Pot container

A tank container and tank body technology, which is applied in the directions of tank trucks, packaging, transportation and packaging, can solve problems such as unsatisfactory heating effect, limited loading volume, and inability to withstand internal pressure, so as to improve transportation efficiency and economic benefits. Material saving, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

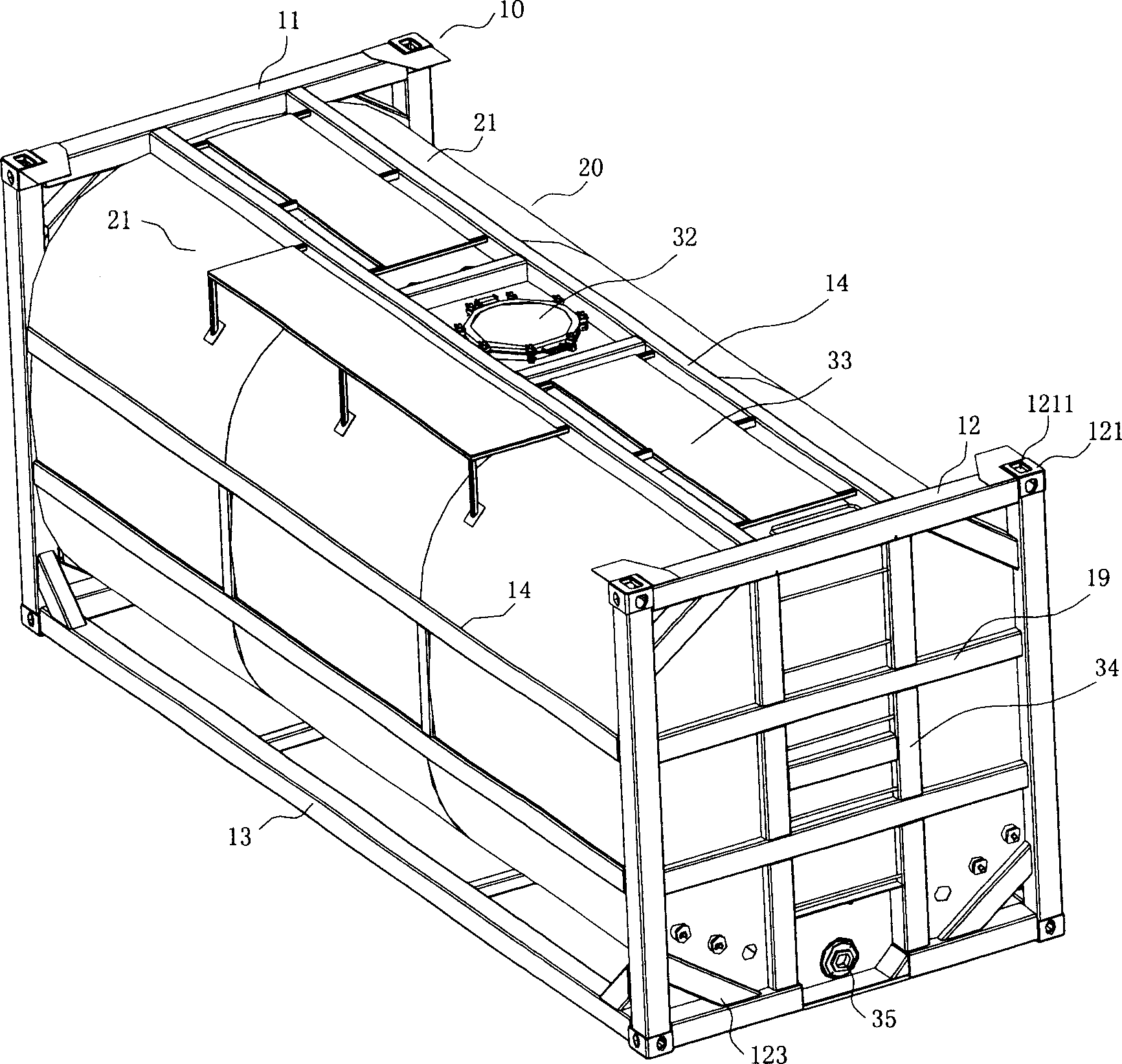

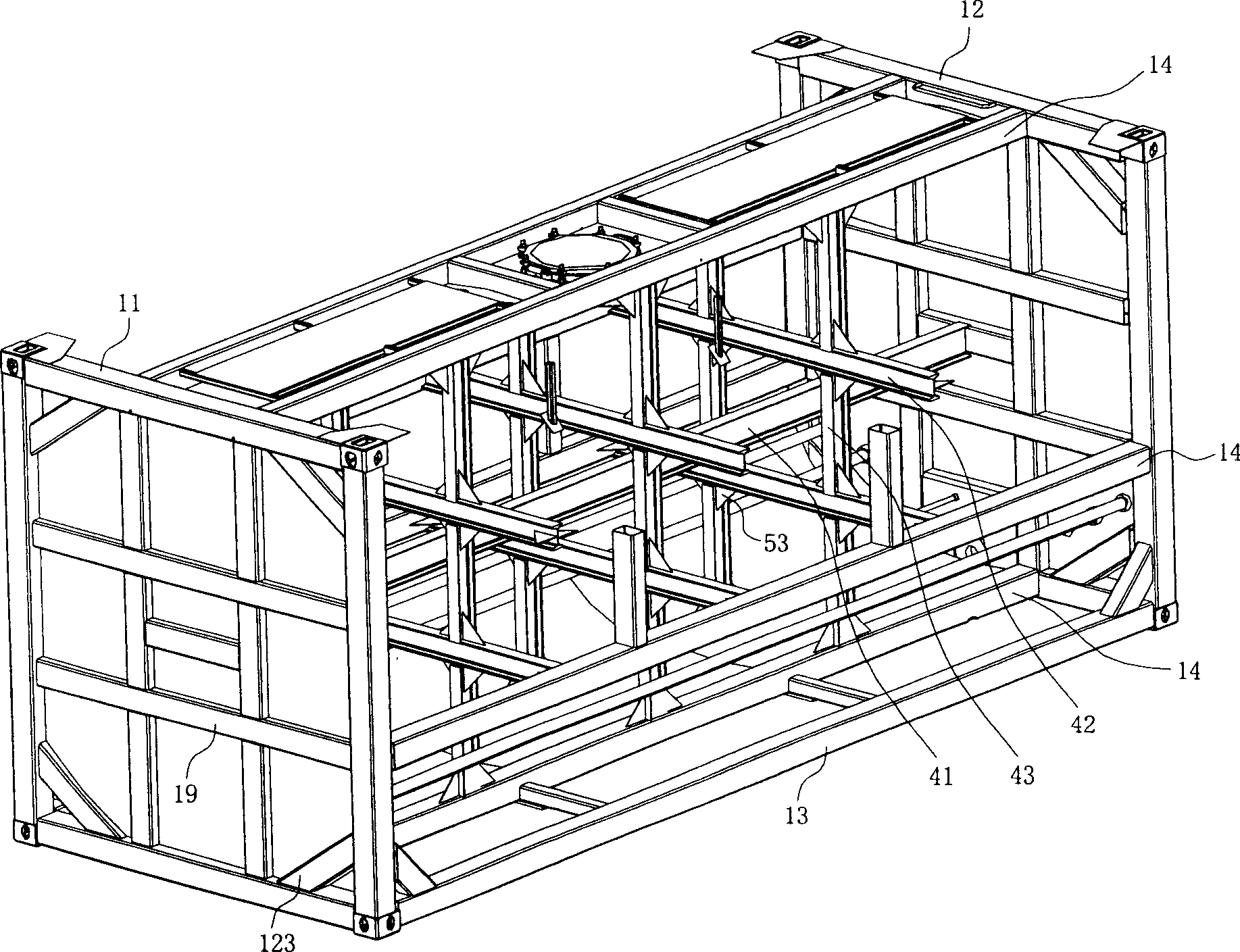

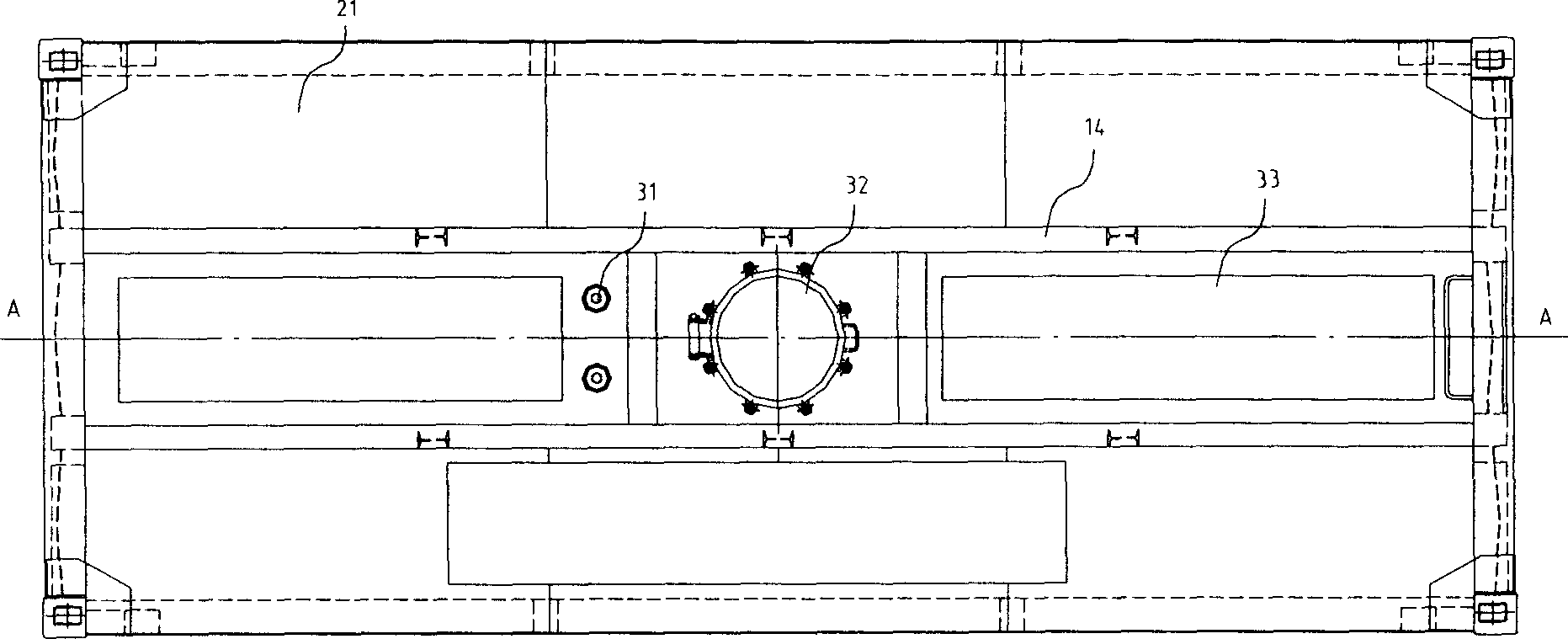

[0032] Such as figure 1 As shown, the three-dimensional structure of a tank container in a preferred embodiment of the present invention is shown. The tank container mainly includes a frame structure 10 and a tank body 20 inside the frame structure. The frame structure 10 includes: an opposite front frame 11 and a rear frame 12. The side beams 13 between the corresponding corners, in this embodiment, the side beams 13 are only arranged between the two corresponding corners at the bottom position below, of course, the side beams 13 can also be arranged on the upper Two corresponding corner positions; and longitudinal beams 14, preferably 8, distributed in the four directions of up, down, left, and right around the outside of the tank body 20, two in each direction, and each longitudinal beam The two ends of 14 are respectively connected to the frames of the front and rear end frames 11 and 12 in corresponding directions. In order to strengthen the strength of the frame struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com