Screw press

A screw press and screw technology, which is applied in the field of screw presses, can solve the problems of poor equipment reliability, large contact area, and high energy consumption of equipment, and achieve the effects of increased torque, effective operating speed, and reduced rotational speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

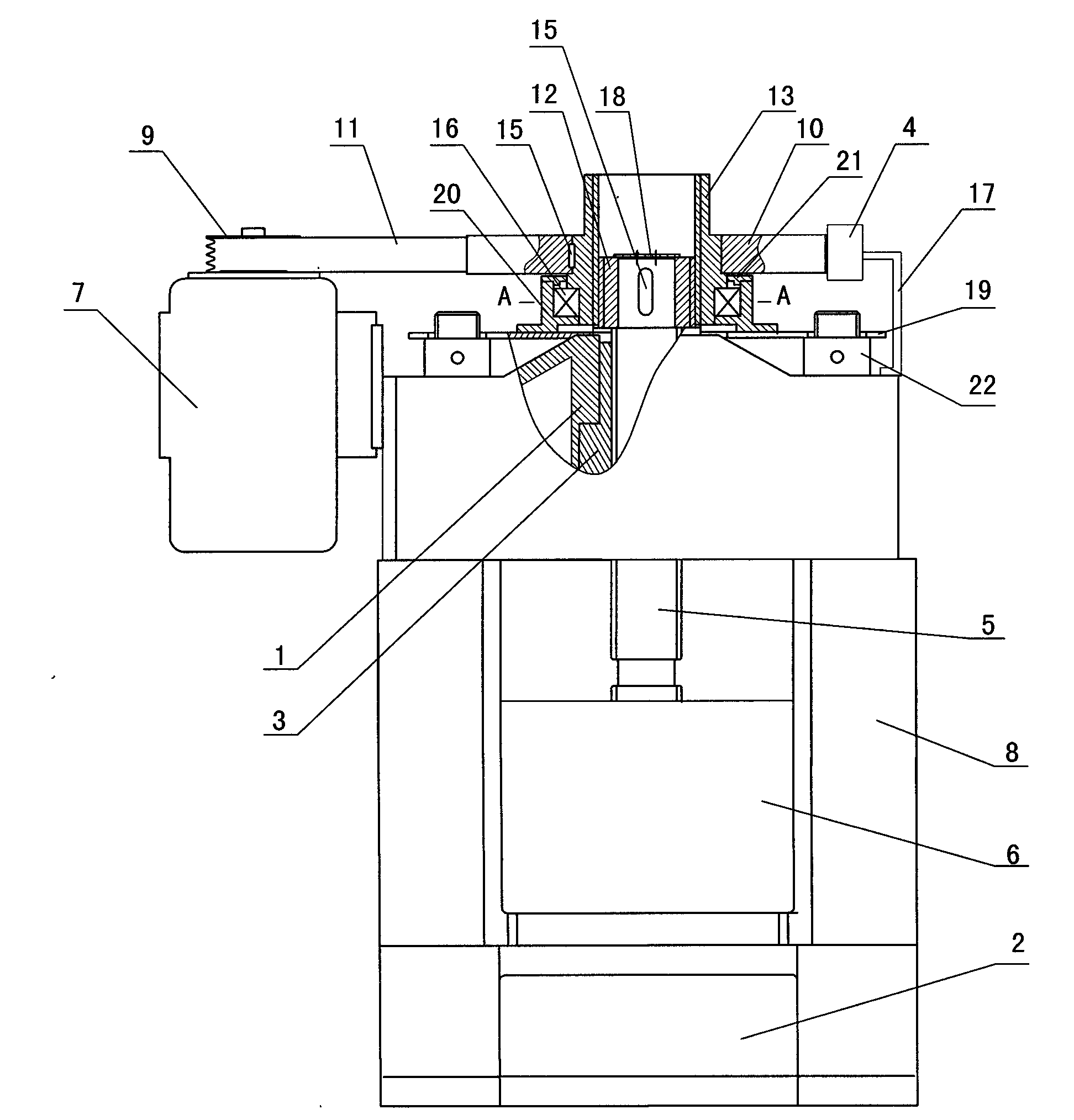

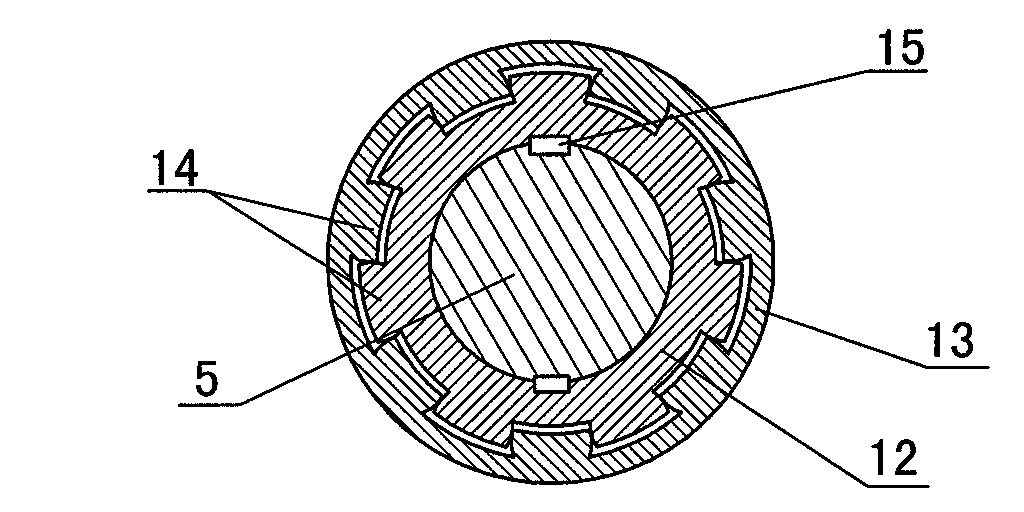

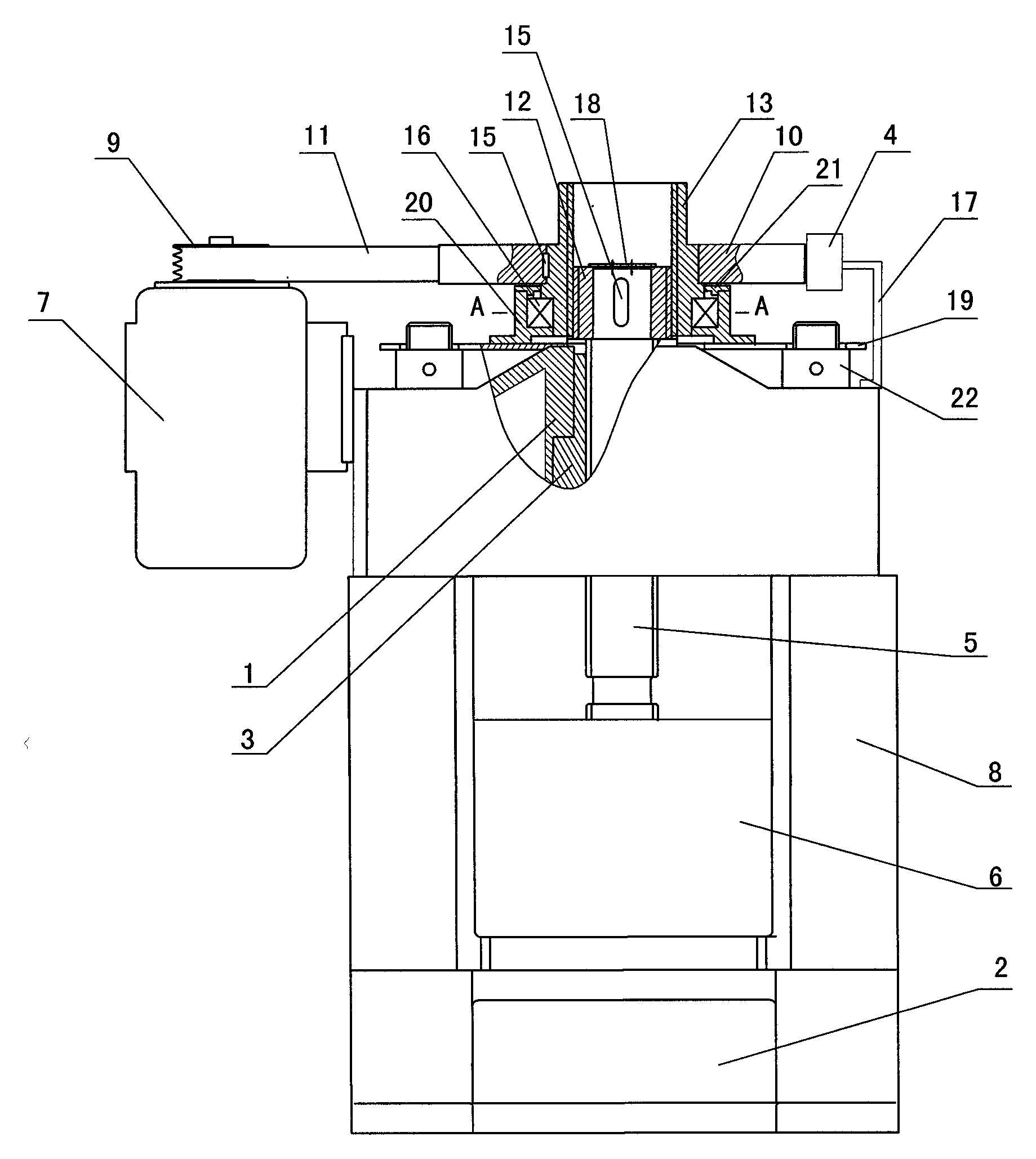

[0016] exist Figure 1-2 In the shown embodiment: the column 8 is vertically connected between the upper beam 1 and the lower beam 2, the nut 3 is fixed on the upper beam 1 and screwed with the screw 5, and the bottom of the screw 5 is provided with a slider 6; the transmission mechanism includes The small pulley 9, the large pulley 10, the belt, the inner sleeve 12 and the outer sleeve 13 connected by splines, wherein the outer wall of the inner sleeve 12 and the inner wall of the outer sleeve 13 are evenly distributed with outwardly protruding straight teeth 14 of exactly the same shape and number. , the tooth profile of the outer convex straight teeth 14 is an involute, and the outer convex straight teeth 14 on the inner sleeve 12 and the outer sleeve 13 mesh with each other to form a line contact sliding fit; the inner sleeve 12 is set on the upper end of the screw rod 5 through the key 15, and the inner sleeve 12 and the top of the screw rod 5 are provided with a pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com