Sludge hydrolysis acidification system

A sludge hydrolysis acidification and sludge technology, applied in the direction of sludge treatment, biological sludge treatment, etc., to achieve the effect of improving dehydration performance, realizing sludge reduction and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Such as figure 1 As shown, the present invention is provided with mud feeding system, sludge hydrolysis acidification tank and circulation heat exchange system.

[0026] The mud feeding system includes a sludge storage tank 1 and a mud feeding screw pump 2 connected to the sludge storage tank 1 at one end.

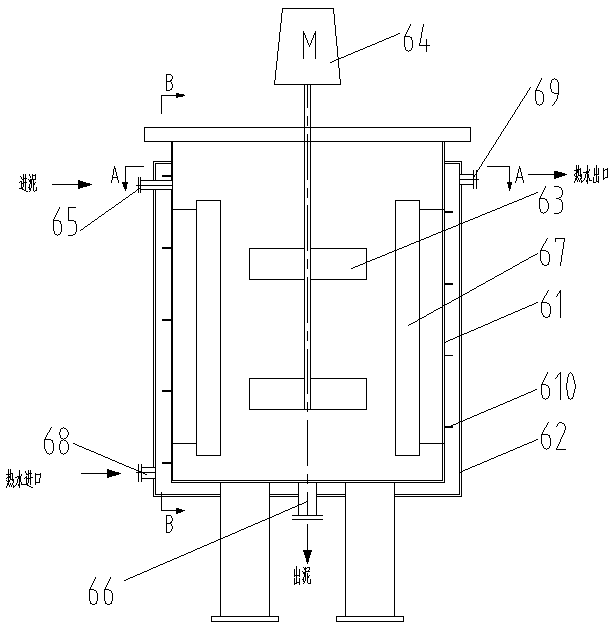

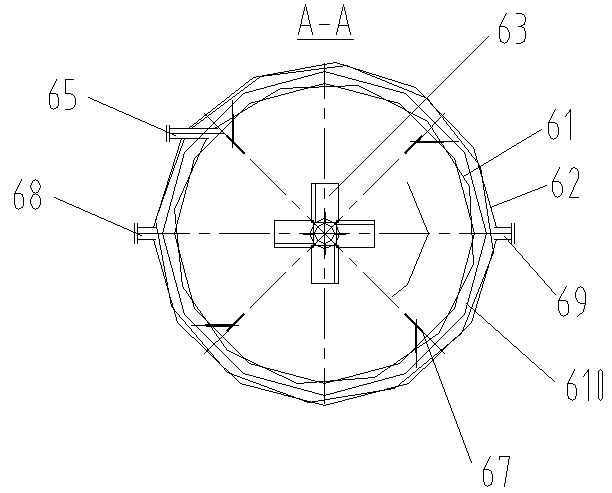

[0027] Such as figure 2 , 3 As shown in and 4 , the sludge hydrolysis acidification tank 6 includes an inner cylinder 61 and a jacket 62 arranged outside the inner cylinder 61 . An agitator 63 is arranged in the inner cylinder 61 , and a motor 64 connected to the agitator 63 is arranged above the sludge hydrolysis and acidification tank 6 . A sludge feed port 65 is provided at the upper end of the inner cylinder 61 , a sludge discharge port 66 is provided at the lower end, and a hollow tangential turbulent plate 67 is provided on the inner wall of the inner cylinder 61 .

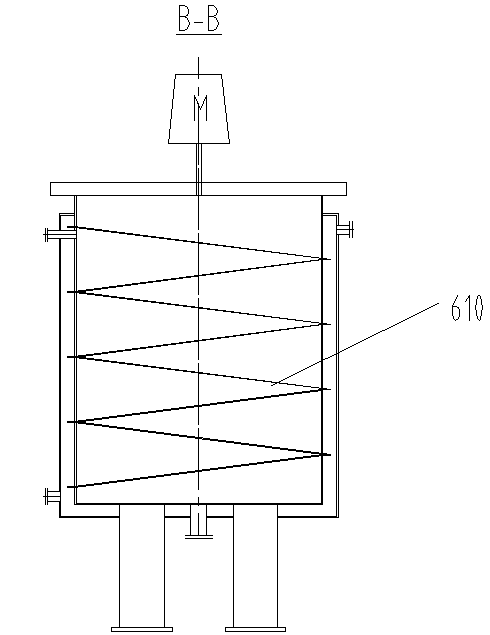

[0028] A spiral deflector 610 is arranged in the jacket 62 , and a hot water inlet 68 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com