Tank container for petroleum asphalt

A tank container and petroleum asphalt technology, which is applied in the field of sea, land or railway transportation of petroleum asphalt, can solve the problems of unreasonable frame structure, small loading capacity and low safety performance, and achieve reasonable frame structure design and high loading capacity. Large, the effect of saving transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

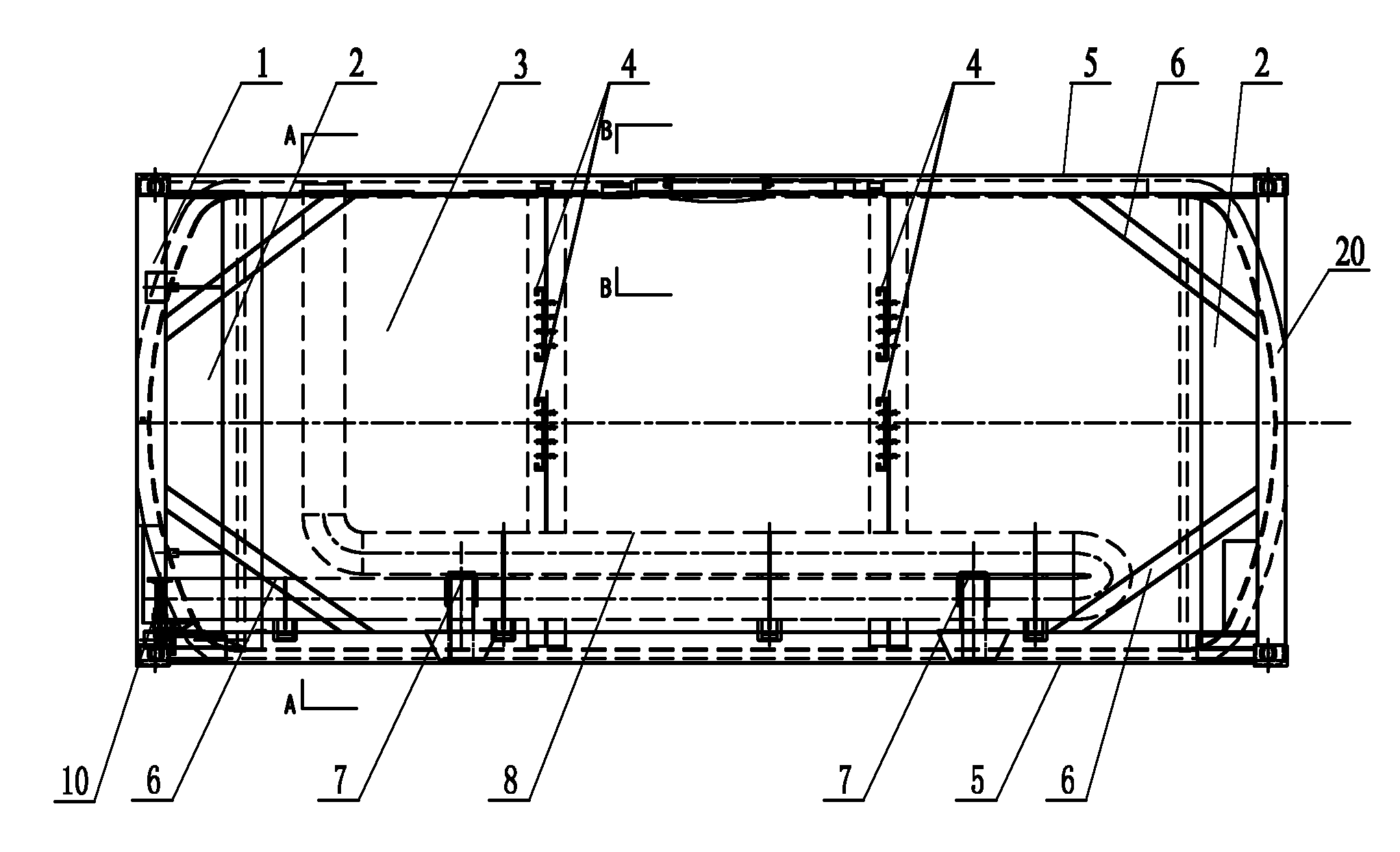

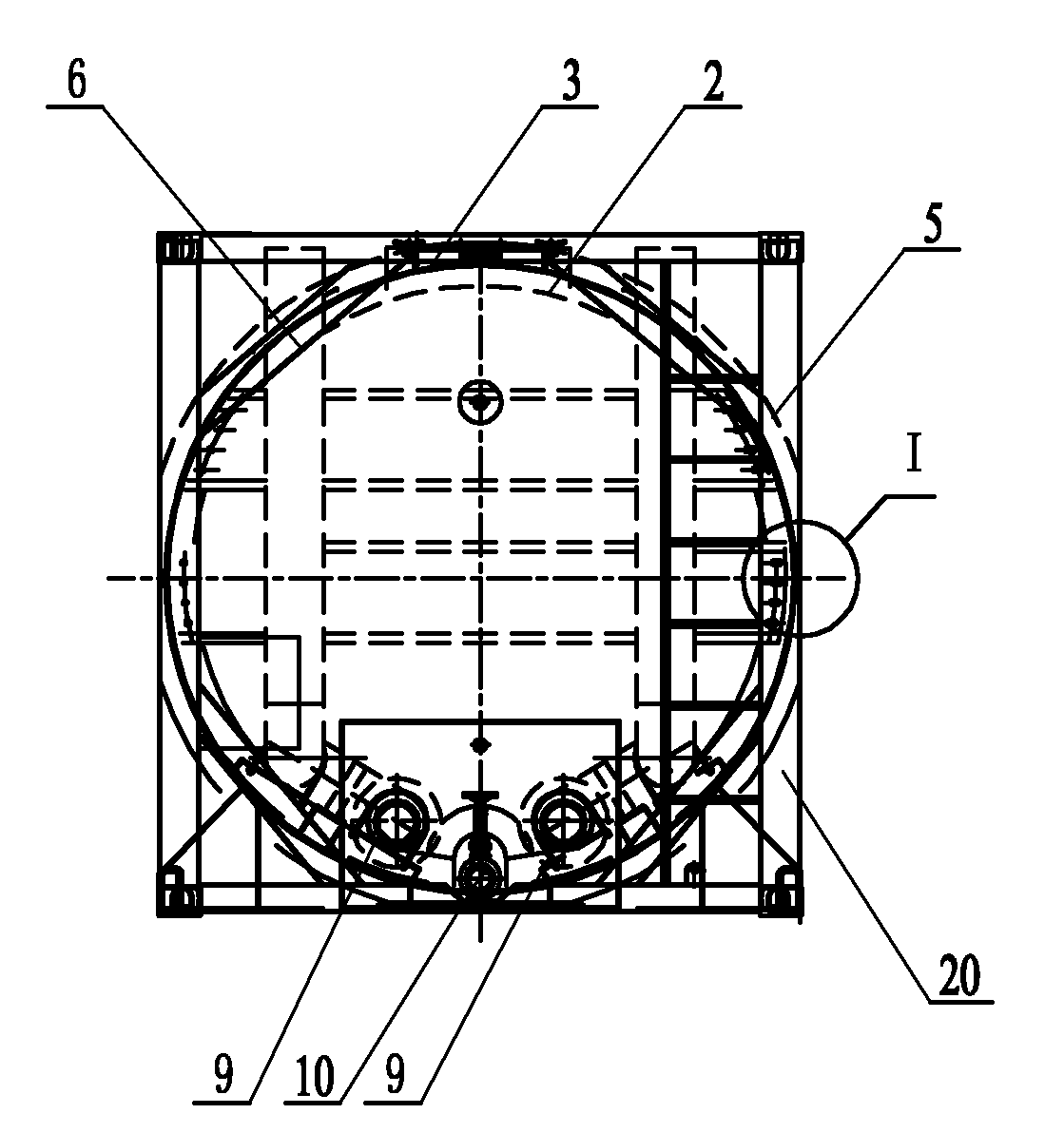

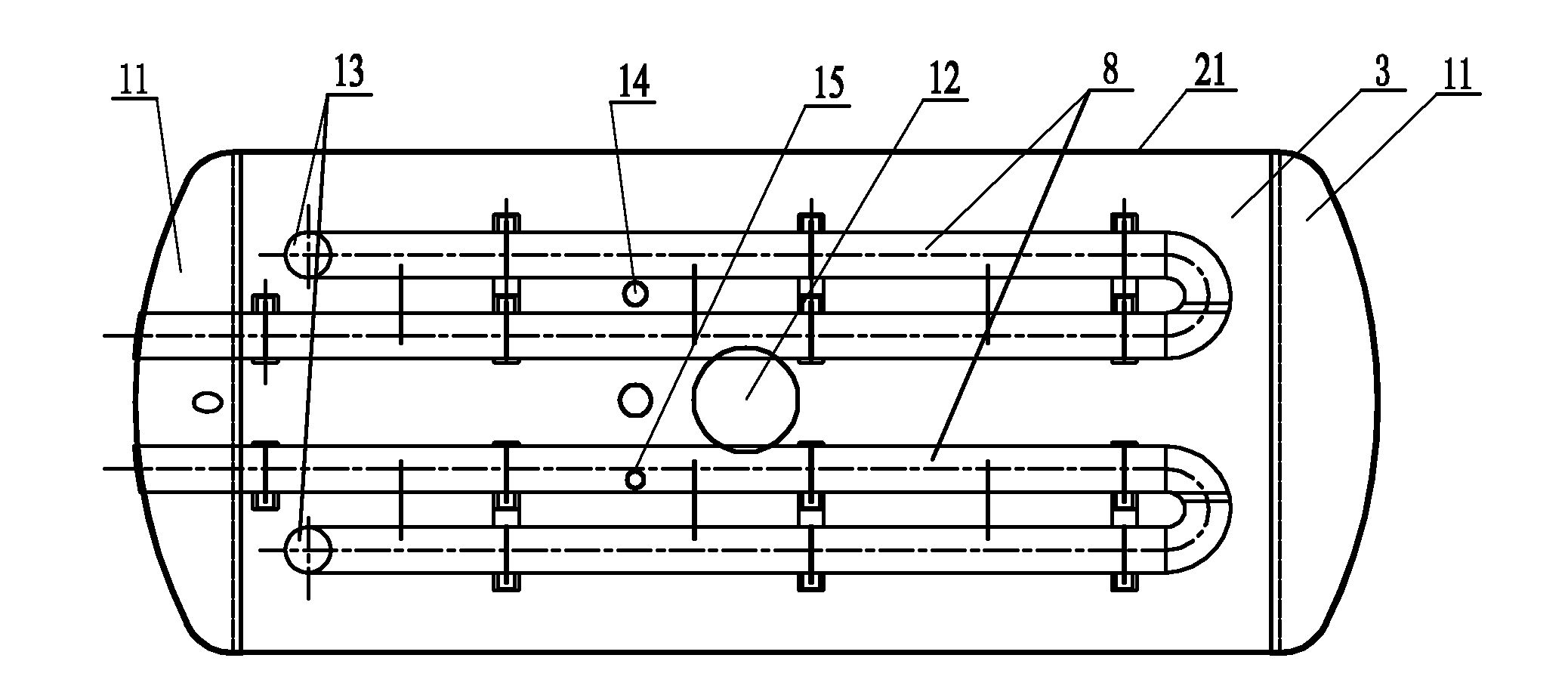

[0008] Specific implementation mode one: combine Figure 1-Figure 5 , Figure 7 with Figure 8 Describe this embodiment, the petroleum asphalt tank type container of this embodiment comprises frame 1, tank body 3, decompression valve 14, one-way valve 15, unloading valve 10, two end cylinders 2, two support saddles 7, Four anti-wave plates 4, two heating pipes 8 and two flues 13; the frame 1 includes two end frames 20 and four longitudinal beams 5, and four longitudinal beams 5 pass between the two end frames 20 Fixedly connected together, the two ends of the tank body 3 are fixedly connected to the frame 1 through an end cylinder 2, the bottom surface of the tank body 3 is fixedly connected to the frame 1 through two supporting saddles 7, and the top of the tank body 3 is provided with a human body. Hole 12, pressure reducing valve 14 and one-way valve 15, the inside of the tank body 3 is provided with two anti-wave devices along its longitudinal direction, each anti-wave d...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination Figure 9 Describe this embodiment, each end frame 20 of this embodiment is made up of two beams 22, two columns 23 and four corner pieces 24, and the two beams 22 and two columns 23 are arranged to form a frame, and the beams 22 It is fixedly connected with the column 23 through the corner piece 24. Such setting forms a rigid structure, and the structure is more reasonable. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination figure 1 , figure 2 , Figure 8 with Figure 9 To illustrate this embodiment, the frame 1 of this embodiment also includes twenty-four support ribs 6, three support ribs 6 are fixedly installed at each corner of the frame 1, and the three support ribs 6 at the same corner form a triangle . Such setting is used to strengthen the load-bearing capacity of the frame. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com