Bottle, bottle cap and detector for detecting airtightness of sealed pot

A sealing and testing instrument technology, which can be used in liquid/vacuum measurement for liquid tightness, measurement of fluid acceleration and deceleration rates, and application of stable tension/pressure to test material strength, etc., which can solve the detection of sealing There is no good detection method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

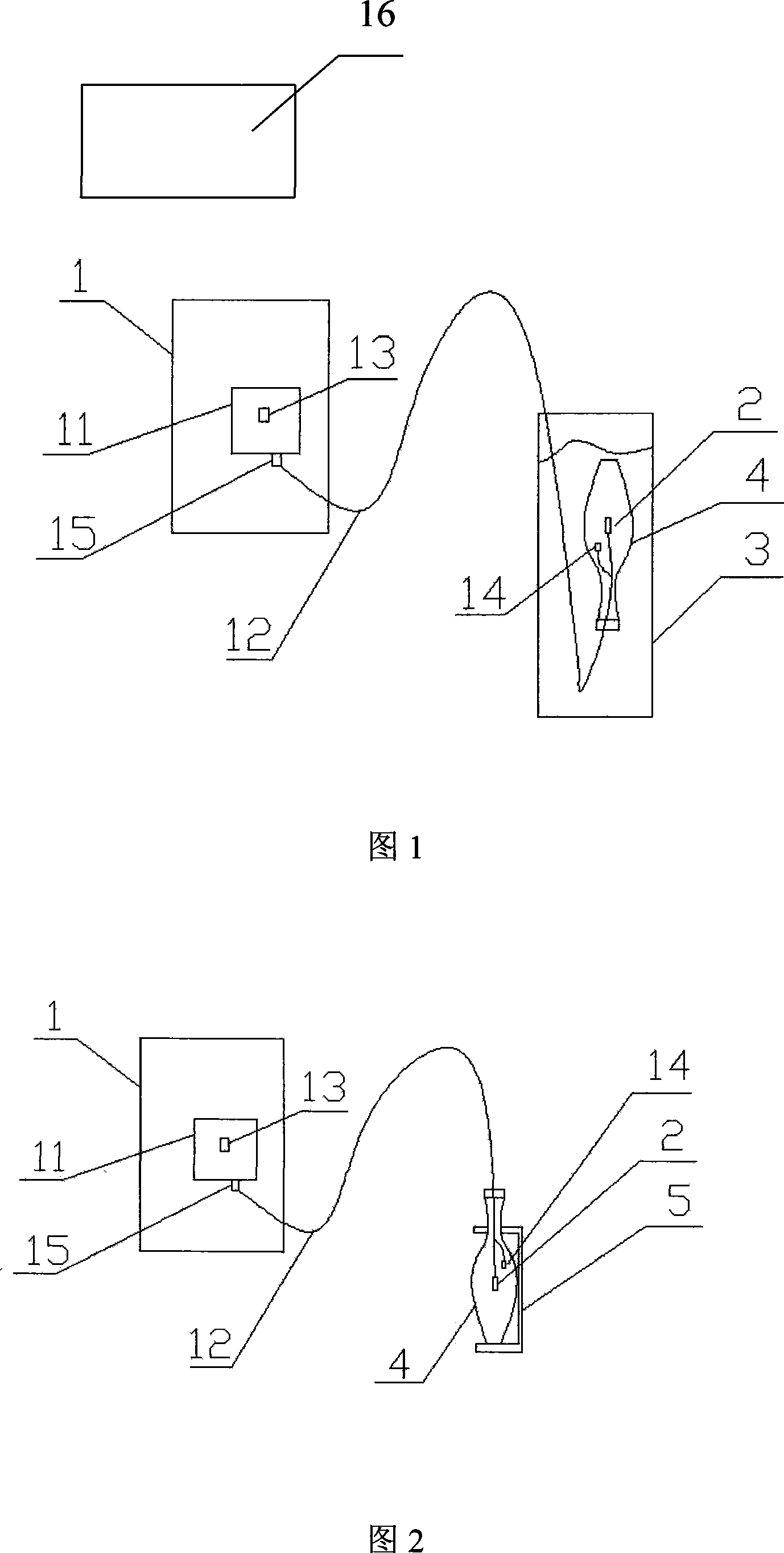

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] The preferred embodiment of the present invention is shown in FIG. 1 , which includes a host 1 , a test head 2 and a test water tank 3 . The host machine 1 is provided with a pressure control device 11 inside, and the pressure control device 11 is connected to the test head 2 through a gas pipeline 12 . A controllable solenoid valve 15 is arranged between the pressure sensor 11 and the gas pipeline 12 to control the communication / closing between the pressure sensor 11 and the gas pipeline 12, and the entire experimental process is controlled by a PLC liquid crystal display programmable controller 16 and display.

[0016] When carrying out the sealing test, as shown in Figure 1, fill the test water tank 3 with water, open a small hole with a diameter of 2-3mm on the top of the container 4, and insert the test head 2 into the preform 4 through the small hole, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com