Hydrogen metallurgy method

A technology for hydrogen metallurgy and hydrogen enrichment, applied in the fields of metallurgy and energy, can solve the problems of reducing production efficiency, heat energy utilization rate of less than 40%, cost and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

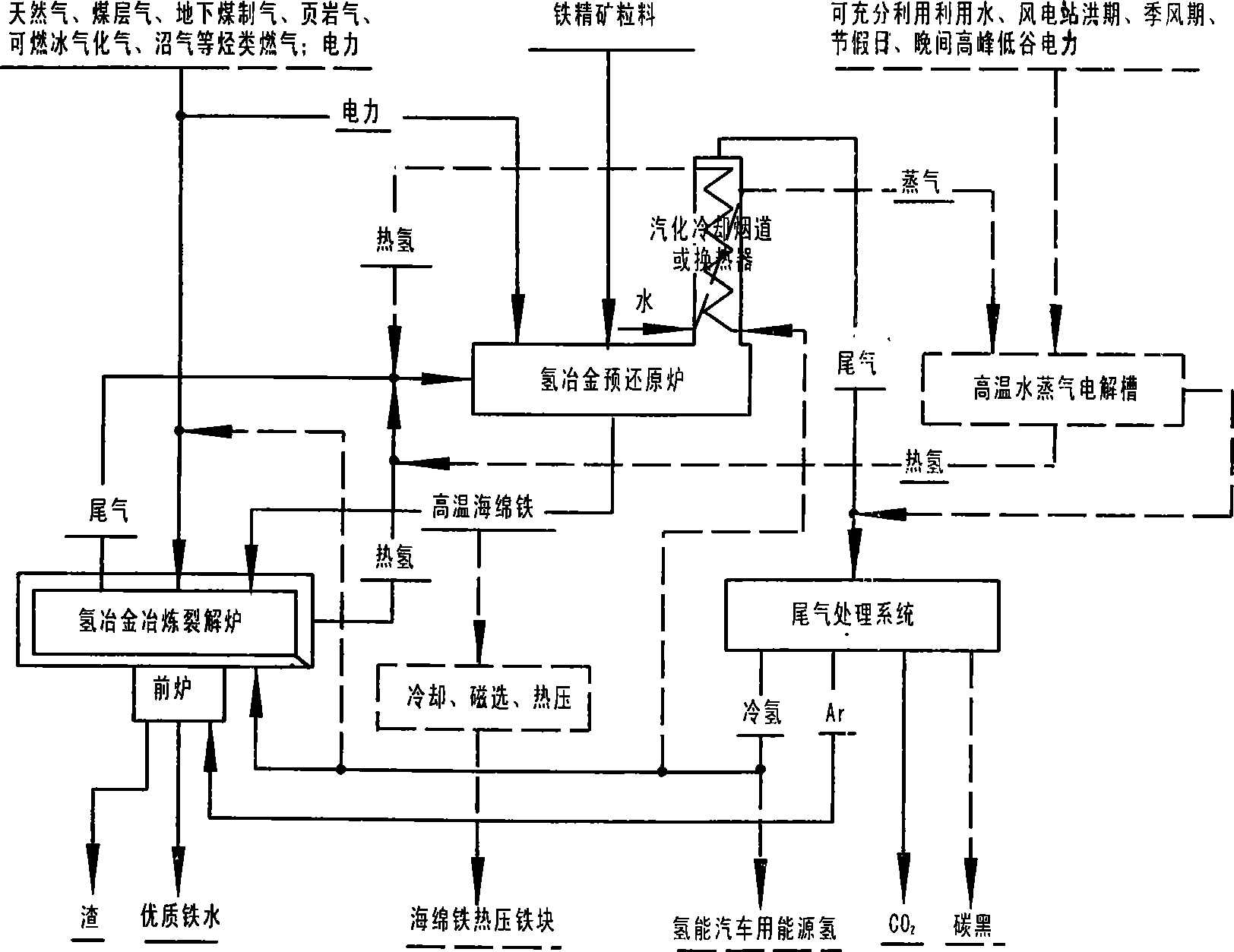

[0072] Embodiment one, "hydrocarbon gas cracking hydrogen metallurgy such as natural gas or coalbed methane" embodiment (attached figure 1 , the dotted line in the figure indicates: raw materials for hydrogen production that can be used, peak and low power of hydro-wind power stations that can be used, processes that can be increased or applied, and products that can be produced):

[0073] Raw materials for ironmaking: selected iron ore concentrate powder in Anshan, Liaoning, China: TFe66.3%, MnO0.3%, SiO 2 1.2%, Al2031.03%, CaO1.79%, MgO0.79%, S0.02%, P0.017%. Particle size of 200 mesh accounts for 90%; this is a typical selected iron ore concentrate powder in the market, not a specially processed iron ore concentrate ultrafine powder. When using the "electrically supplementary heating fluidized bed" or other fluidized beds proposed in No. 200610106689.1 patent application as "hydrogen metallurgy pre-reduction furnace" for pre-reduction, this dry fine ore can be directly use...

Embodiment 2

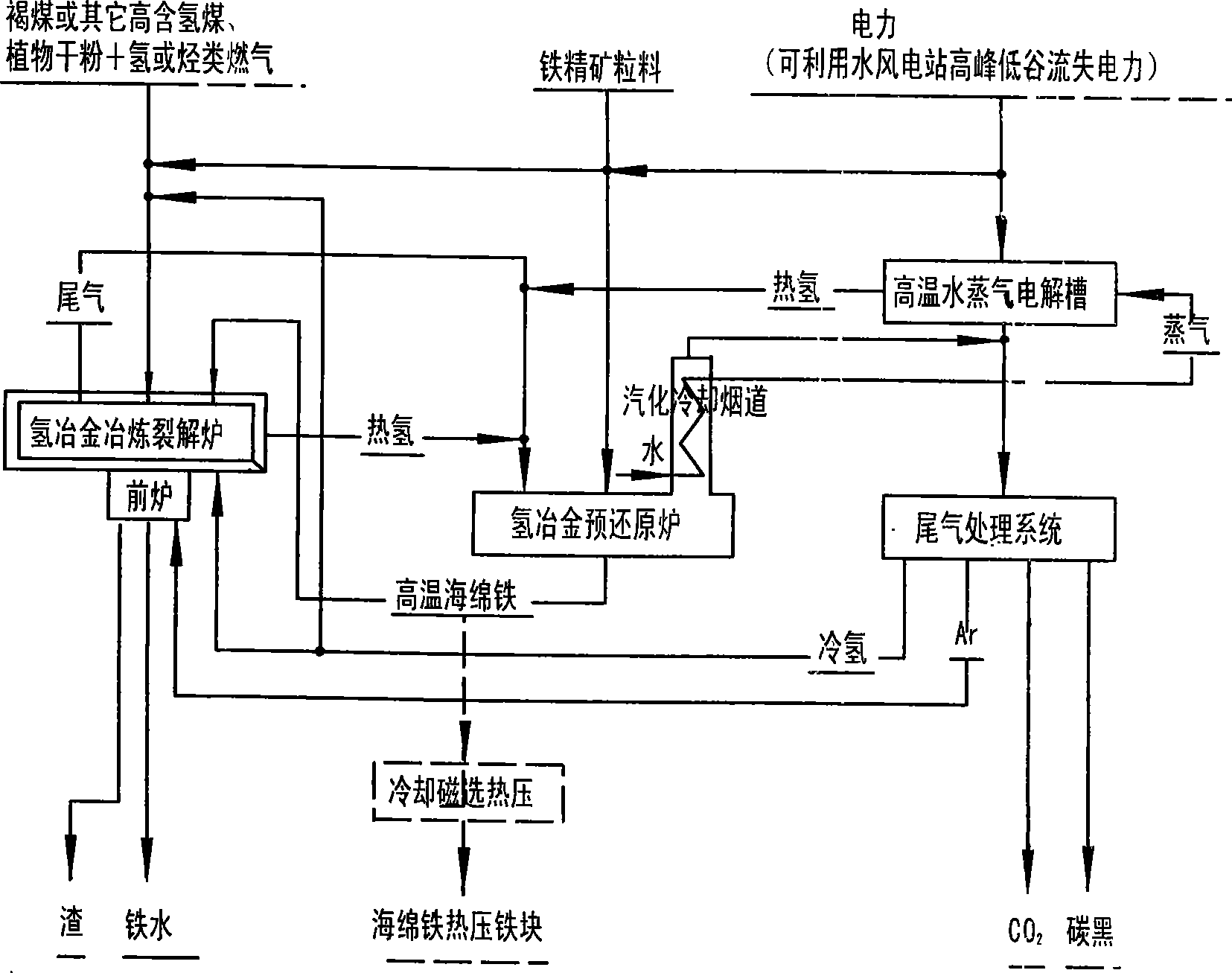

[0082] Embodiment 2, "Lignite and other high hydrogen-containing coal or plant dry powder pyrolysis hydrogen metallurgy" embodiment, attached figure 2 :

[0083] Raw materials for ironmaking: common iron concentrate lump ore pellets in the market: TFe62.5%, SiO24.5%, Al2032.9%, S0.02%, P0.07%. Particle size 5 ~ 10mm. It can also use various iron ore fine powders in the domestic and international markets, including selected iron ore concentrate powders with a particle size of <0.1mm, and 10-20mm iron ore concentrate drying and dehydrating pellets made with a small amount of binder.

[0084] Raw material for hydrogen production: a dry powder of washed, dried and milled lignite, composition (wt): C69.1%, H5.5%, O20.8%, N1.4%, S0.1%, ash 2.5%, coal powder particle size <0.1mm; chopped, dried and milled plant dry powder with water content ≤1% and the same particle size can also be used. The ratio of feeding into the furnace is 100kg / t of finely washed lignite dry powder or 150k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com