Composite modified graft starch for textile slurry and preparation method thereof

A technology of grafting starch and textile pulp, applied in textile and papermaking, fiber type, fiber processing and other directions, can solve the problems of long production process and high environmental pressure, achieve good response, excellent performance, and overcome cost concerns Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

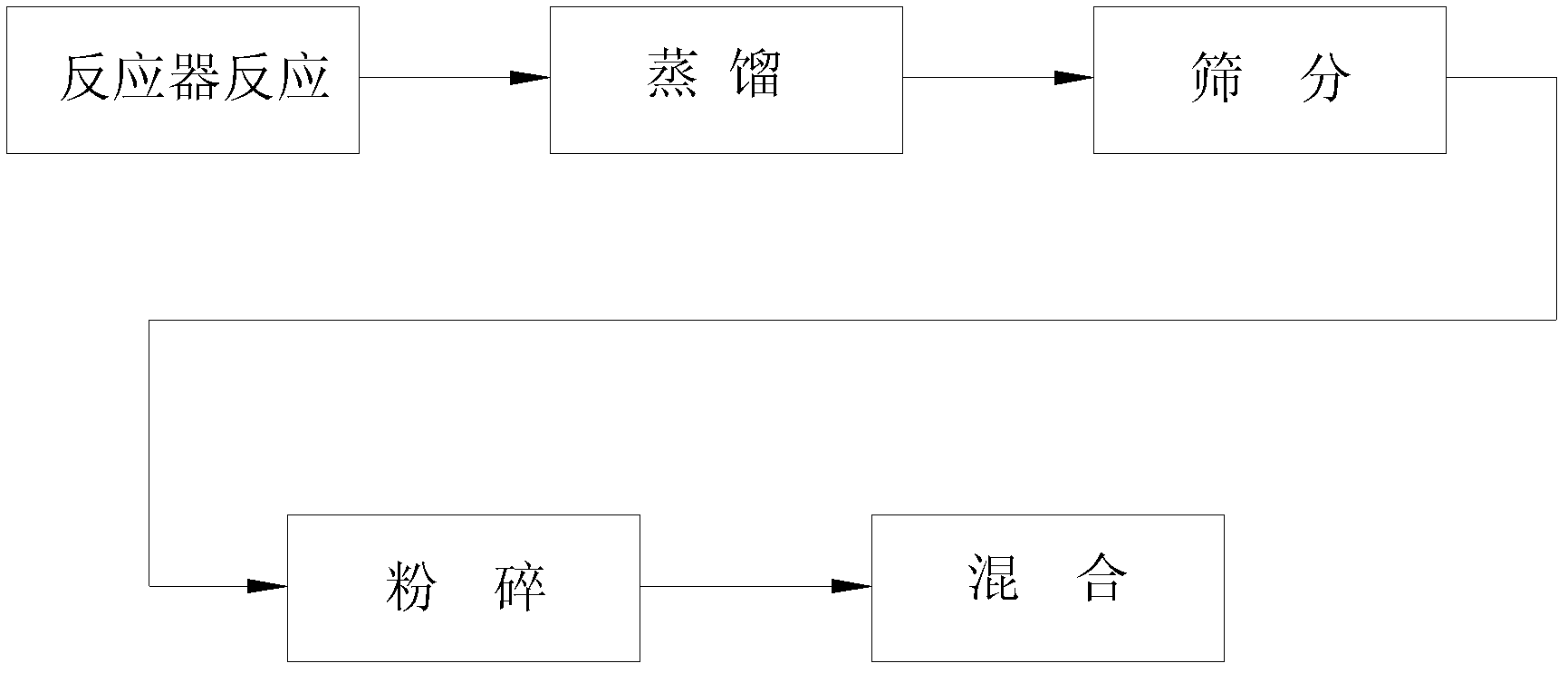

Method used

Image

Examples

Embodiment 1

[0051] A kind of compound denatured grafted starch that textile size is used, its proportioning is:

[0052] Acetate starch 900Kg

[0053] 95% (v / v) alcohol 100Kg

[0054] Acrylamide 40Kg

[0055] Acrylic acid 10Kg

[0056] Vinyl acetate 40Kg

[0057] Caustic soda (sodium hydroxide) 5Kg

[0058] Composite catalyst 0.2Kg

[0059] Final product: 996Kg±5%

[0060] The viscosity requirement of described acetate starch:

[0061] L: 4.0-8.0mPa.S

[0062] M: 8.1-12.0mPa.S

[0063] H: 12.1-16.0mPa.S

[0064] Substitution degree: 0.10±10%.

[0065] The composite catalyst is composed of cerium sulfate and potassium persulfate in a weight ratio of 1:1.

[0066] A kind of preparation method of the compound denatured grafted starch that textile size is used, the step is:

[0067] Add 900kg of acetate starch into a box reactor with a strong stirrer, and heat to 45°C during stirring;

[0068] Composite catalyst 0.2-0.5kg, pre-dissolved with 10Kg of alcohol at a weight ratio of w...

Embodiment 2

[0084] Composite catalyst consumption is 0.52kg, alcohol (volume concentration 98%) consumption 80kg, all the other are with embodiment 1. The effect is the same.

Embodiment 3

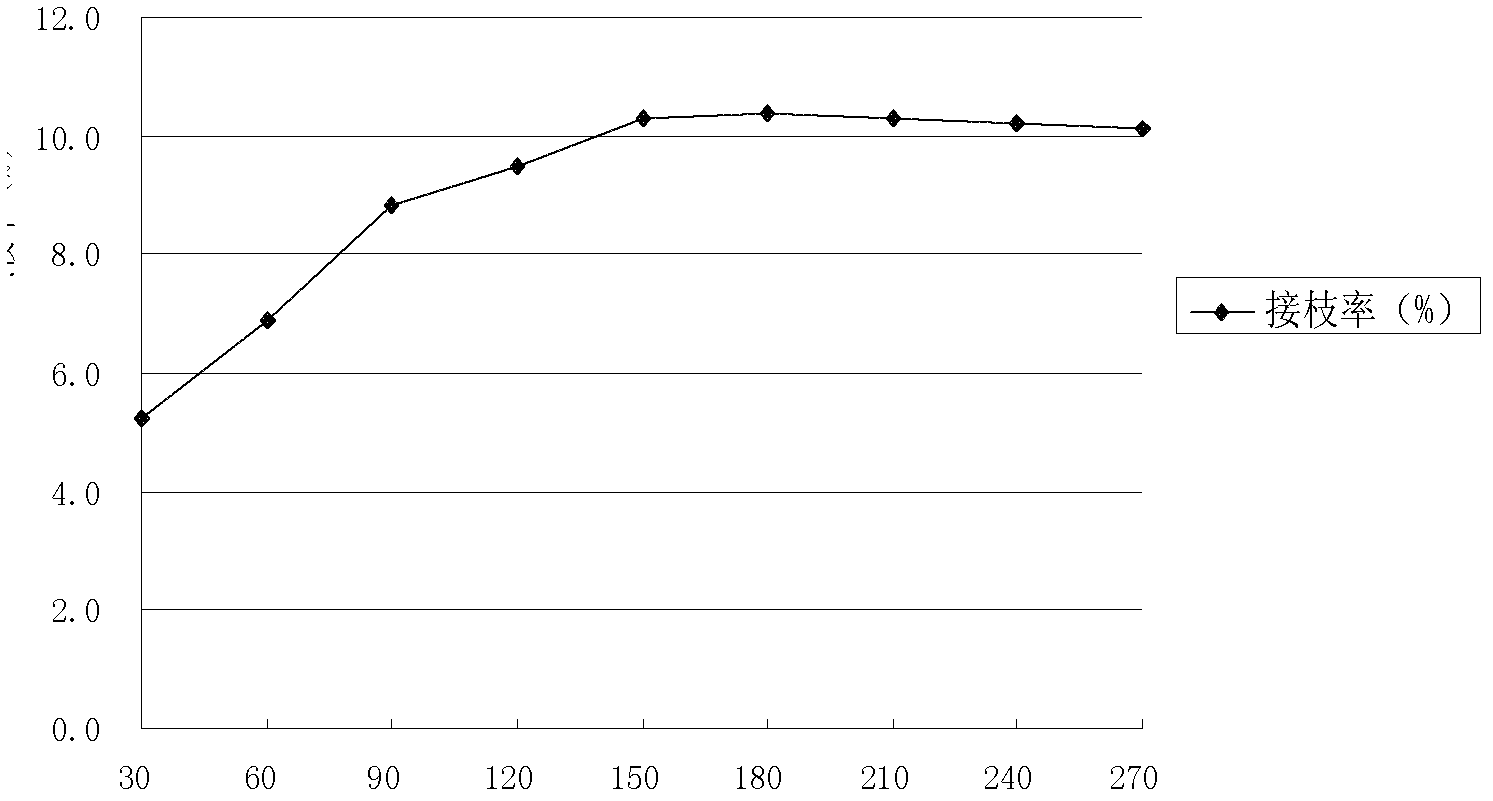

[0086] The reaction temperature was fixed at 45° C., the dosage of the composite catalyst was 0.4 g / 900 g of acetate starch, and the ratio of the remaining raw materials was the same as in Example 1. Under the same stirring speed condition. Sampling in different reaction time periods, then measure the index of grafted starch---grafting rate (calculate the grafting rate of acrylamide with dimethylformamide as extraction solvent), the result is as follows figure 2 shown.

[0087] The grafting rate increased with the prolongation of the reaction time at the initial stage of the reaction. After the reaction reached 150 minutes, the index hardly changed, and the reaction was considered complete. Therefore, the selected reaction time is 150-160min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com