Collection trolley for entire stalk type cane harvester

A technology for harvesters and collecting carts, which is applied to harvesters, loaders, agricultural machinery and implements, etc., can solve the problems of low efficiency, small volume, and restrictions on the popularization and use of whole pole sugarcane harvesters, and achieves convenience in use and excellent structure. Compactness, the effect of improving harvesting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

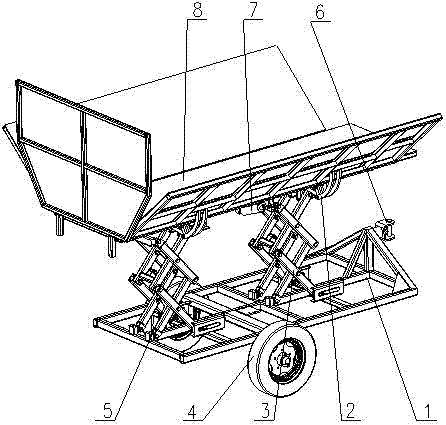

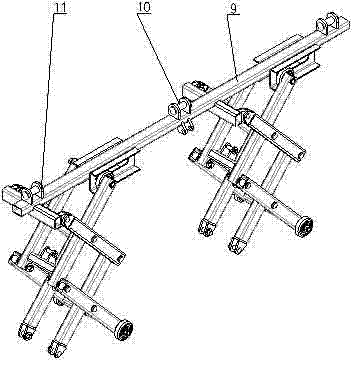

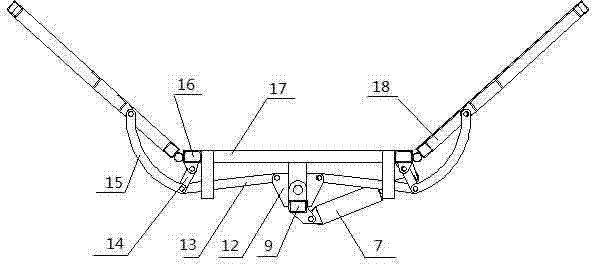

[0014] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1~3 As shown, the whole-rod sugarcane harvester collection vehicle includes: trolley chassis 1, hopper rollover device 2, hopper lifting mechanism 3, walking wheels 4, hopper lifting cylinder 5, hopper rollover cylinder 7, hopper assembly 8, Support beam 9. The dolly chassis 1 front portion that has walking wheel 4 is provided with dolly hanging interface 6, can be articulated with sugarcane harvester by hanging interface 6. The hopper lifting mechanism 3 is made up of two groups of scissor-fork lifting mechanisms, and its lifting is controlled by the hopper lifting cylinder 5 . The lower part of the hopper lifting mechanism 3 is connected with the bottom frame 1 of the trolley, and the upper part is provided with a support beam 9. 8 can be turned around around the pivot pin 10. The hopper rollover device 2 is connected between the hopper lifting mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com