Technology of extracting dihydrogen cannabinol (CBD) from industrial cannabis sativa

A technology of industrial hemp, cannabidiol, applied in the biological field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

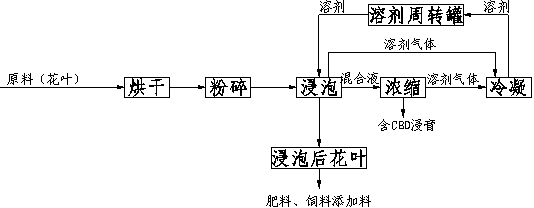

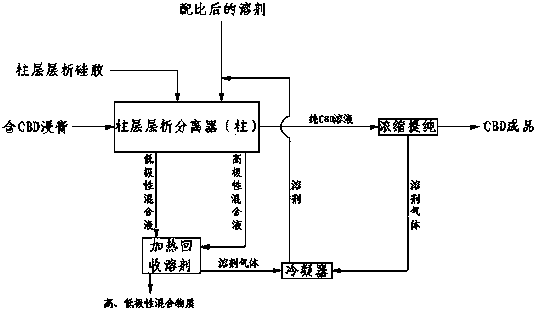

[0025] Embodiment 1: A process for extracting dihydrocannabinol (CBD) from industrial hemp, characterized in that the process is achieved through the following steps:

[0026] In the first step, the raw materials are flowers and leaves in the full flowering stage. At this time, the content of CBD is relatively high. The flowers and leaves are pre-dried or baked, the water content is between 10% and 15%, and the dust content is below 3%. Put the raw materials into the baking equipment, control the temperature between 130-160°C, and control the time for 15-35 minutes. The purpose of drying is to bake the moisture in the flowers and leaves to between 3 and 5%, and the other purpose is to promote the post-ripening period of CBD. This process can increase the amount of CBD extracted, and the heat source can be heat transfer oil, electricity, steam, etc.

[0027] The second step is to grind the dried flowers and leaves to 5-10 meshes, which can expand the contact surface area betwe...

Embodiment 2

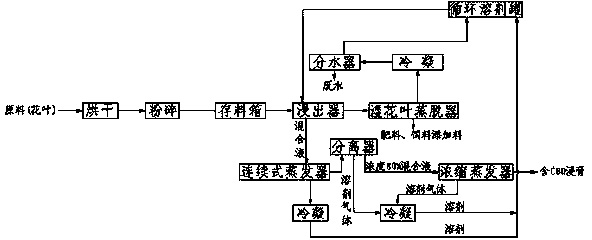

[0038] Embodiment 2: A process for extracting dihydrocannabinol (CBD) from industrial hemp, which is extracted by continuous soaking, characterized in that the process is realized through the following steps:

[0039] In the first step, the raw materials are flowers and leaves in the full flowering stage. At this time, the content of CBD is relatively high. The flowers and leaves are pre-dried or baked, the water content is between 10% and 15%, and the dust content is below 3%. Put the raw materials into the baking equipment, control the temperature between 130-160°C, and control the time for 15-35 minutes. The purpose of drying is to bake the moisture in the flowers and leaves to between 3 and 5%. Another purpose is to promote the post-ripening period of CBD. This process can increase the extraction amount of CBD. The heat source can be heat transfer oil, electricity, steam Wait.

[0040]The second step is to grind the dried flowers and leaves and store them in the storage b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com