Manufacturing method of new-energy automobile drive motor shaft

A new energy vehicle and drive motor technology, applied in the field of metal parts processing, can solve the problems of low material utilization rate, low processing efficiency, poor tooth shape strength and poor service life, and achieves optimization of Fr and FP values, high product strength and precision. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

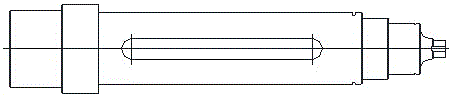

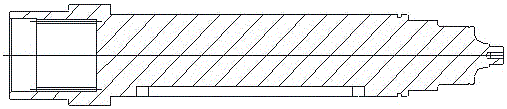

Image

Examples

Embodiment 1

[0036] The preparation method of the drive motor shaft of the new energy vehicle of the present invention is characterized in that it comprises the following steps:

[0037] The preparation method of the new energy vehicle drive motor shaft of the present invention, the specific processing technology is as follows:

[0038] 1. Billet hot forging manufacturing: According to the process requirements, select the billet, heat the billet to the range of 1050°C-1150°C, and forge the billet on the electric screw press to obtain the pre-forged billet; if the intermediate frequency heating furnace is used to heat the billet to 1050°C In the range of ℃-1150℃, die forging is formed on a 1000T electric screw press to obtain a pre-forged billet.

[0039] 2. The pre-forged blank adopts the method of spheroidizing and normalizing (manufacturing). The required temperature range is 650°C-680°C, and the time is 150-250 minutes, and then it is rapidly cooled to 500°C-550°C with strong wind, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com