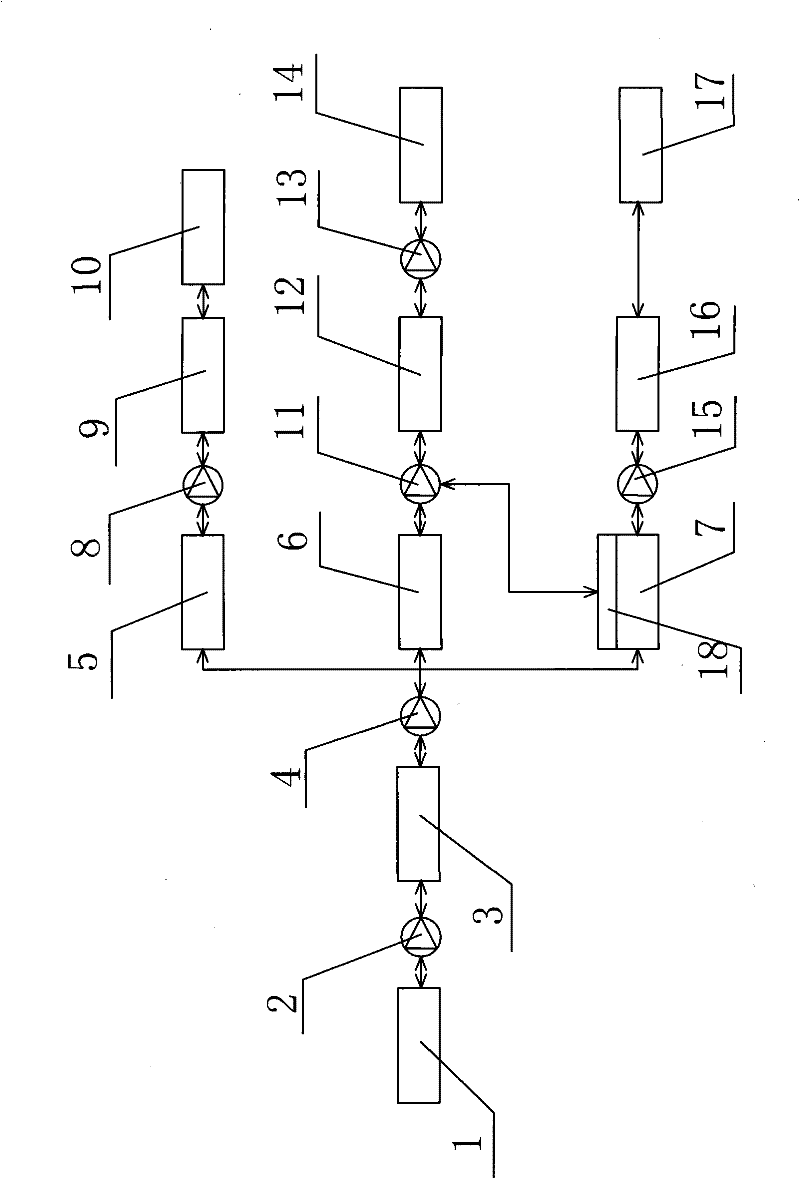

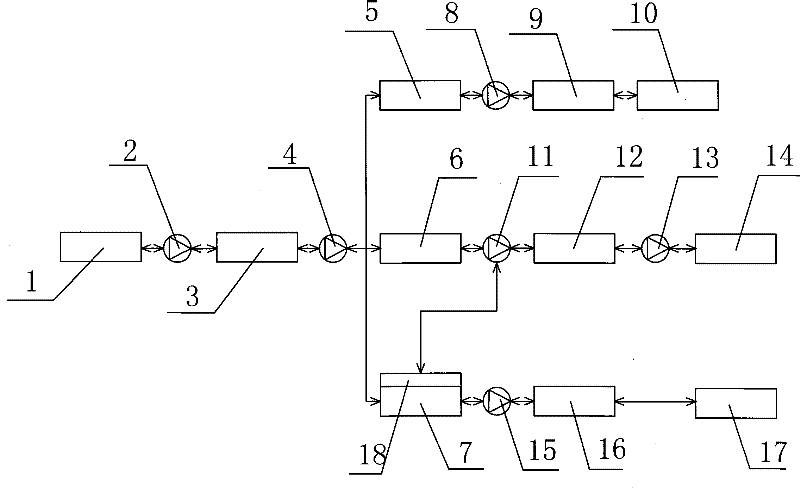

[0020] Example 1: The three systems of wellhead antifreeze, employee bathing, factory building heating and cooling are independent, of which the wellhead antifreezing and employee bathing systems each have 50% unit spare capacity; the factory building heating and refrigeration systems have no spare units, but can be used The spare capacity of the wellhead antifreeze system and employee bathing system provides spare capacity for the heating and cooling system of the factory building. A set of water treatment and water replenishment system is selected to replenish water for the three systems respectively.

[0021] According to this idea, three SRSW-250-2 type water source heat pump units (standard working condition heating capacity is 947.5kW) are selected for the wellhead antifreeze system, dual-purpose and one standby; three SRSW-ZGW-100M-1 type ( Standard working condition heating capacity is 327.4kW) water source heat pump unit, dual-purpose and one standby; factory heating ...

Embodiment 2

[0023] Example 2: The wellhead antifreeze system and the employee bathing system are independent operating systems, but they share a backup water source heat pump unit, the reserve capacity of the employee bathing system is 100%, and the reserve capacity of the wellhead antifreeze system is 40%; the factory building heating and cooling systems It is an independent system without standby unit.

[0024] According to this idea, one SRSW-200-2 type water source heat pump unit (heating capacity of 769.5kW under standard working conditions) is configured for the employee bathing system; two SRSW-250-2 type (heating capacity of 947.5kW) water source heat pump unit; when the heat pump of the employee bathing system or the wellhead antifreeze system fails, the standby unit will supplement the heat source. This backup method is for emergency use; the heating and cooling system of the factory building uses two SRSW-ZGW-400M -4 type (standard working condition heating capacity is 1309.5kW...

Embodiment 3

[0026] Example 3: Two water source heat pump units are used for the wellhead antifreeze system, one water source heat pump unit for full heat recovery is used for the employee bathing system, and two large ones and one small three water source heat pump units are used for the heating and cooling system of the factory building. Among them, the small unit of the factory building heating and cooling system forms a one-way backup with the wellhead antifreeze system and the employee bathing system respectively. Wellhead antifreeze system or employee bathing system for heating. This backup mode is an emergency backup mode, and the original operation mode should be restored immediately after the fault is eliminated.

[0027] In summer, the employee bathing system not only provides employees with hot water for bathing, but also provides free cold sources for air conditioning in mine office buildings and apartment buildings. In this way, during the air conditioning and cooling of mine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com