Method for preparing hydrophobic micro-structure on surface of organic glass through femtosecond laser

A technology of plexiglass and femtosecond laser, which is applied in the manufacture of microstructure devices, microstructure technology, microstructure devices, etc., can solve the problems of difficulty in obtaining hydrophobic surfaces and long time consumption, and achieve low material cost, high preparation efficiency, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

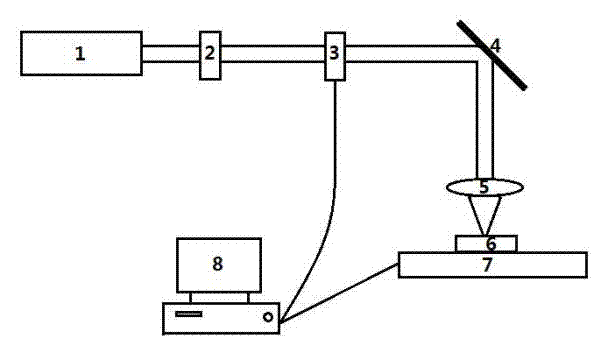

[0030] The laser pulse parameters emitted by the femtosecond laser are as follows: the pulse width is 120 fs, the wavelength is 800 nm, the pulse frequency is 1 kHz, and the single pulse energy is 3 mJ. These pulses are focused on the plexiglass surface by a 20X (N.A=0.45) objective lens, and the spot diameter of the femtosecond laser is 10 μm. When the femtosecond laser irradiates the plexiglass, the material in the laser irradiated area will be ablated, resulting in obvious structural changes, so that a periodic microstructure can be formed on the surface of the plexiglass through laser scanning.

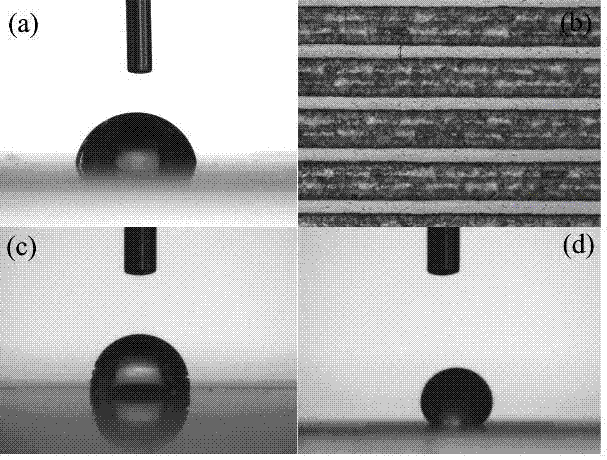

[0031] refer to figure 2 As shown, (a) is the photo of the static contact angle of water droplets on the plexiglass surface that has not been irradiated by femtosecond laser, and the value is 79.5°. This result shows that the plexiglass surface is hydrophilic at this time; The micro-optical photo of the microstructure obtained by the second laser line scanning method on the surf...

Embodiment 2

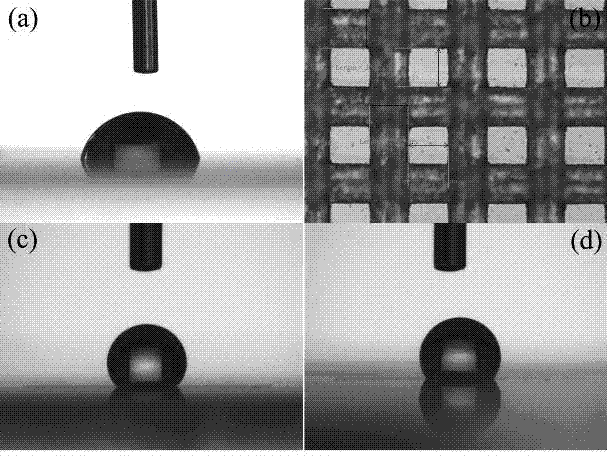

[0033] This example is basically the same as Example 1, except that periodic fringes are first obtained by a line scan with a line width of 30 μm and a spacing of 30 μm. After completion, the sample is rotated 90°, and the scan is repeated once with the parameters just now. , forming an orthogonal structure, the result is as follows image 3 shown. (a) is the photograph of the static contact angle of water droplets on the plexiglass surface that has not been irradiated by femtosecond laser, and the value is 81.0°; (b) is the micro-optics of the microstructure obtained by the femtosecond laser surface scanning method on the plexiglass surface Photos; (c) and (d) the contact angle measurement results of the microstructured surface in two mutually perpendicular directions, (c) 133.3° and (d) 126.6°. Directly written orthogonal microstructure domains exhibit very uniform hydrophobicity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Stripe width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com