Recovering and reutilizing process for papermaking sludge

A technology of papermaking sludge and process, which is applied in the field of sludge reuse, can solve the problems of polluting the environment, wasting land resources, and nowhere to landfill waste sludge, and achieves the goals of low equipment cost, land saving, and production cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

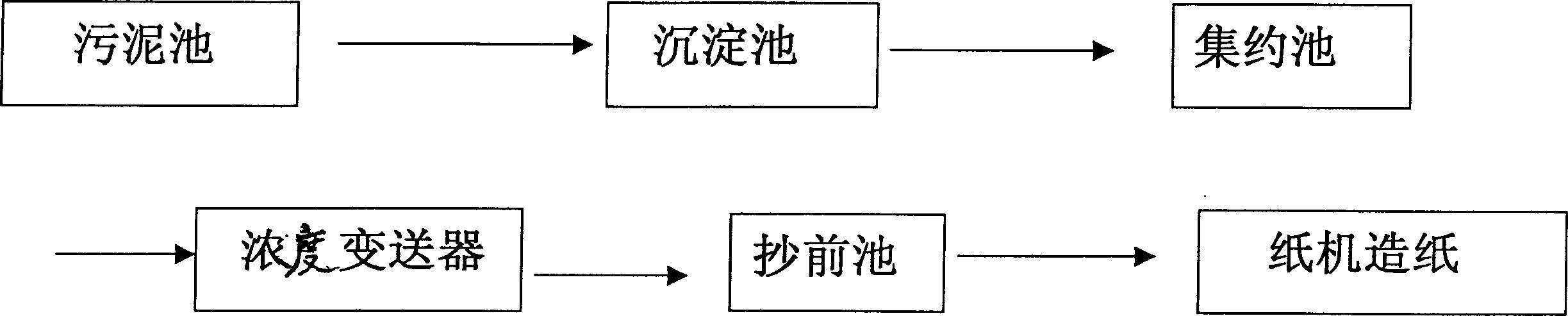

[0012] like figure 1 As shown, the sludge is directly pumped from the sewage treatment tank into the sedimentation tank for sedimentation; after half an hour of sedimentation, it is put into clear water to make it a usable slurry with a certain concentration; it is then pumped into the intensive tank to adjust the concentration before printing; Concentration transmitter control, so that the concentration is controlled at 3%. After adjustment, it is sent to the forebay and mixed with good pulp to form a mixed pulp before going online. The pulp pump sends it to the online high-level box for papermaking. The concentration is 3%. This process makes the waste that originally flows into the river and needs to be treated and piled up become a good raw material for the sustainable development of the paper industry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com