Concentrator-integrated screw press

A technology for screw presses and thickening devices, applied in presses, presses using rotating pressure components, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of concentrated sludge retention, dehydration decline, and screw press dehydration Efficiency drop and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

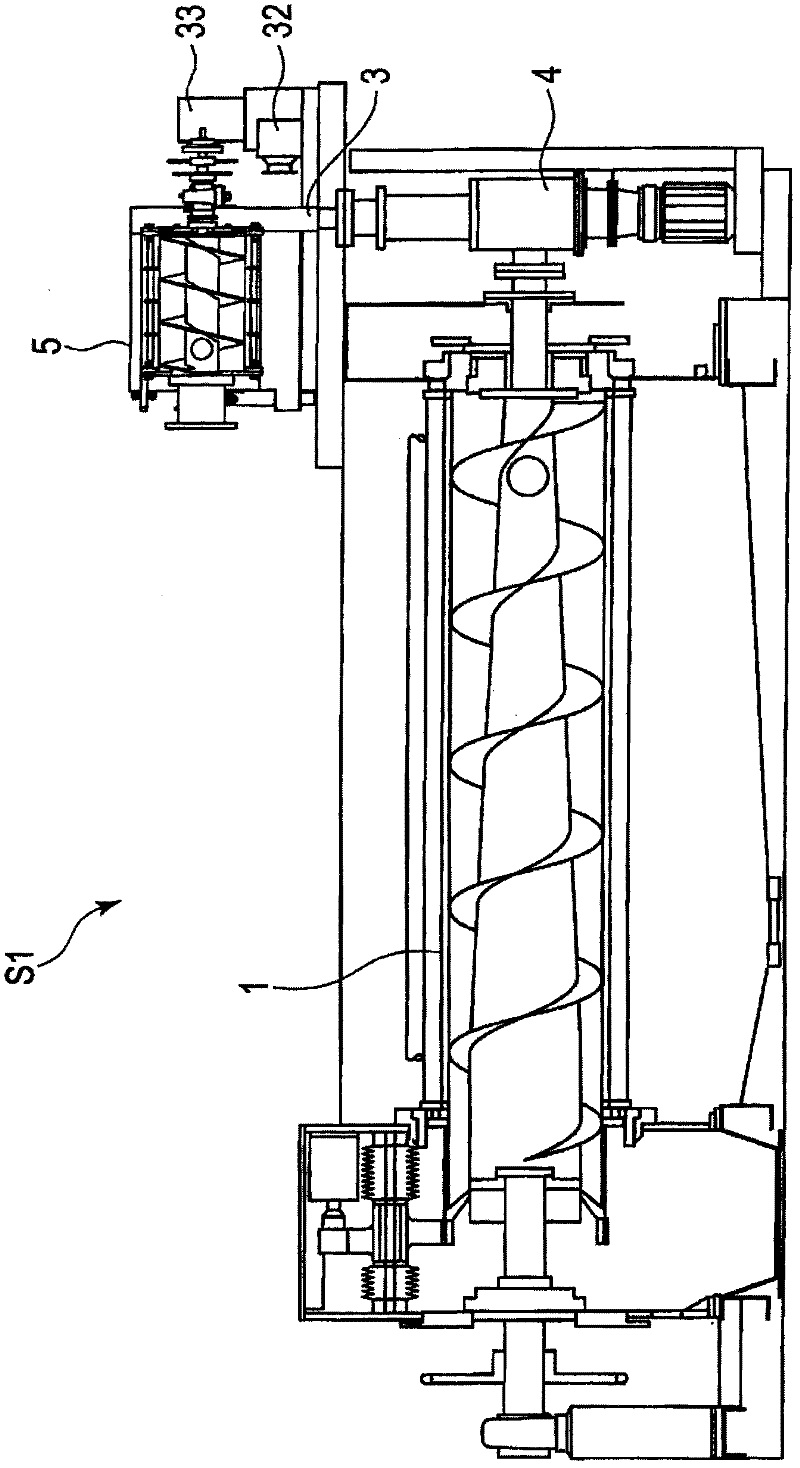

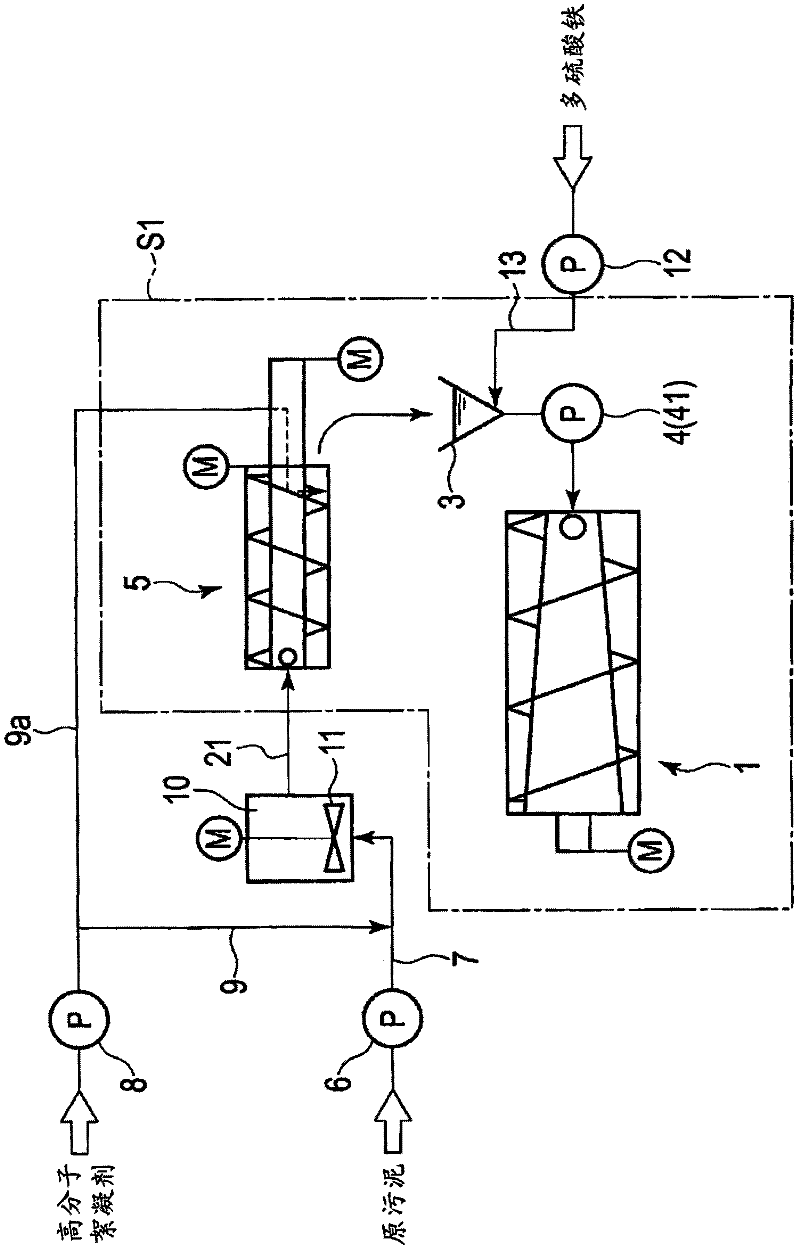

[0034] figure 2 It is a longitudinal sectional side view of the concentrator-integrated screw press S1 according to the first embodiment of the present invention. Concentrating device-integrated screw press S1 employs a rotary concentrator 5 as the concentrating device 2 of the above-mentioned concentrating-device-integrated screw press S. That is, the concentrating device-integrated screw press S1 includes: a screw press 1 , a rotary concentrator 5 mounted on the screw press 1 , and a discharge unit connected to the rotary concentrator 5 to receive concentrated water discharged from the rotary concentrator 5 . The chute 3 for sludge is vertically arranged at the beginning of the screw press 1 and presses the concentrated sludge received by the chute 3 into the press-in pump 4 of the screw press 1 . The chute 3 is connected to the suction side of the push pump 4 , and the screw press 1 is connected to the discharge side of the push pump 4 .

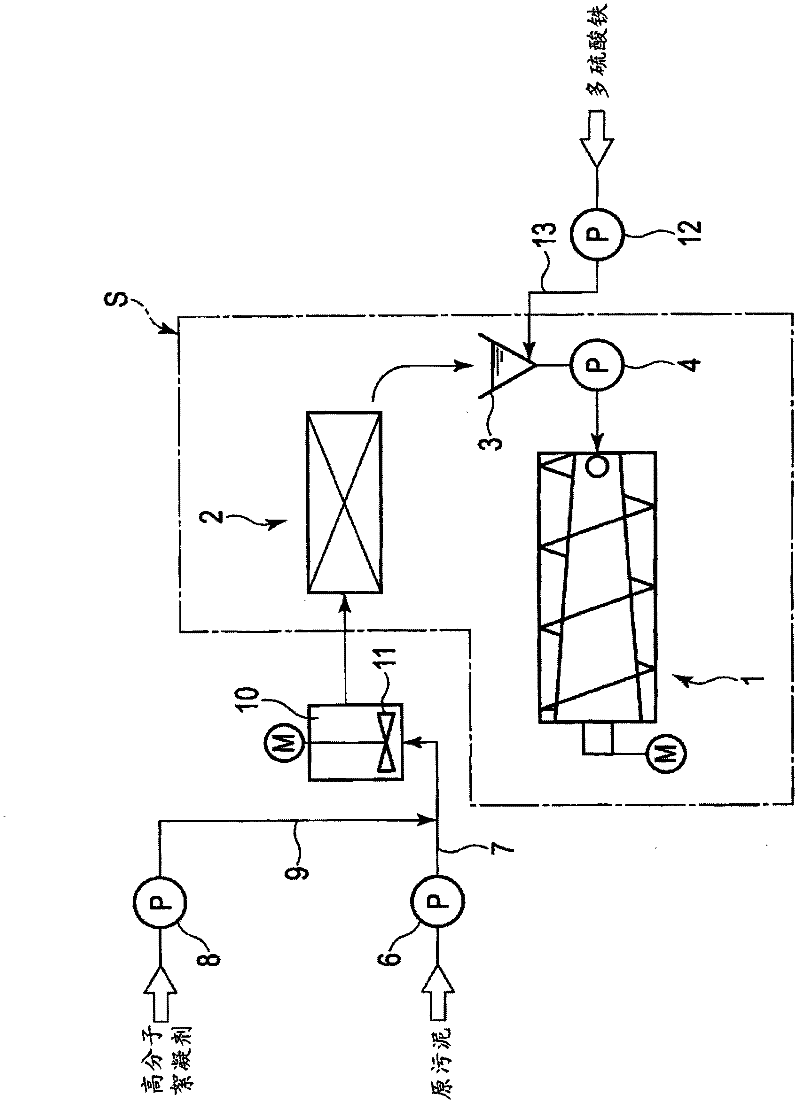

[0035] image 3 It is a flow c...

no. 2 approach

[0074] Figure 13 It is a longitudinal sectional side view of the concentrator-integrated screw press S2 according to the second embodiment of the present invention. The thickening device-integrated screw press S2 is different from the first embodiment in that the thickening device 2 is not composed of the rotary thickener 5 but is composed of a belt thickener 81 and a thickened sludge storage tank 82 .

[0075] The thickening-device-integrated screw press S2 includes a screw press 1, a belt-type thickener 81 arranged at the front stage of the screw press 1, a concentrated sludge storage tank 82 arranged at the discharge part of the belt-type thickener 81, and a The discharge part of the concentrated sludge storage tank 82 is connected to and accepts the chute 3 of the concentrated sludge discharged from the concentrated sludge storage tank 82, and is vertically arranged at the beginning of the screw press 1 and presses the concentrated sludge received by the chute 3 into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com