A screw press type filter for wastewater treatment

A technology of dehydrator and screw, which is applied in the field of livestock industry, can solve the problems such as the reduction of treatment efficiency, and achieve the effect of improving dehydration efficiency and wastewater treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

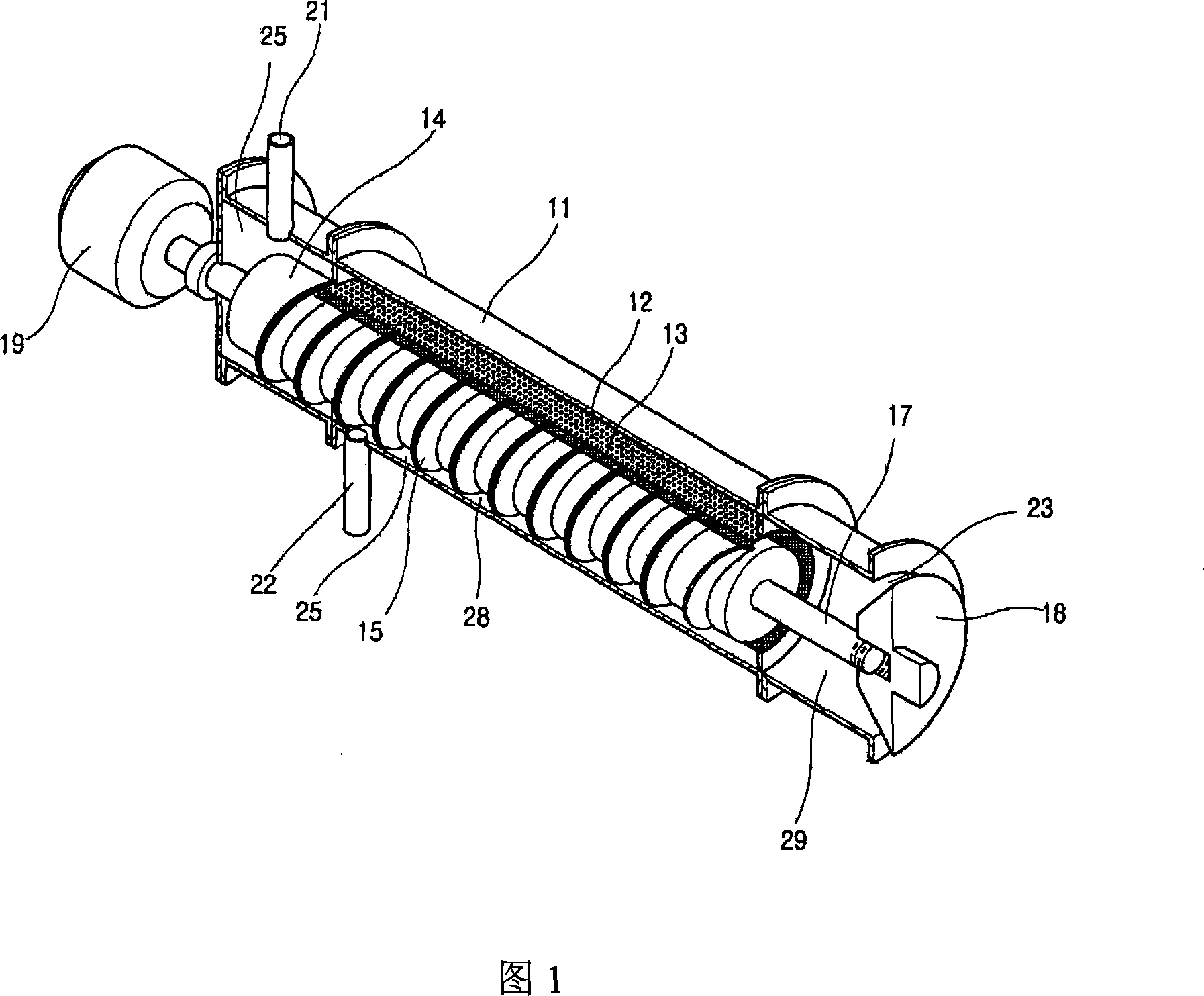

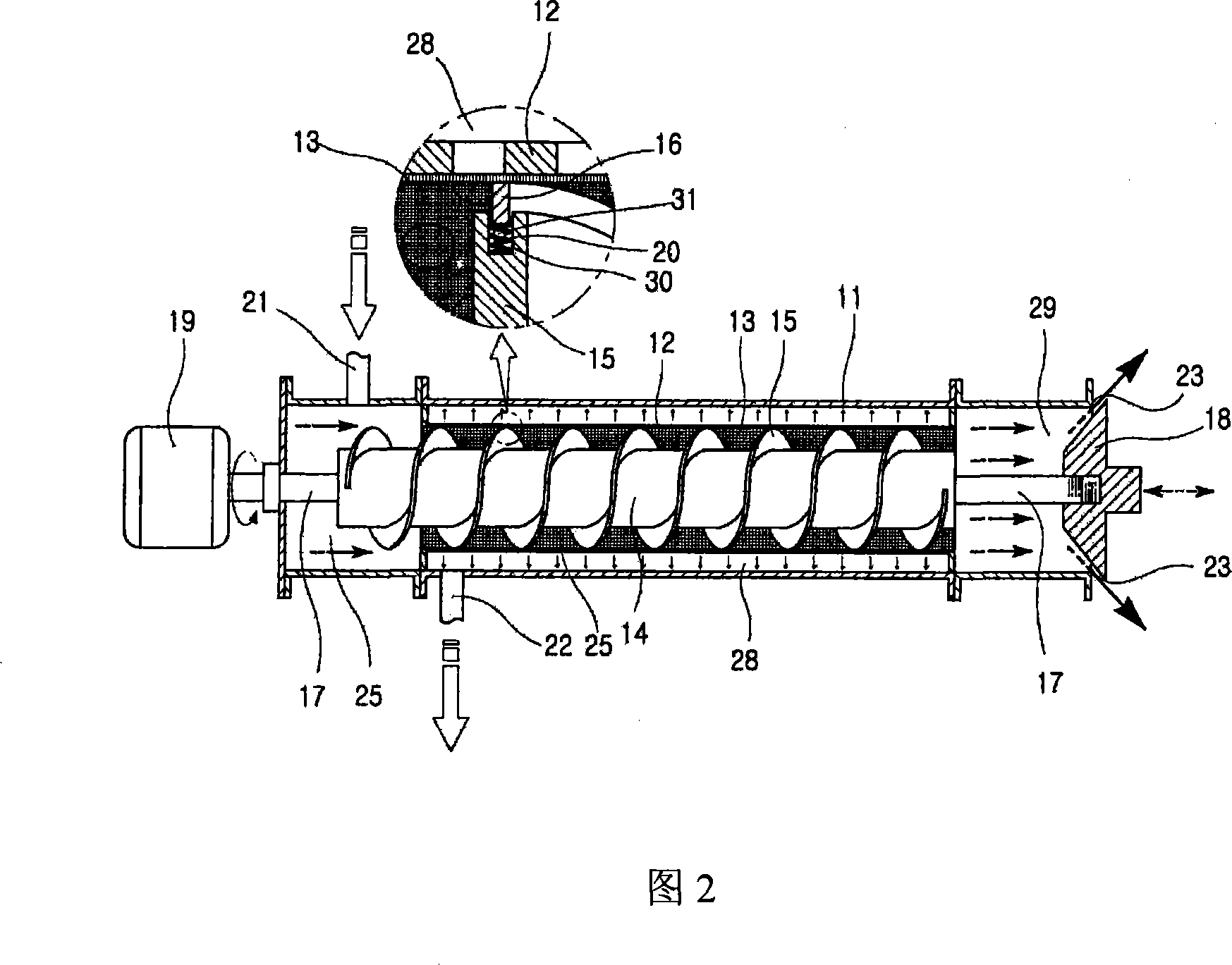

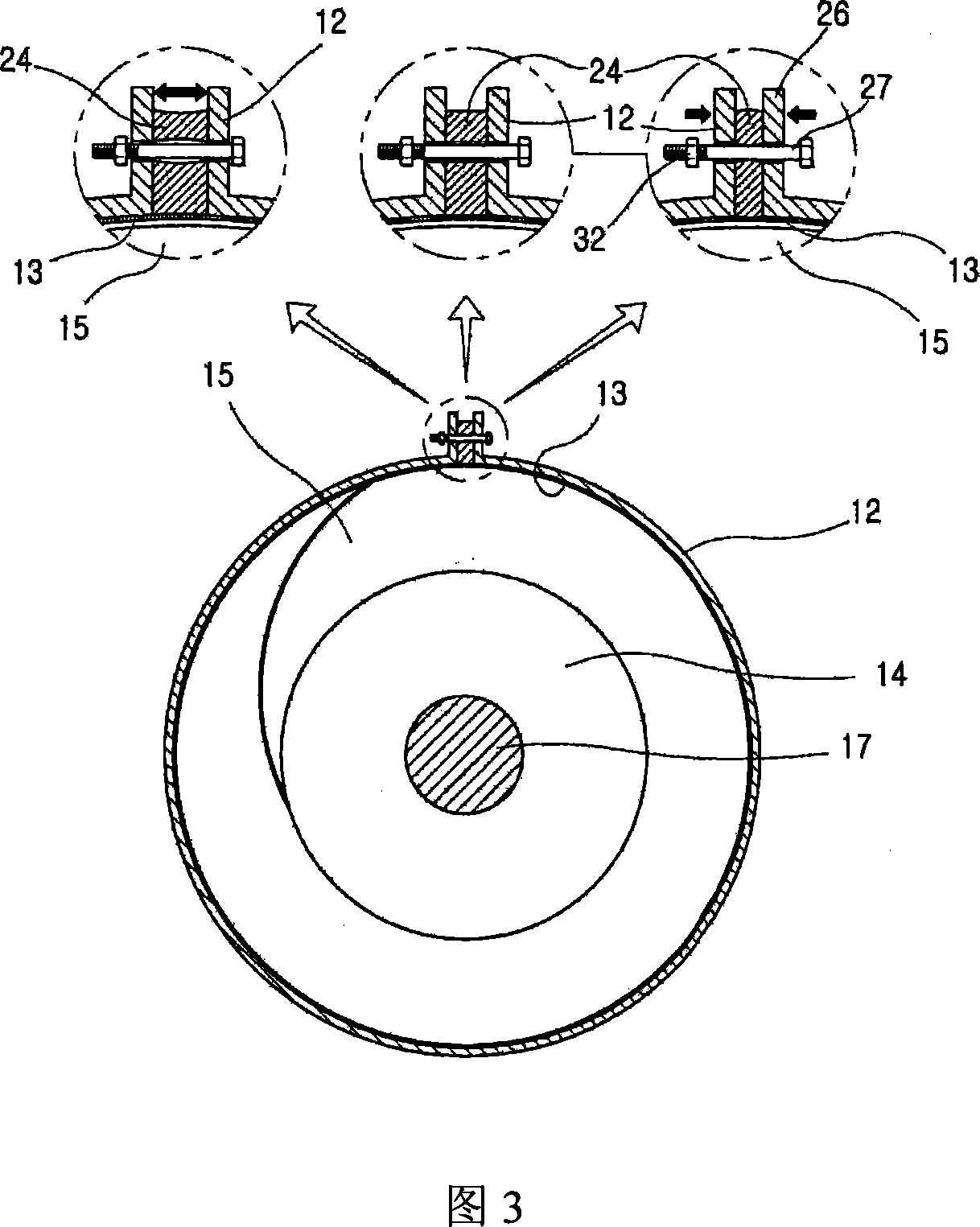

[0019] The screw pressure dehydrator of the present invention will be described more fully hereinafter with reference to the accompanying drawings, which show representative embodiments of the invention.

[0020] As shown in FIGS. 1 and 2 , the screw pressure dehydrator has an outer cylinder 11 including a pressurized chamber 25 , a liquid substance discharge chamber 28 and a lump discharge chamber 29 . On the pressurization chamber 25 there is a waste water inlet 21 through which waste water flows. On the liquid substance discharge chamber 28, there is a liquid substance outlet 22 for discharging the escaped liquid substance. There is a lump outlet 23 on the lump discharge chamber 29 , a portion of which has an opening, through which lumps formed of compressed solid matter are discharged.

[0021] A porous cylinder 12 is provided inside the liquid substance discharge chamber 28 , and a metal filter 13 is joined on the inner circumference of the porous cylinder 12 .

[0022]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com