Vacuum salt producing technique of salt-field saturated bittern direct ingress into evaporation tank

A technology of vacuum salt production and evaporation tank, which can be used in sustainable manufacturing/processing, chemical industry, alkali metal chloride, etc., and can solve the problems of increasing raw salt consumption, high cost, and affecting people's lives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

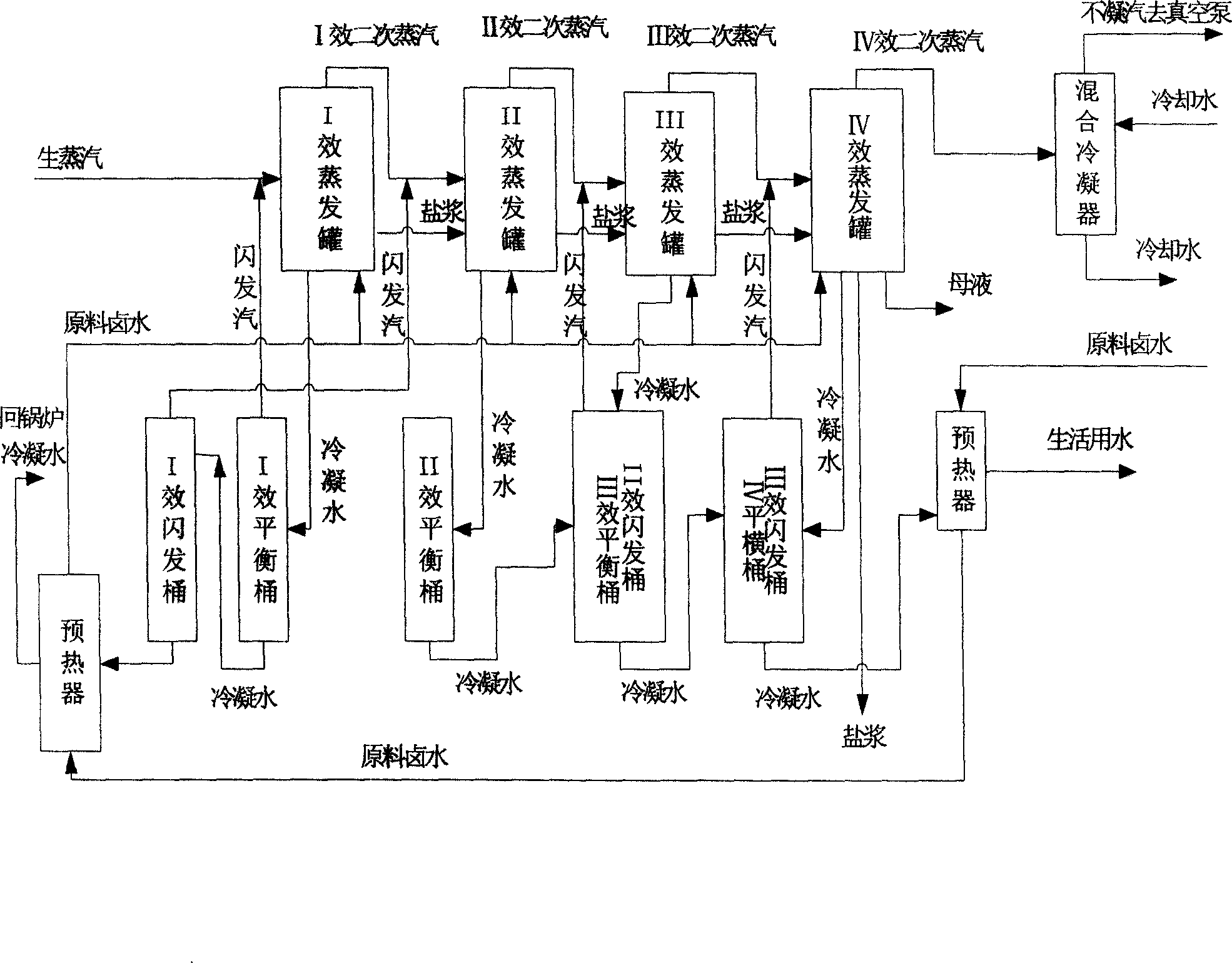

[0023] The inventor has designed a production line for a certain enterprise with an annual output of 150,000 tons of salt field saturated brine directly entering the evaporation tank for vacuum evaporation to produce refined salt. The description is as follows in conjunction with the accompanying drawings:

[0024] The production line consists of brine preparation, vacuum evaporation, salt washing, centrifugal dehydration, drying, iodine addition, packaging and other processes: brine preparation:

[0025] The brine is evaporated by the sun in the beach field until it is saturated (not lower than 24°Be', and the ratio of sodium to magnesium should not be lower than 5), and is stored in a saturated brine storage. After the brine settles and clarifies for 24 hours, it is poured into the concentration tank (There is raw salt in the thickening pool) to increase the concentration of brine, and then put it into the clear brine barrel.

[0026] Vacuum evaporation:

[0027] The satura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com