Patents

Literature

38results about How to "Improve transport safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

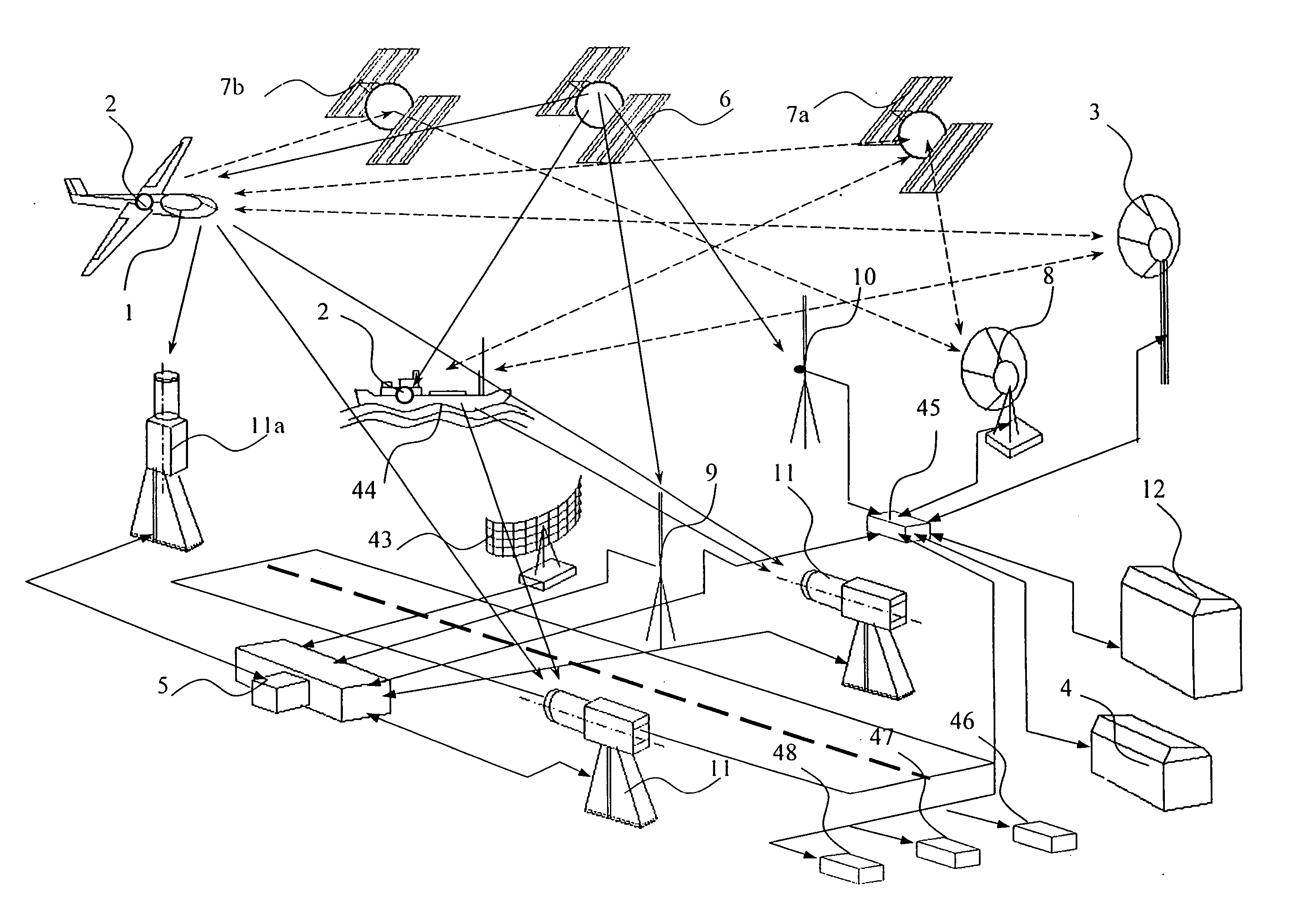

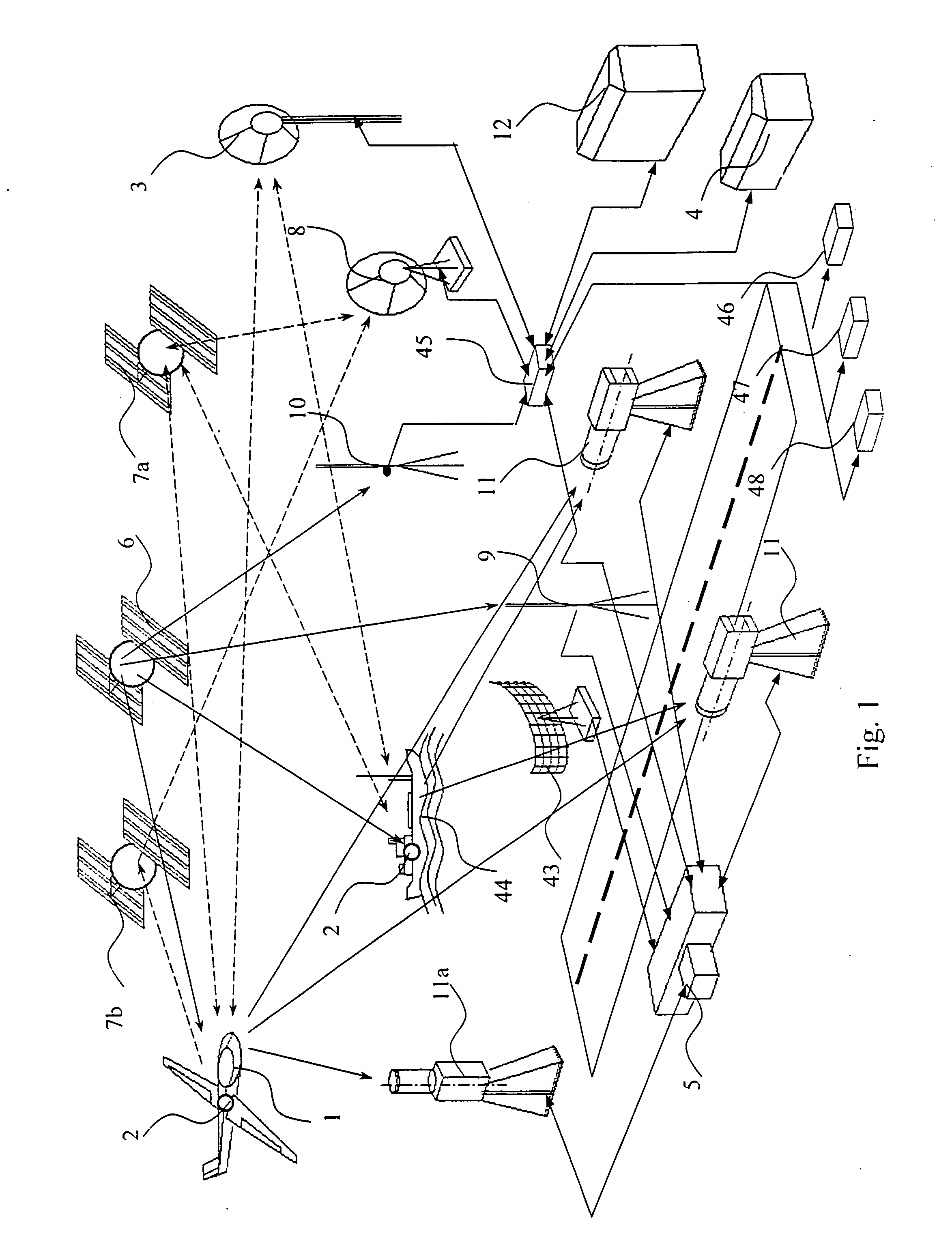

Control and communication system and method

InactiveUS20050090978A1Satisfies requirementEnhanced informationInstruments for road network navigationDigital data processing detailsCommunications systemLibrary science

The invention relates to a control and communication system and method for objects, the system comprising an object space-information database in an object centre of the object, the database storing an object plan for the object, wherein the control of the object is adjusted to the object plan, a regional control centre having a regional space-information database storing a regional plan, and a main control centre having a central space-information database storing a central plan. The central plan approved by the regional control centres is prepared by the main control centre, the regional plans are updated at the regional control centres on the basis of the central plan, and the object plans are updated at the object centres on the basis of the regional plans.

Owner:RDS X FEJLESZTESI & TANACSADO

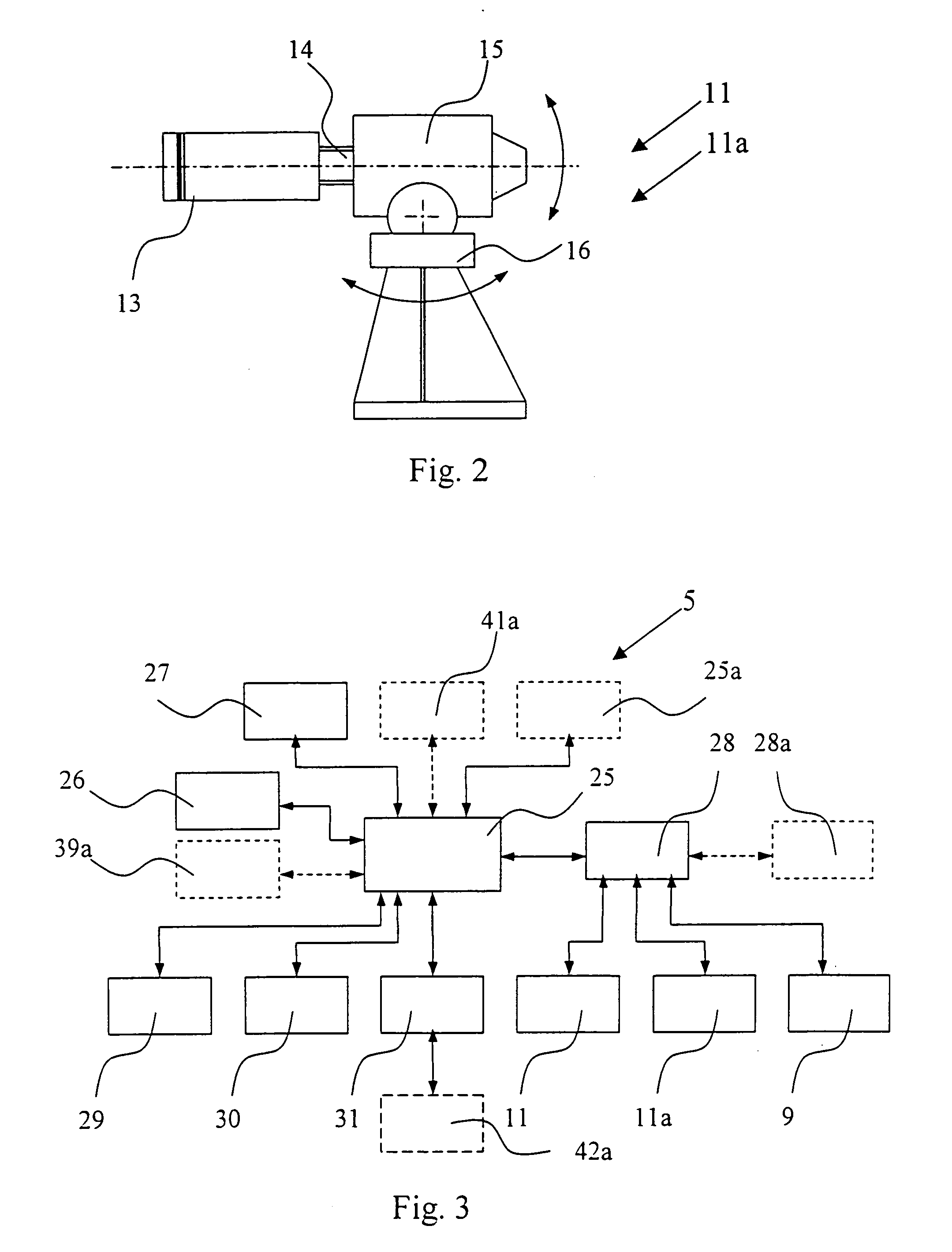

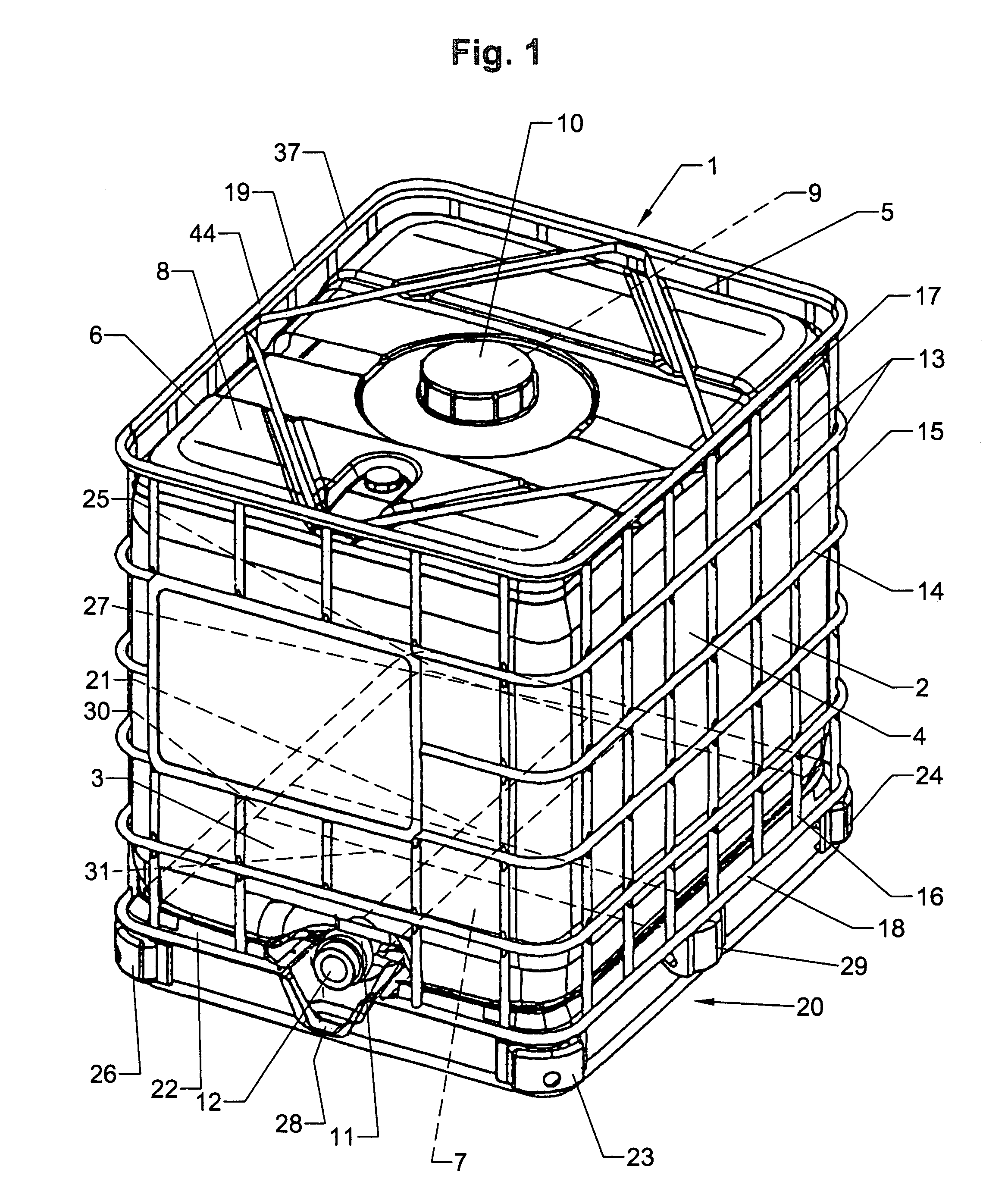

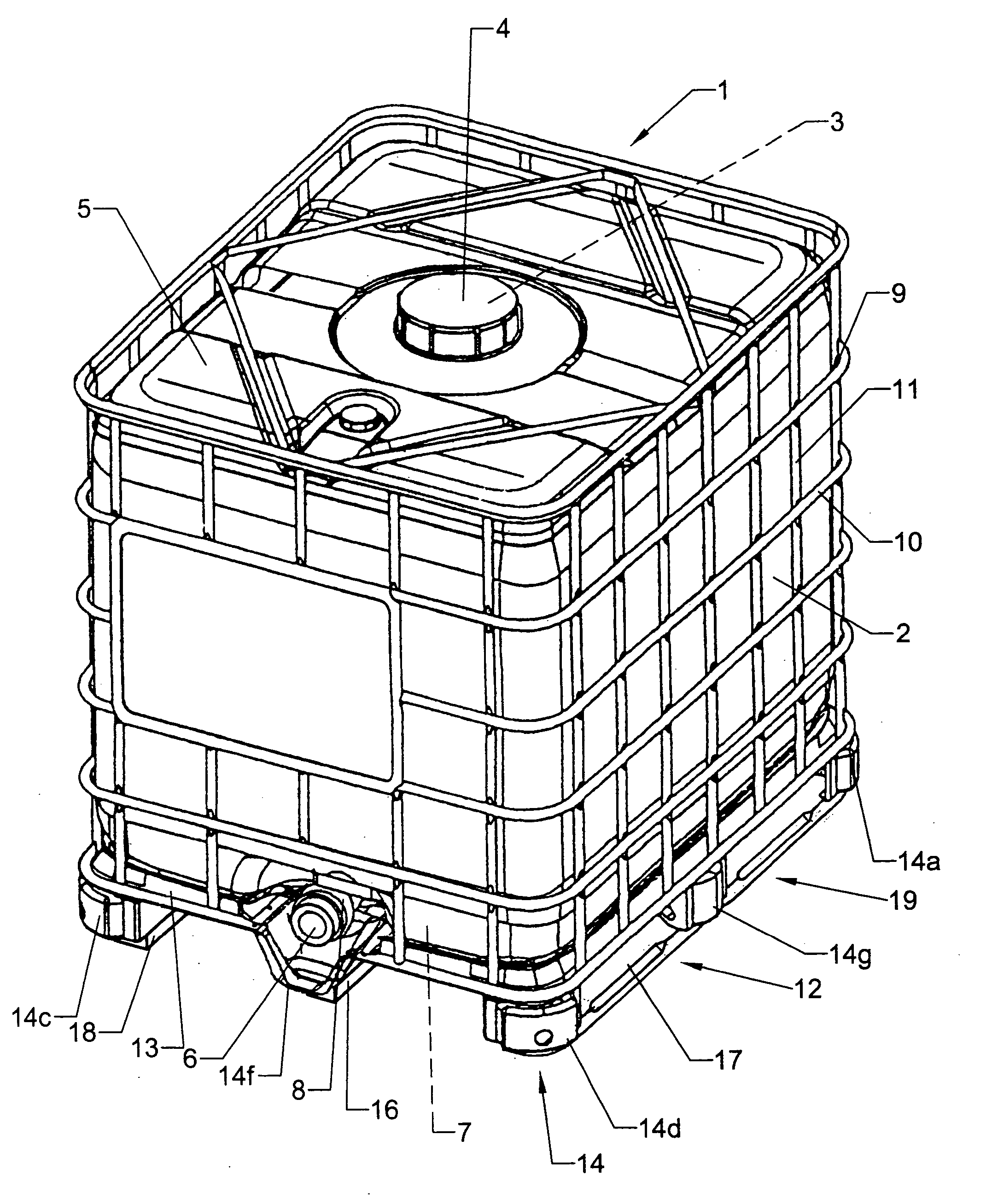

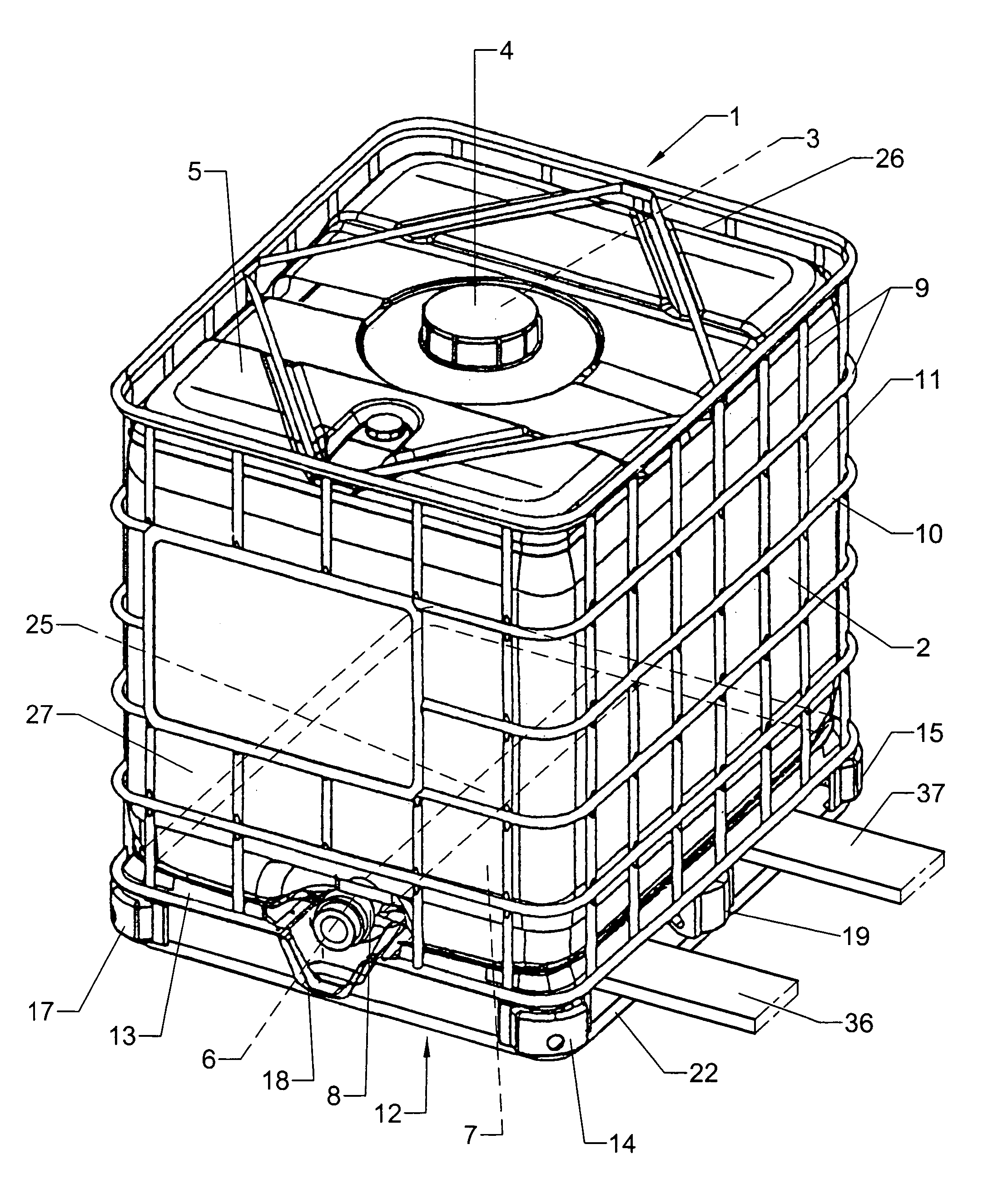

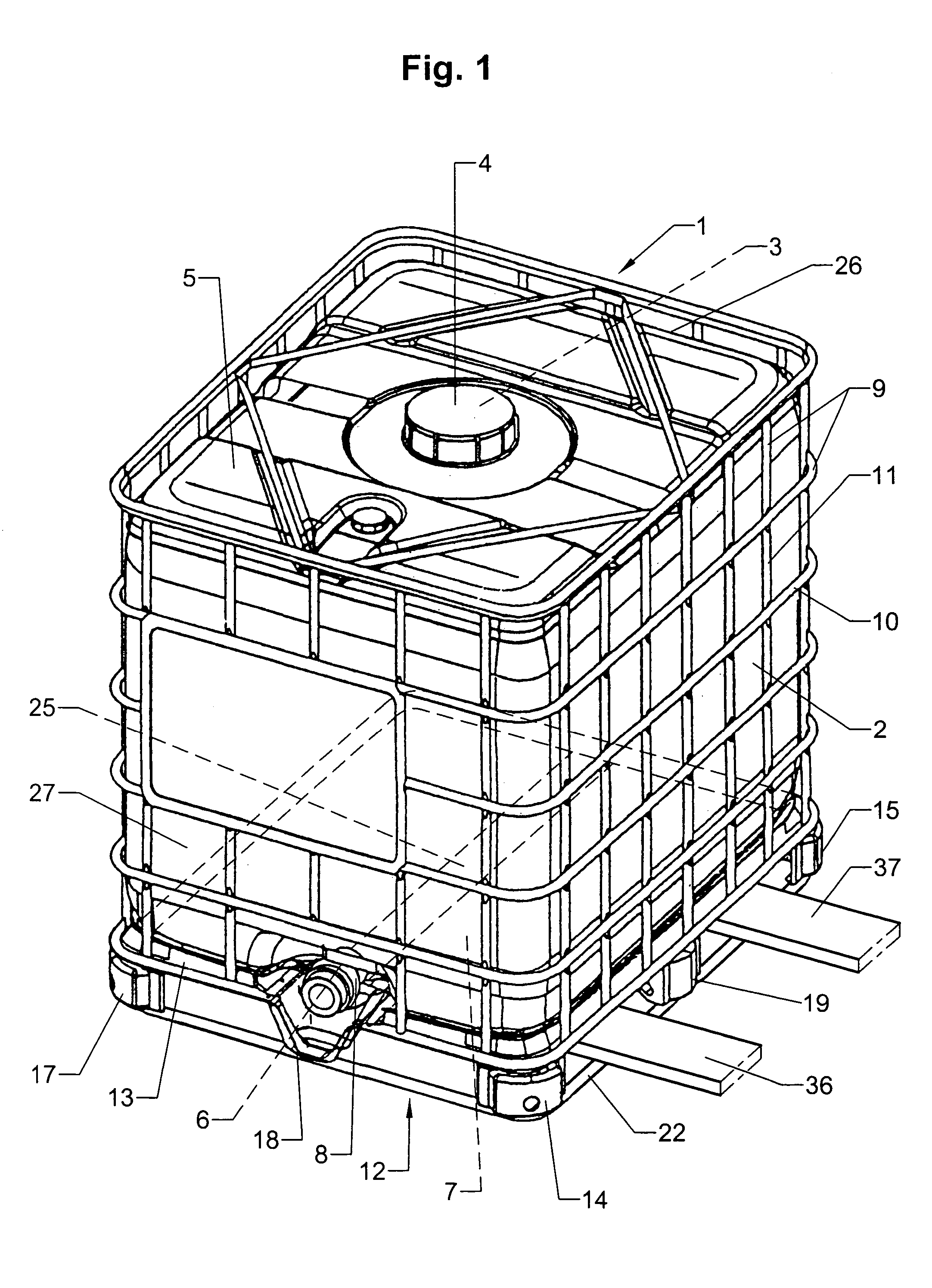

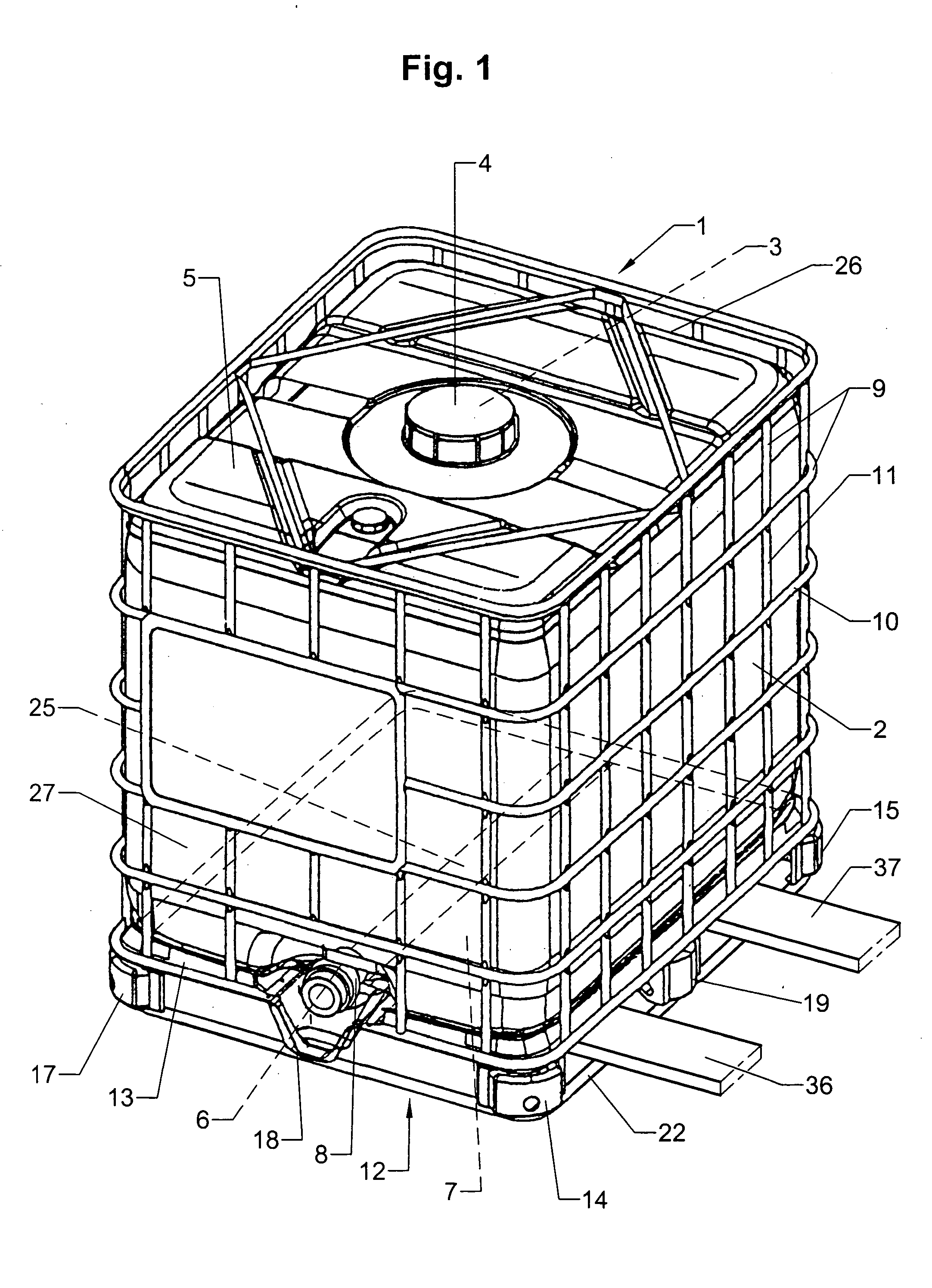

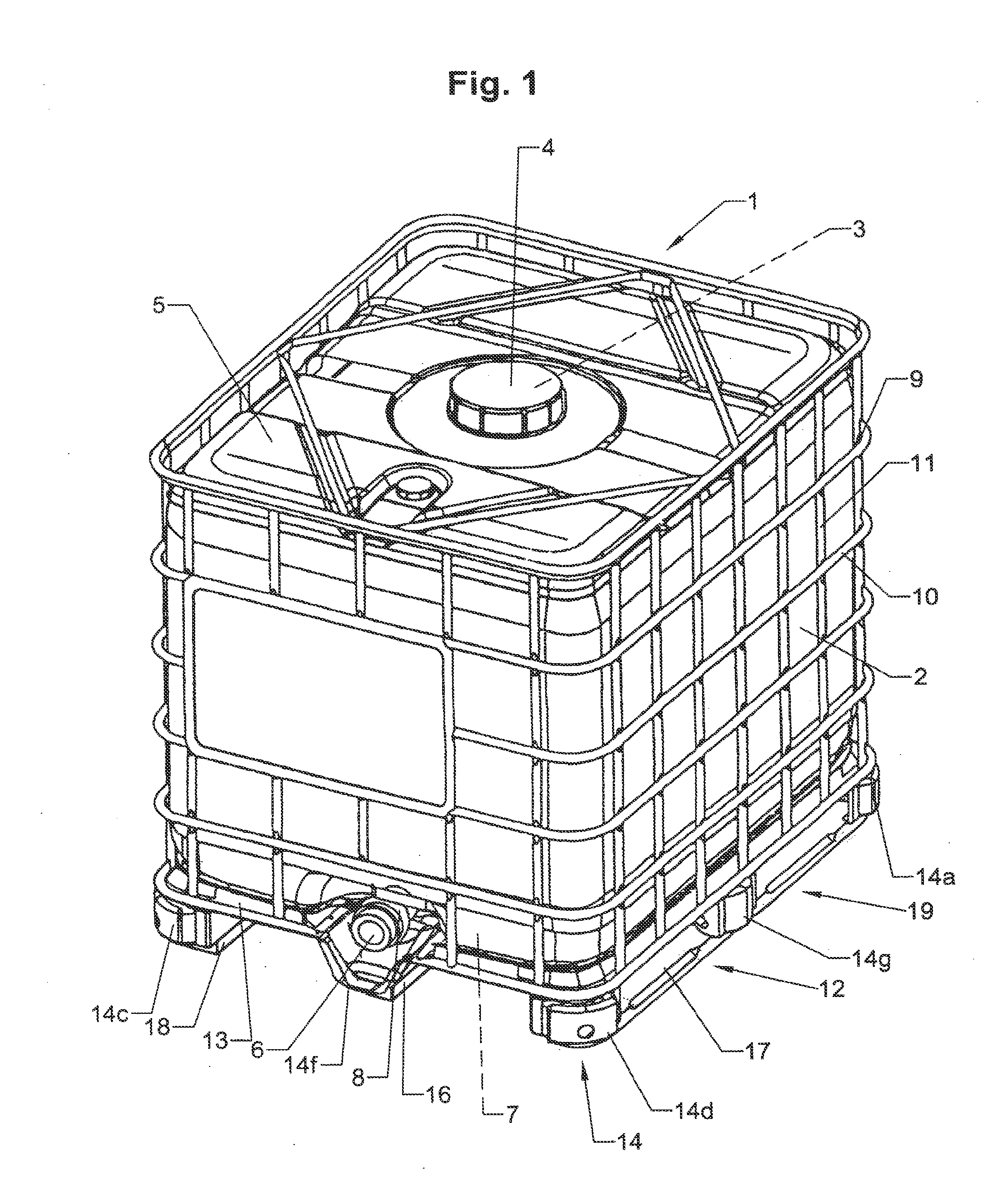

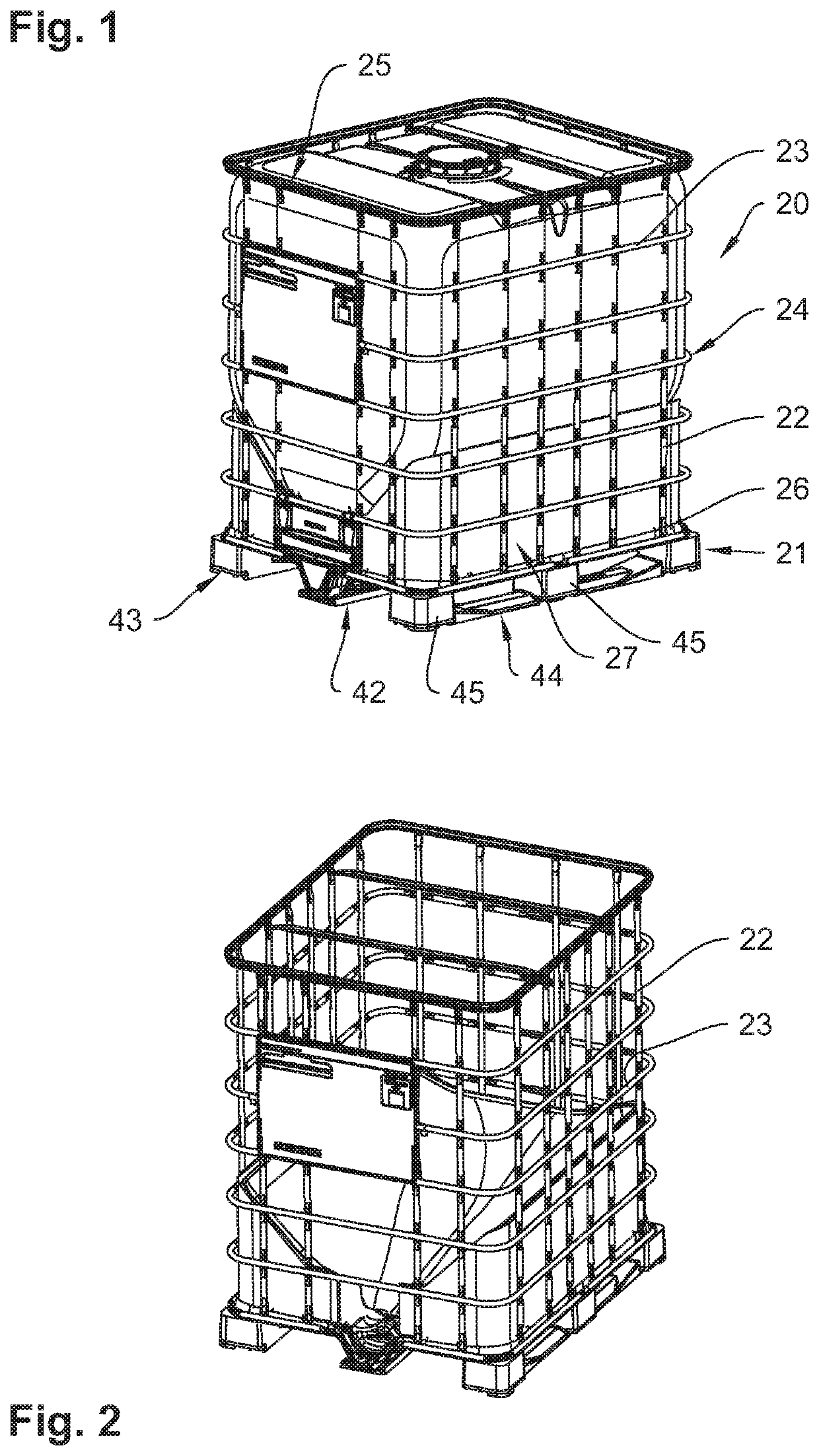

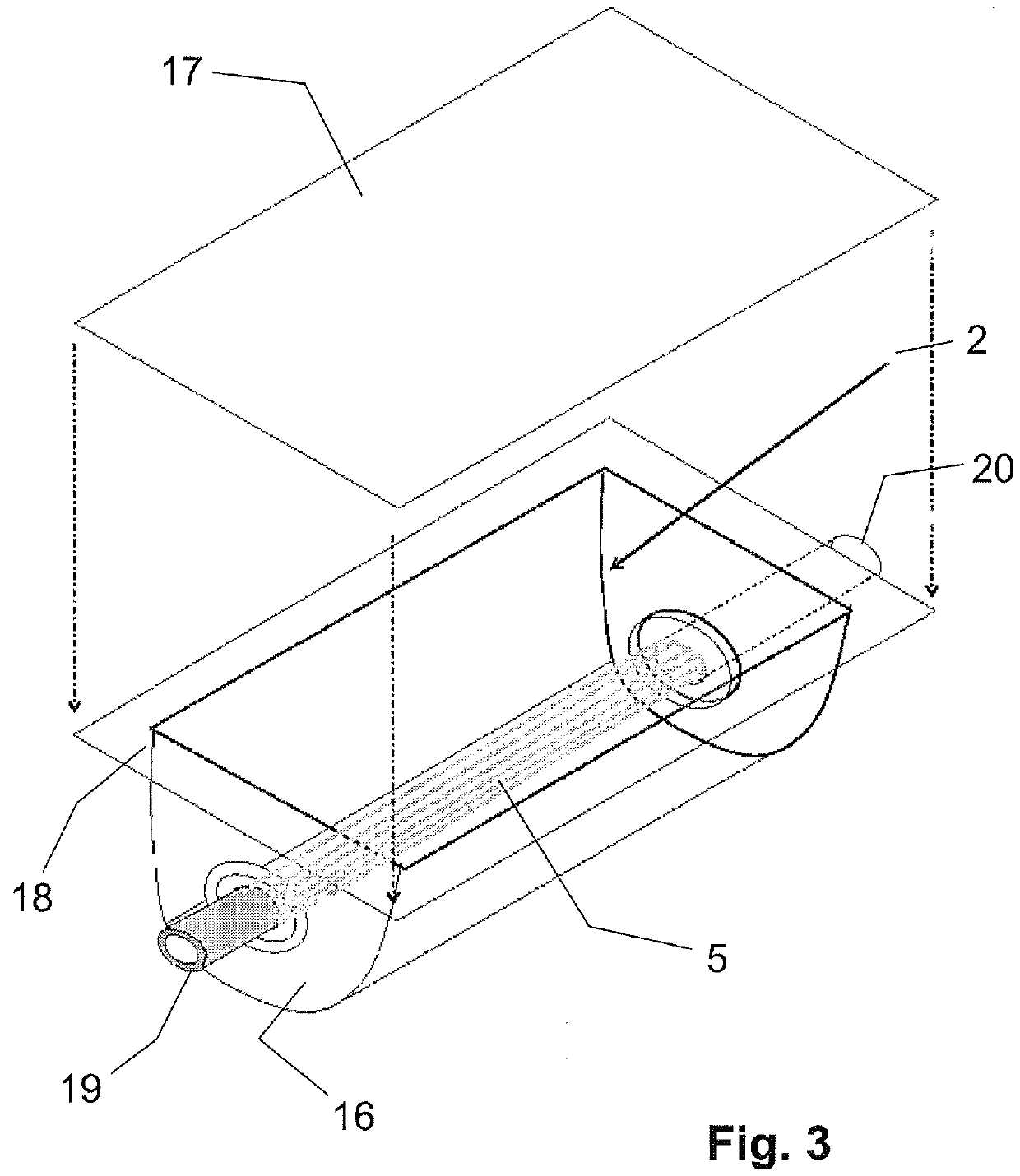

Transport and storage container for liquids

ActiveUS7036662B2Avoid damagePrevent disengagementLarge containersOther accessoriesEngineeringLatticework

A transport and storage container for liquids has a pallet bottom frame, a latticework enclosure connected to the bottom frame, and an inner container received in the enclosure. The vertical rods of the latticework enclosure are connected to upper and lower peripheral profiled edge sections. The vertical rods are hollow and have flattened upper ends shaped to a wave profile with welding projections. The upper profiled edge section is a hollow profiled section formed to a double bar that extends peripherally and transversely to the vertical rods and is shaped to have inner and outer wave profiles engaging one another. The outer wave profile has grooves, and the inner wave profile forms welding projections. The upper ends of the vertical rods and the double bar are connected by projection welding. The upper profiled edge section has a flat upper rim for supporting legs of a container stacked on top.

Owner:PROTECHNA SA

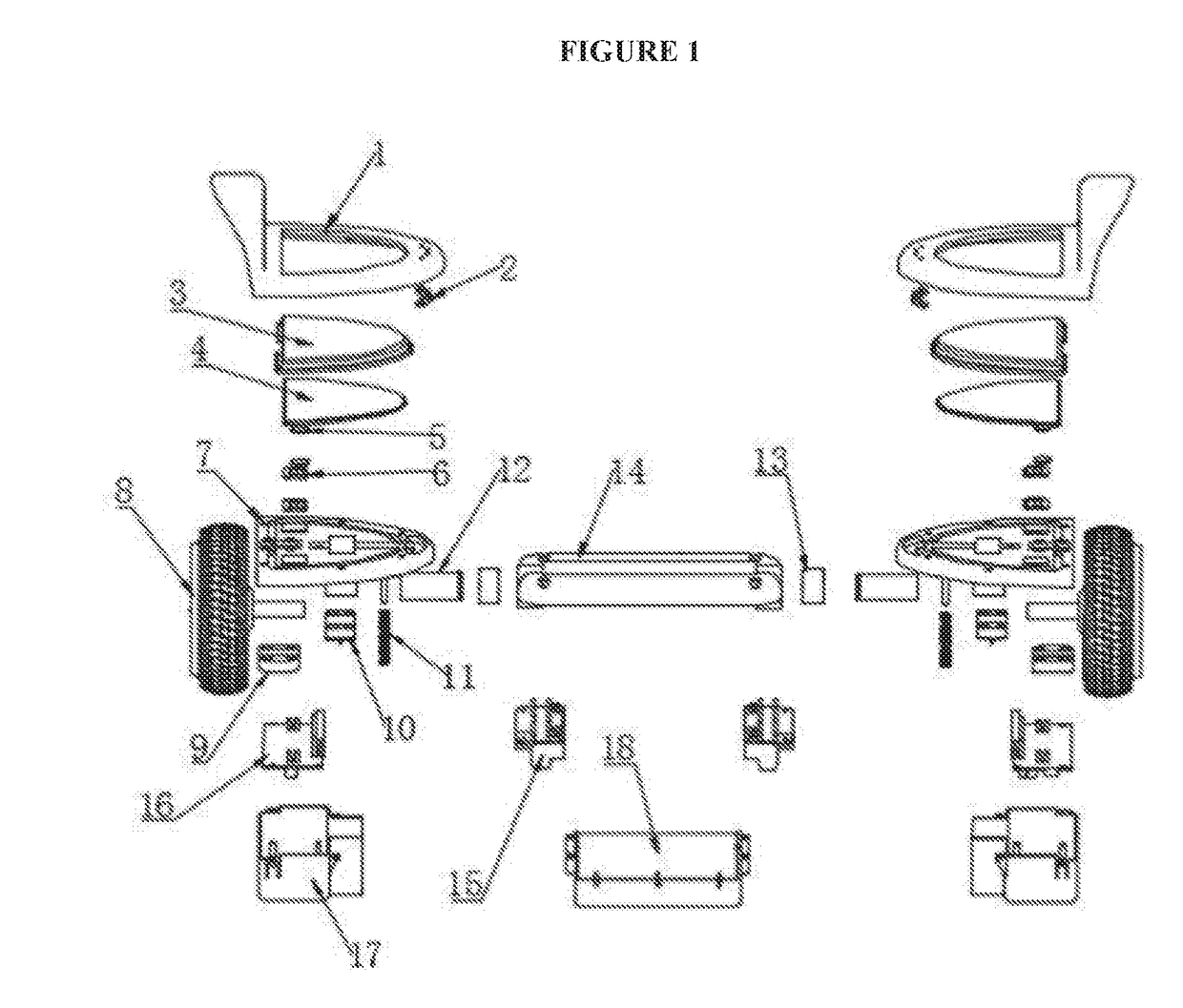

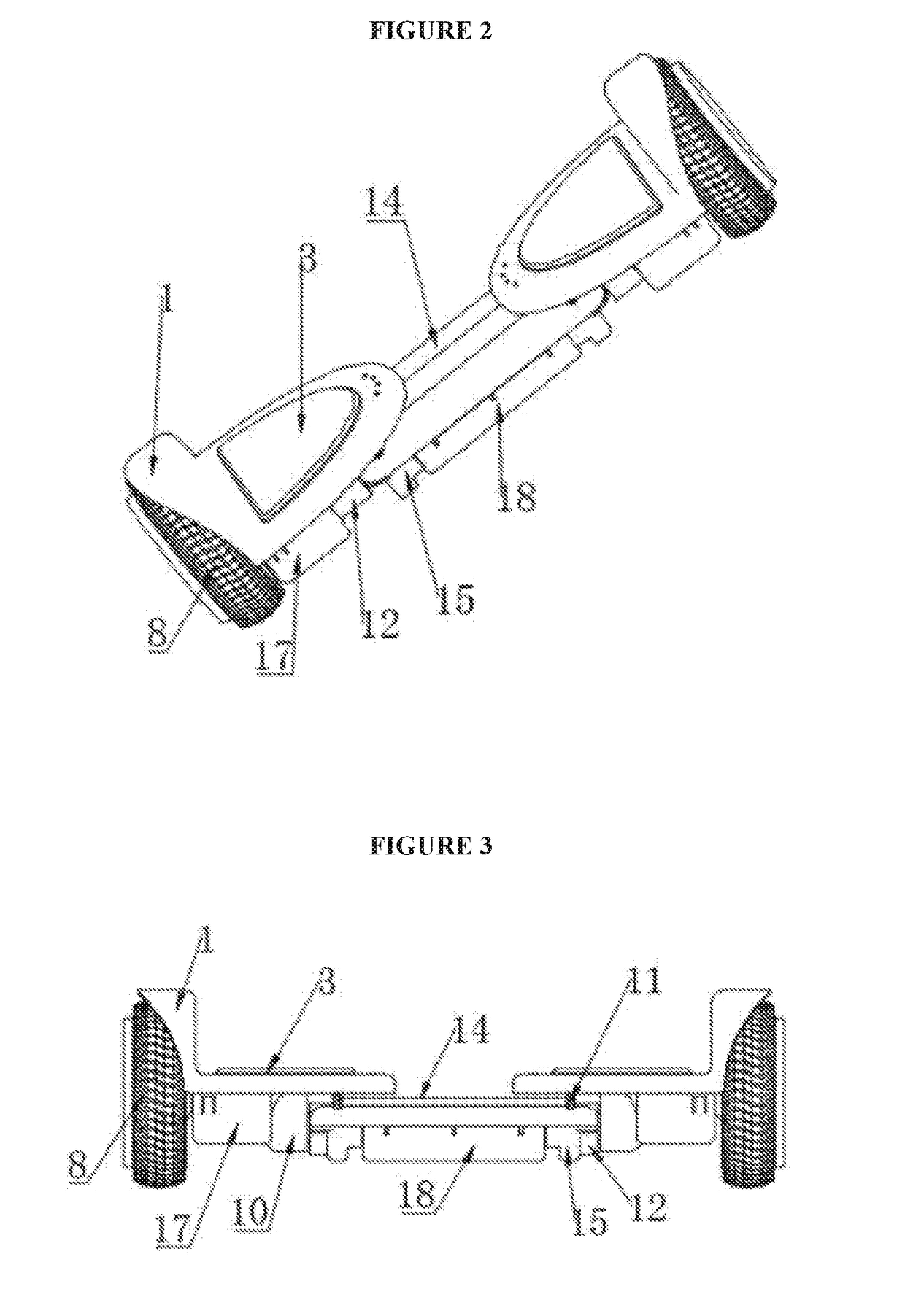

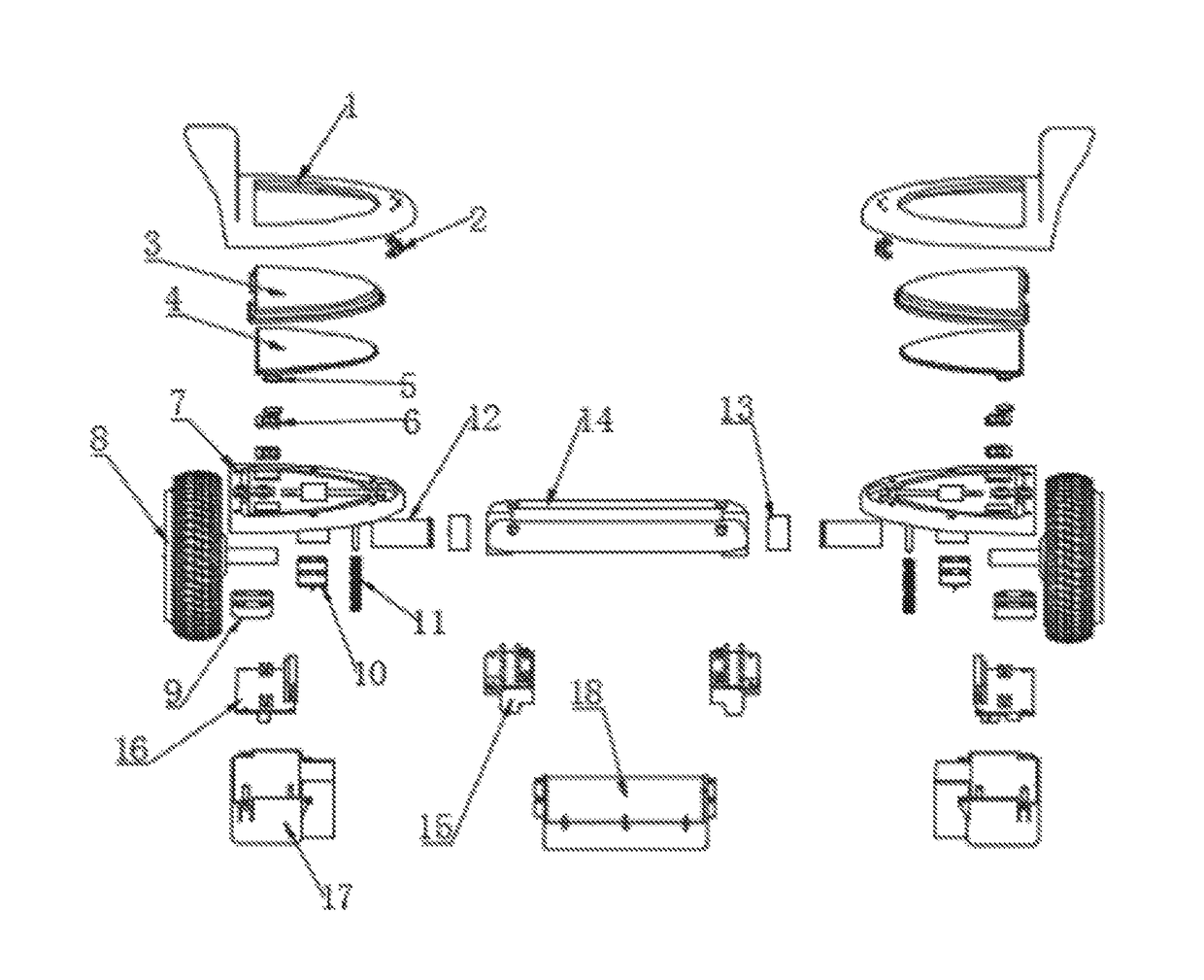

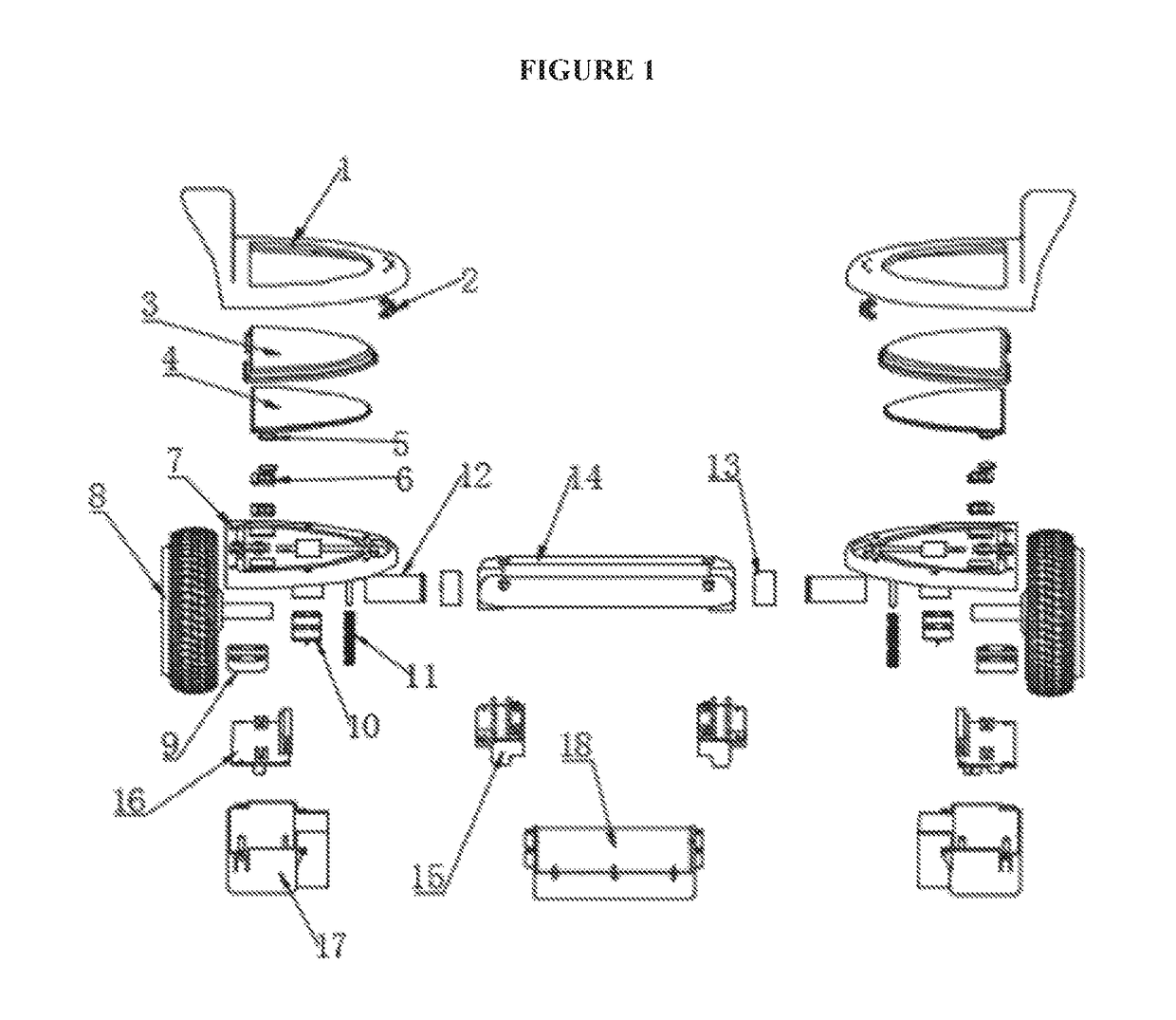

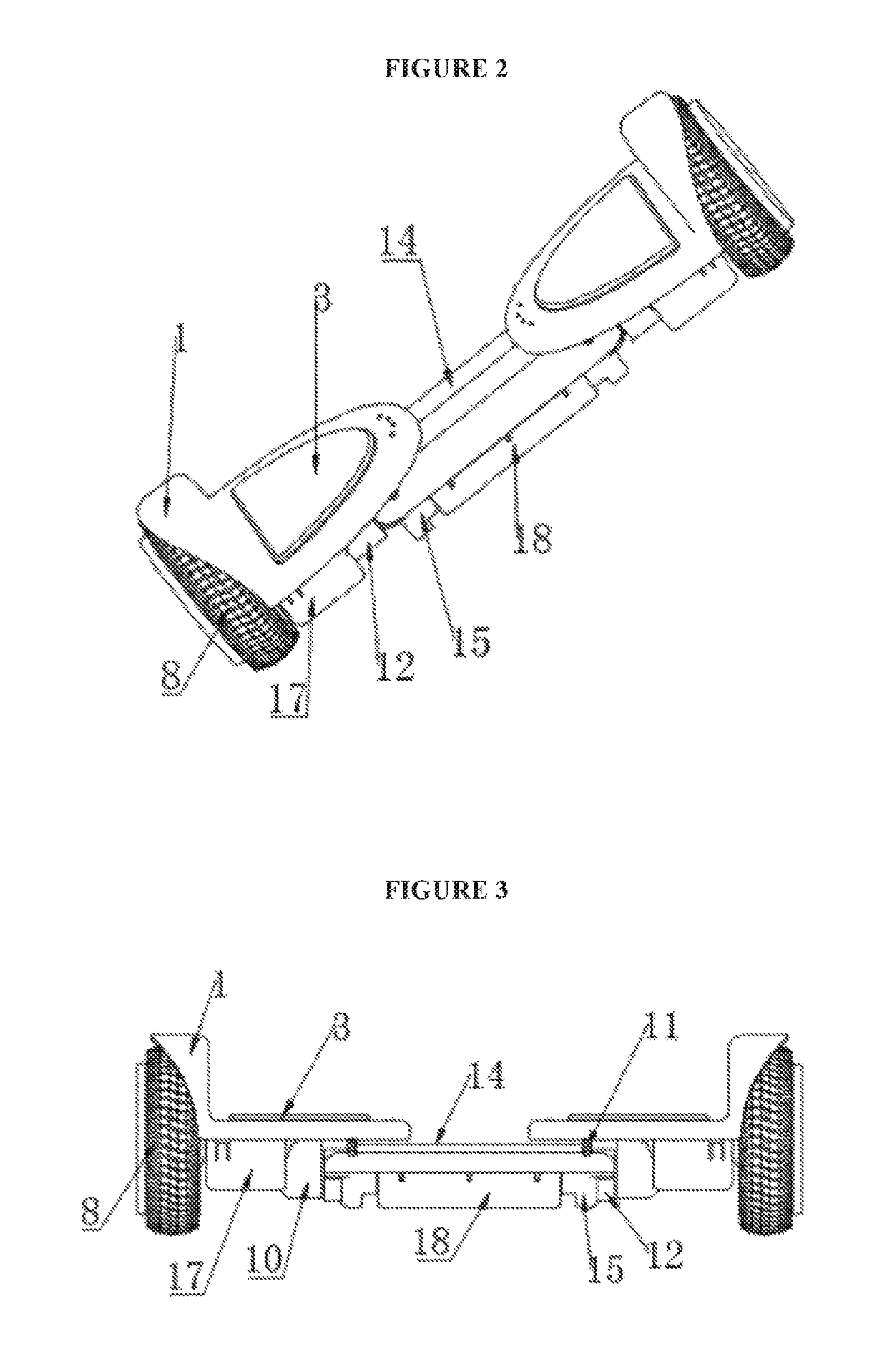

Two-axle vehicle balance scooter

ActiveUS20170166278A1Reasonable designImprove protectionAcoustic signalOptical signalAxial compressionEngineering

The two-axle vehicle balance scooter includes an upper shell, lower shell, pedal, pressure sensors, brackets, wheels, press block, shaft, chip, and battery pack. The brackets include a pedal bracket, hardware support, battery support and chip support. The press block includes a wheel pressure block and an axial compression block, from bottom to top on the housing gasket installed the pedal bracket and pedals. Both sides of the body are disposed around a middle section that is a battery holder below which a battery is installed. Accordingly, the scooter is symmetrical thus providing better stability, easier handling, easy installation and removal of a battery and other benefits.

Owner:SULTAN MASUD

Two-axle vehicle balance scooter

ActiveUS9896146B2Reasonable designImprove protectionAcoustic signalOptical signalAxial compressionEngineering

The two-axle vehicle balance scooter includes an upper shell, lower shell, pedal, pressure sensors, brackets, wheels, press block, shaft, chip, and battery pack. The brackets include a pedal bracket, hardware support, battery support and chip support. The press block includes a wheel pressure block and an axial compression block, from bottom to top on the housing gasket installed the pedal bracket and pedals. Both sides of the body are disposed around a middle section that is a battery holder below which a battery is installed. Accordingly, the scooter is symmetrical thus providing better stability, easier handling, easy installation and removal of a battery and other benefits.

Owner:SULTAN MASUD

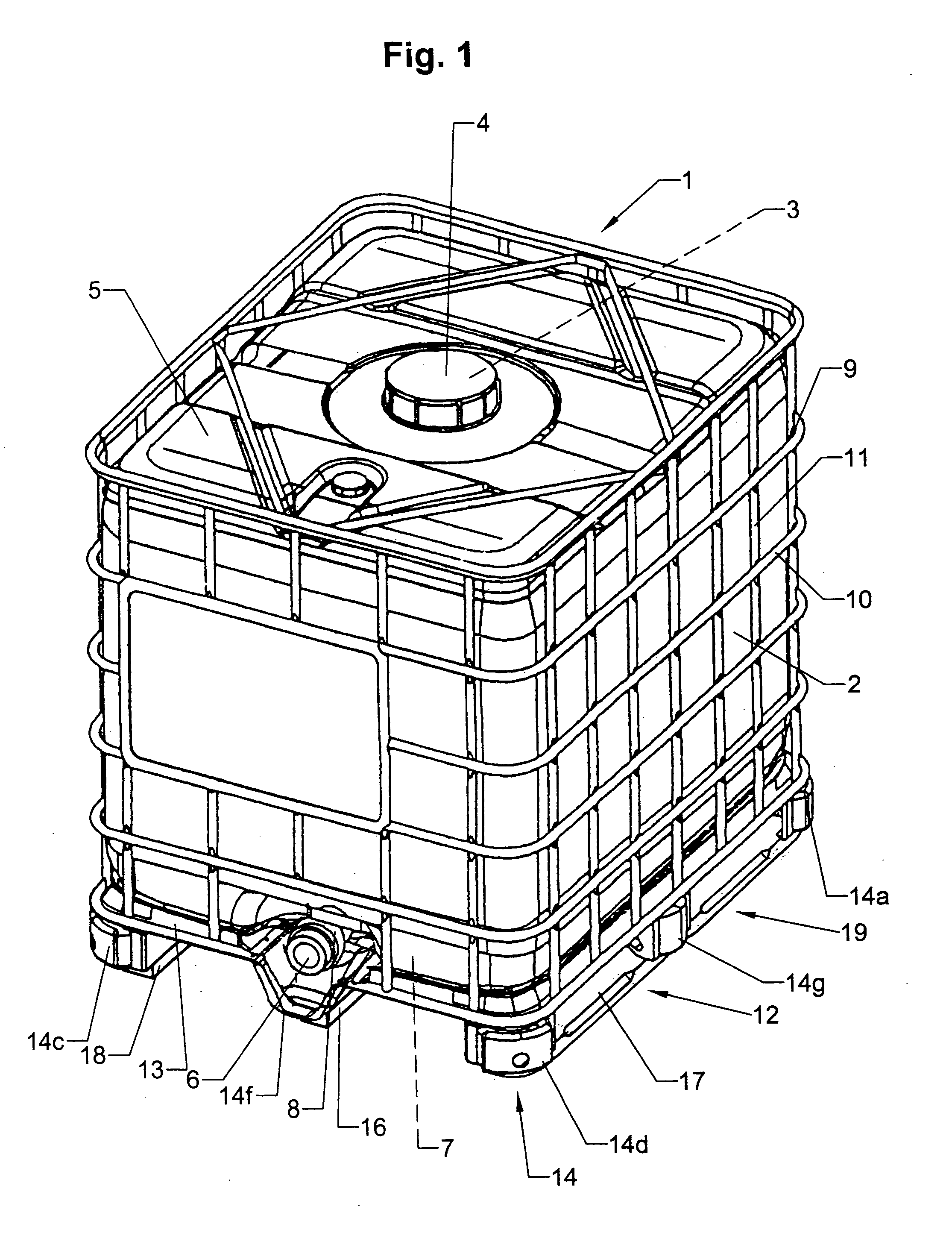

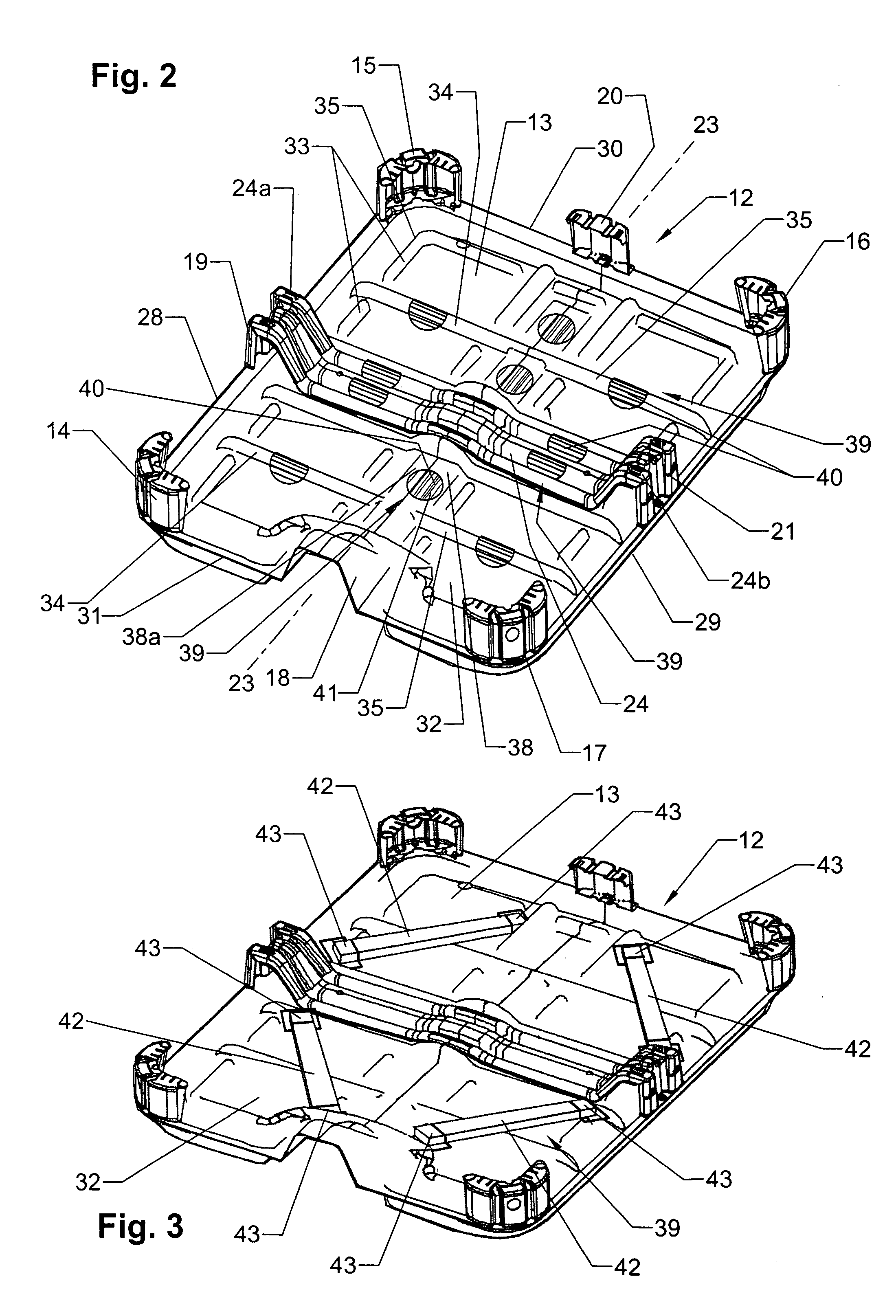

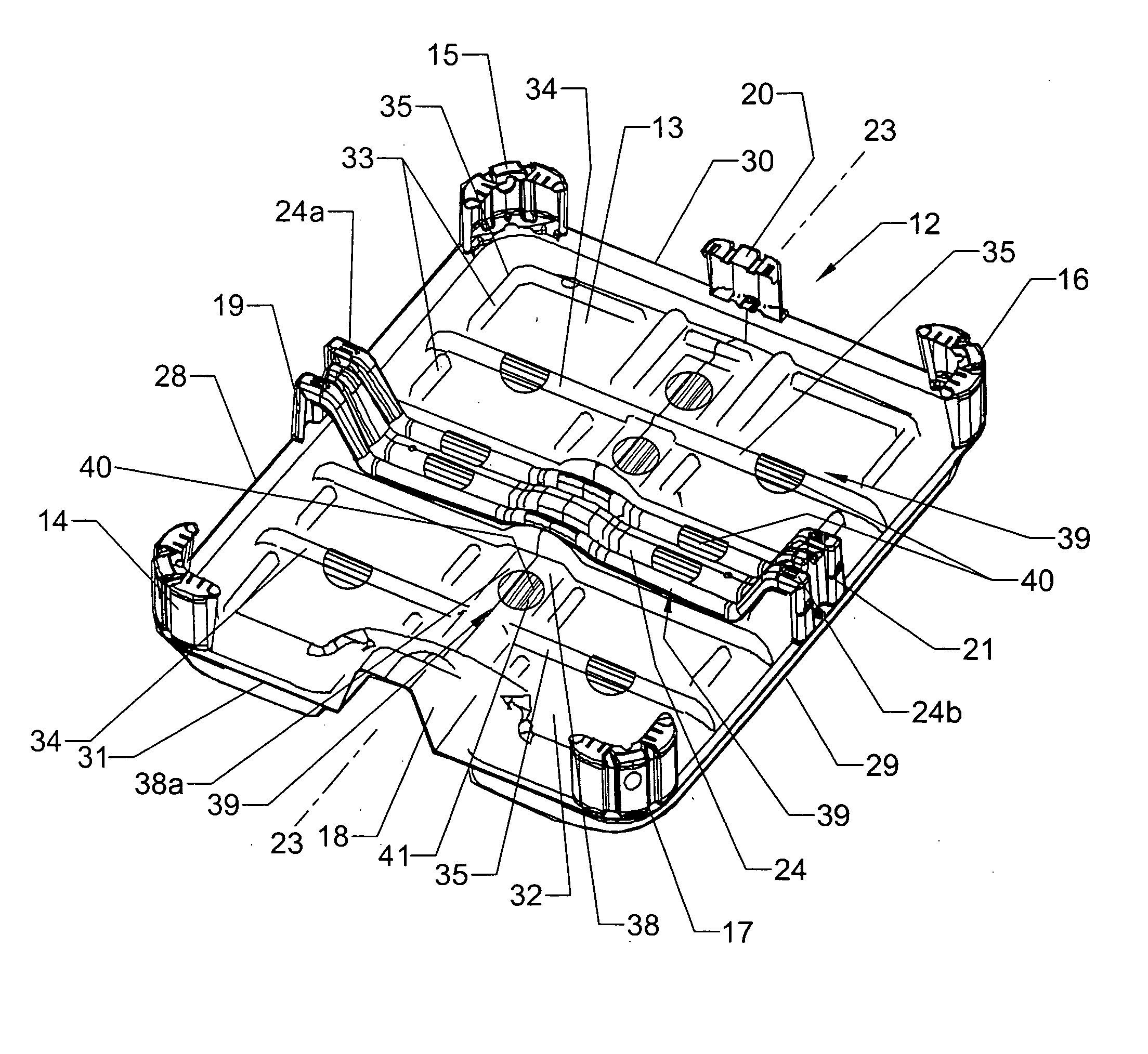

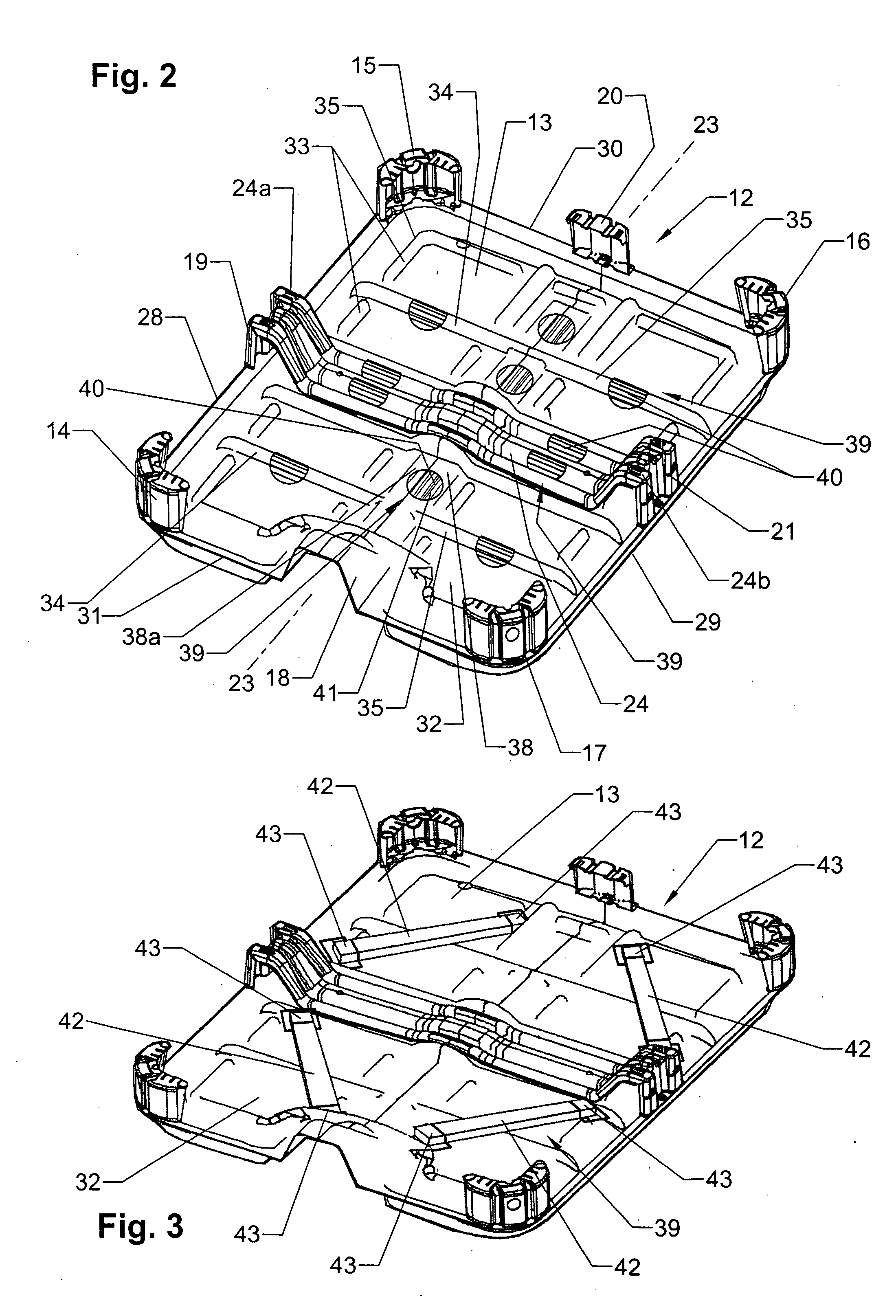

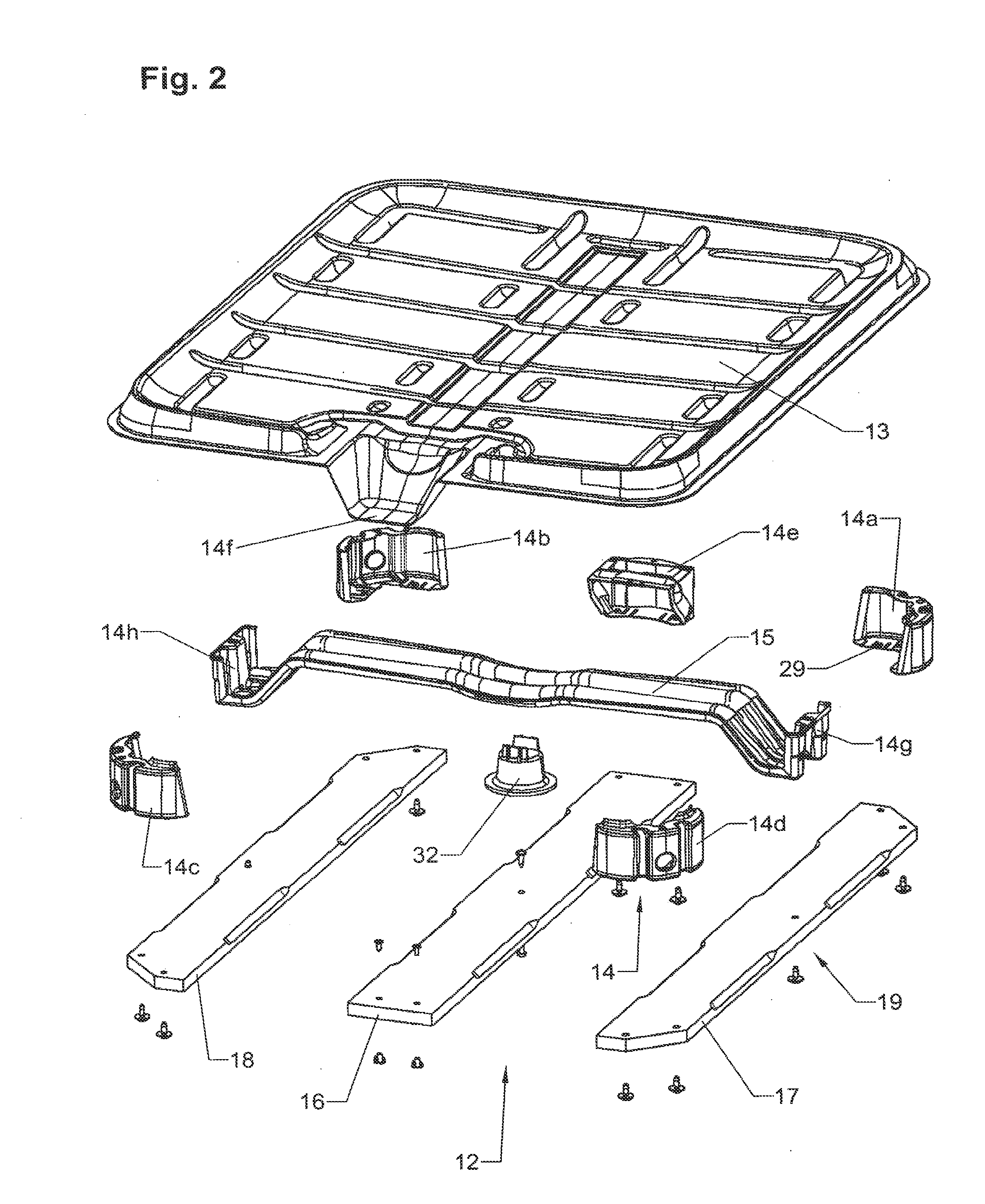

Pallet-like support base for transport and storage containers for liquids

InactiveUS20050092639A1Improve transport safetyIncrease coefficient of frictionOther accessoriesContainer/bottle contructionPlastic materialsTransport medium

A pallet-like support base for transport and storage containers for liquids includes an inner container of plastics material and an outer jacket of a metal grid or of sheet metal which is adapted to be manipulated by a forklift, a shelf operating system or a similar transport medium, and with a bottom of metal resting on support legs of metal, a middle runner and two outer runners for supporting the inner container which is equipped with a closable filler connection and a drain connection for connection to a drain fitting. The middle runner and the two outer runners of the support base are constructed as wooden runners.

Owner:PROTECHNA SA

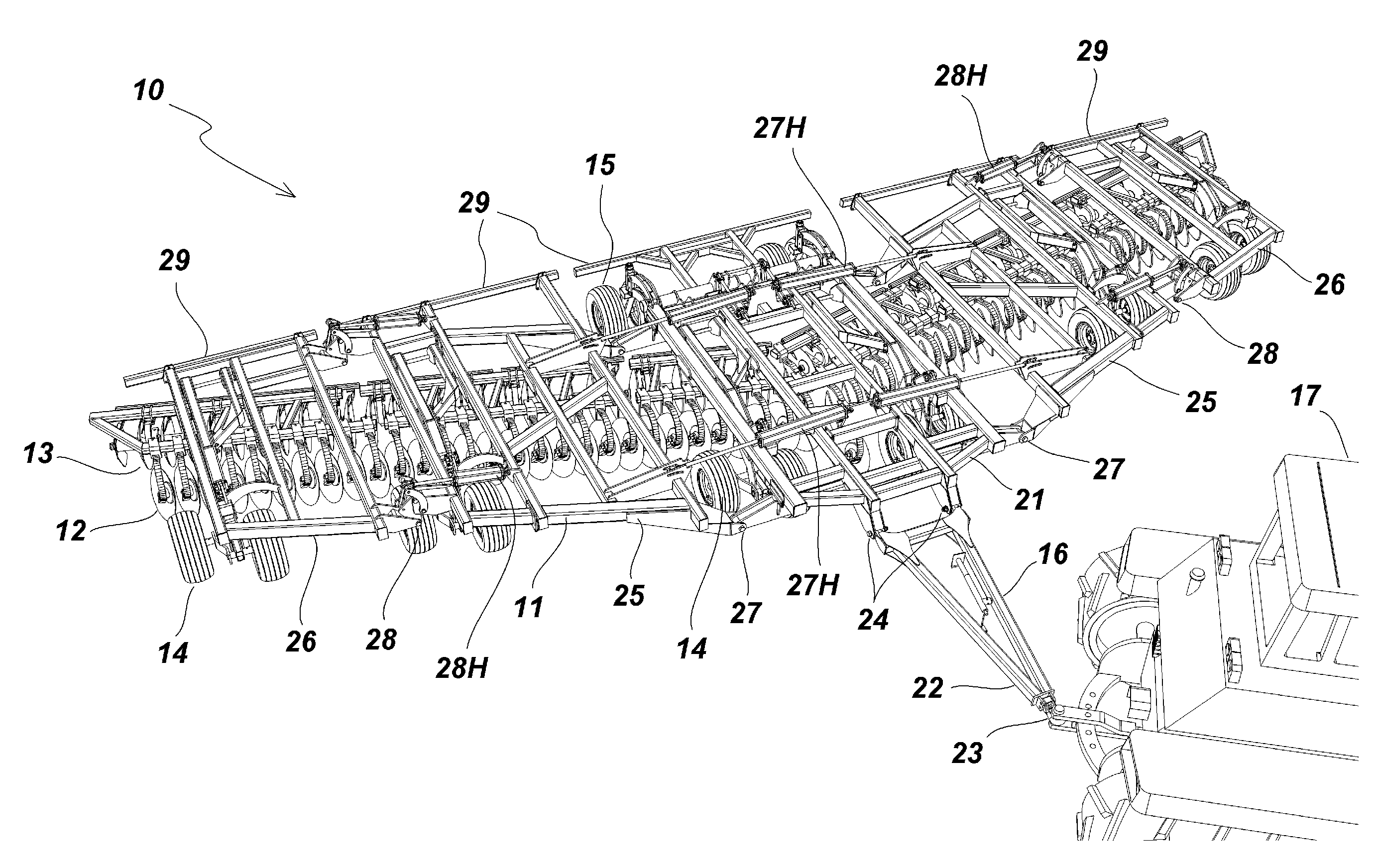

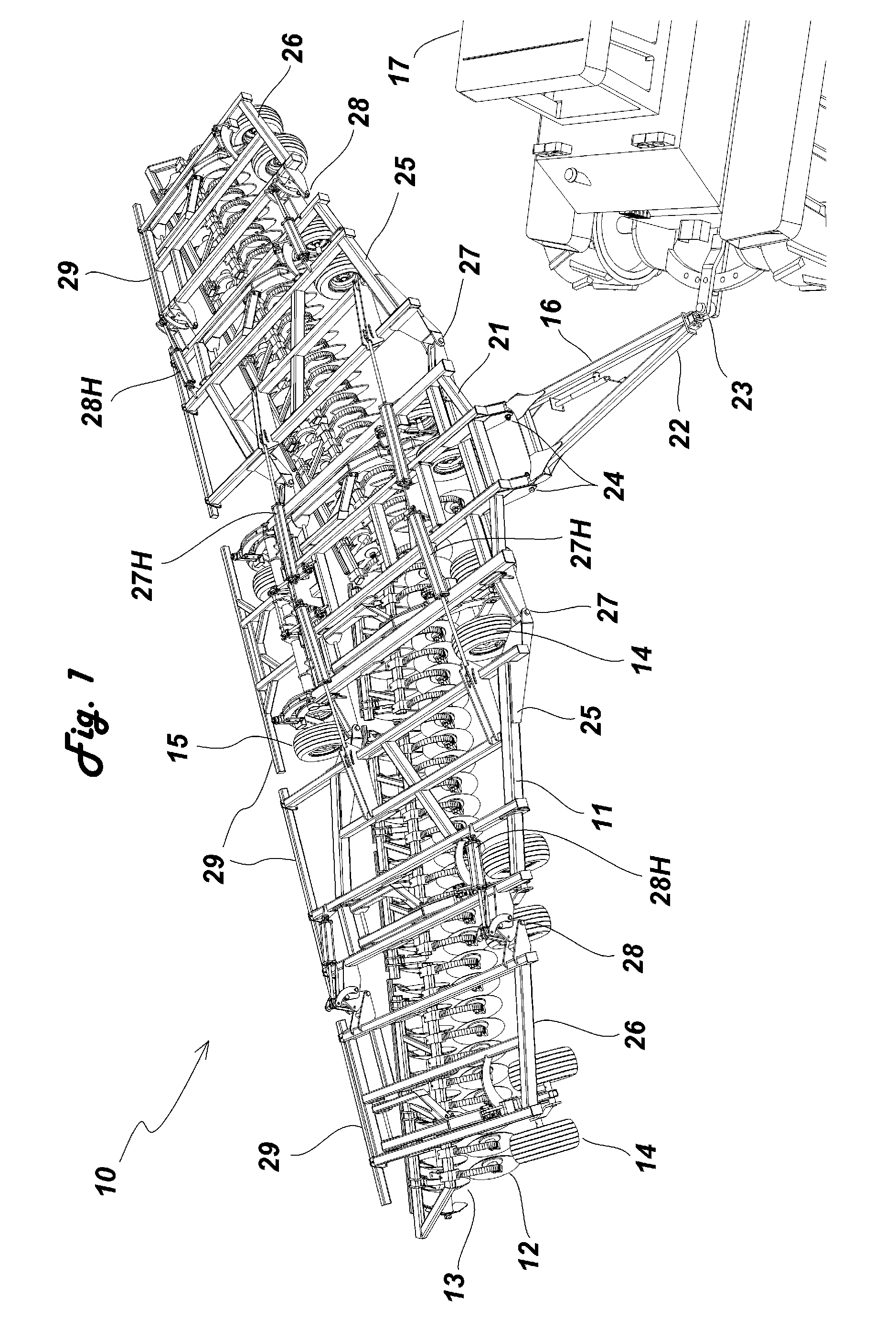

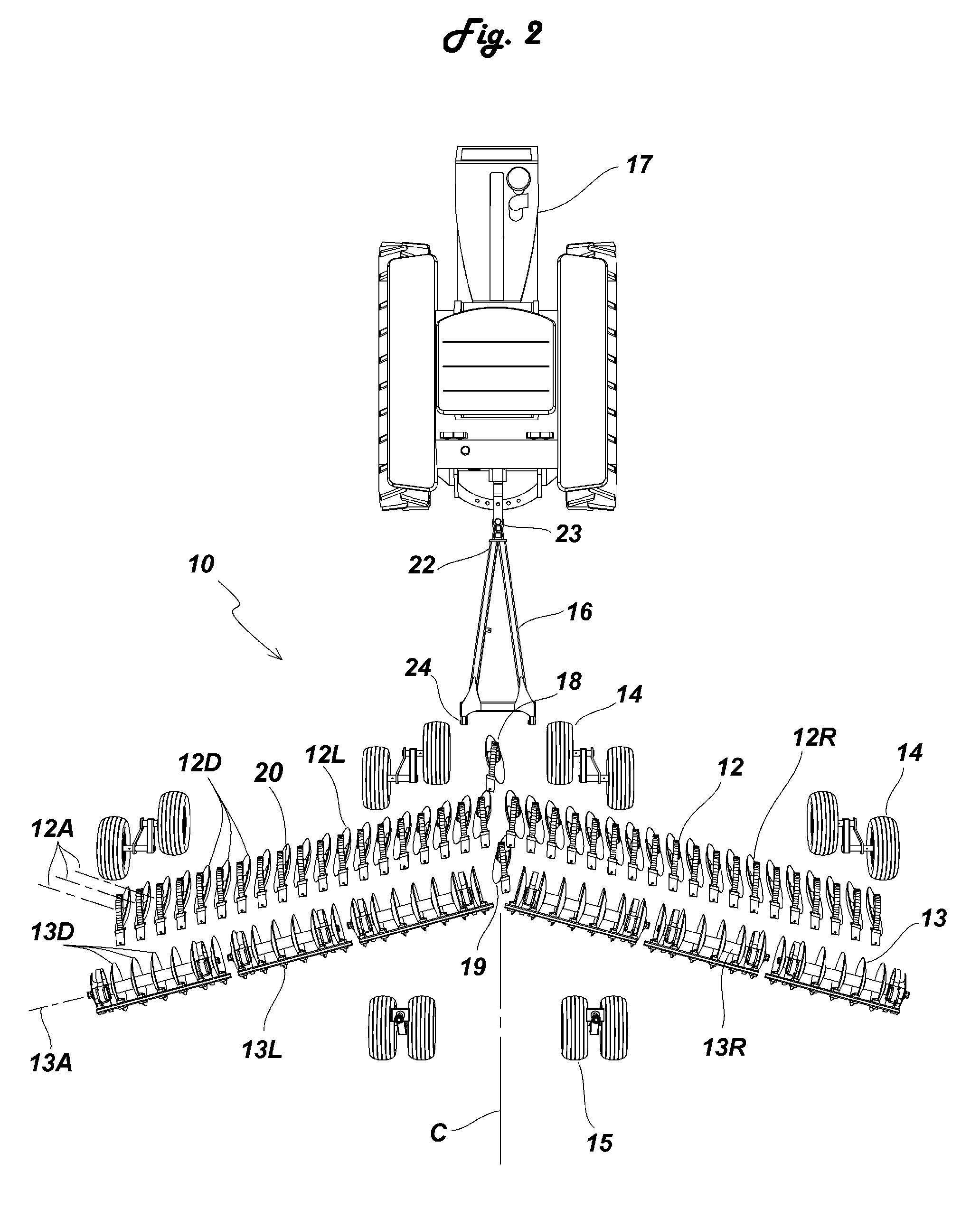

Blade arrangement for disk harrows

InactiveUS20100314144A1Prevents and minimizes divergenceLarge widthSpadesAgricultural machinesCircular discComputer engineering

A multisection tandem disk harrow has a frame, a first disk gang, and a second disk gang. The concave sides of the disk blades in the first disk gang face one side of the disk harrow, and the concave sides of the disk blades in the second disk gang face the other side of the disk harrow. The disk blades in the first disk gang are mounted for rotation about a common axis that extends through a center of the disk blades. The disk blades in the second disk gang are mounted for rotation about respective individual axes that are substantially parallel with and spaced apart from each other. The first and second disk gangs are arranged so that the common axis of the first disk gang is nonparallel with the individual axes of the second disk gang. Various frame, support wheels, disk gang, and hitch configurations are also disclosed.

Owner:HENNES MARK

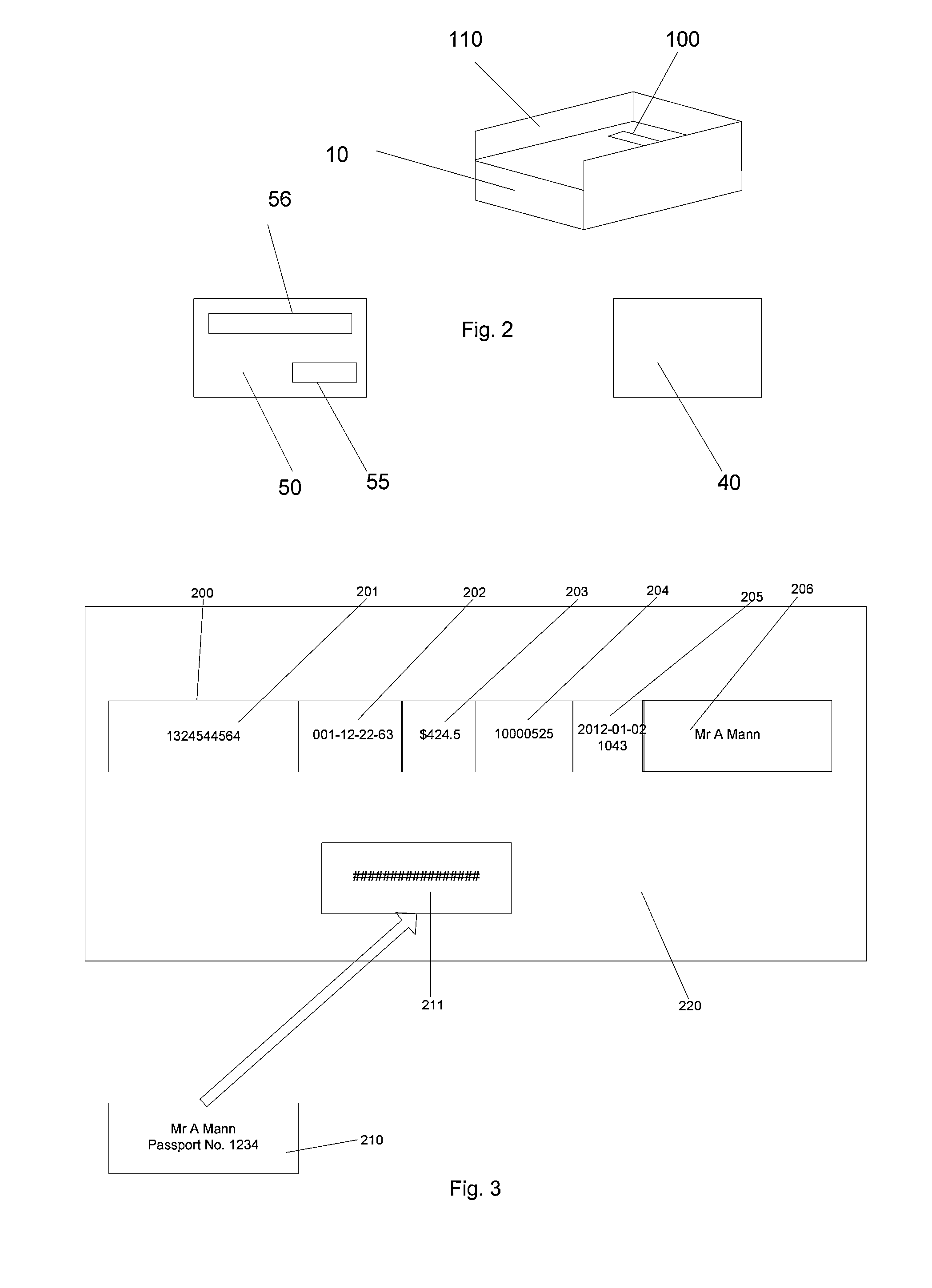

Payment unit, system and method

InactiveUS20150161594A1Improve the level ofReduce ticket fraudAcutation objectsFinancePaymentCard reader

A payment unit, method and system are disclosed. In one arrangement, the payment unit includes a payment card reader to participate in a payment communication to obtain payment data, a secondary reader to obtain supplementary data from a machine readable entity that is physically proximate to the unit, the supplementary data being obtained via a communication that is separate from the payment communication, and a controller to operate the payment card reader and secondary reader and to generate a payment record from said payment data and said supplementary data.

Owner:VANCLARE SE

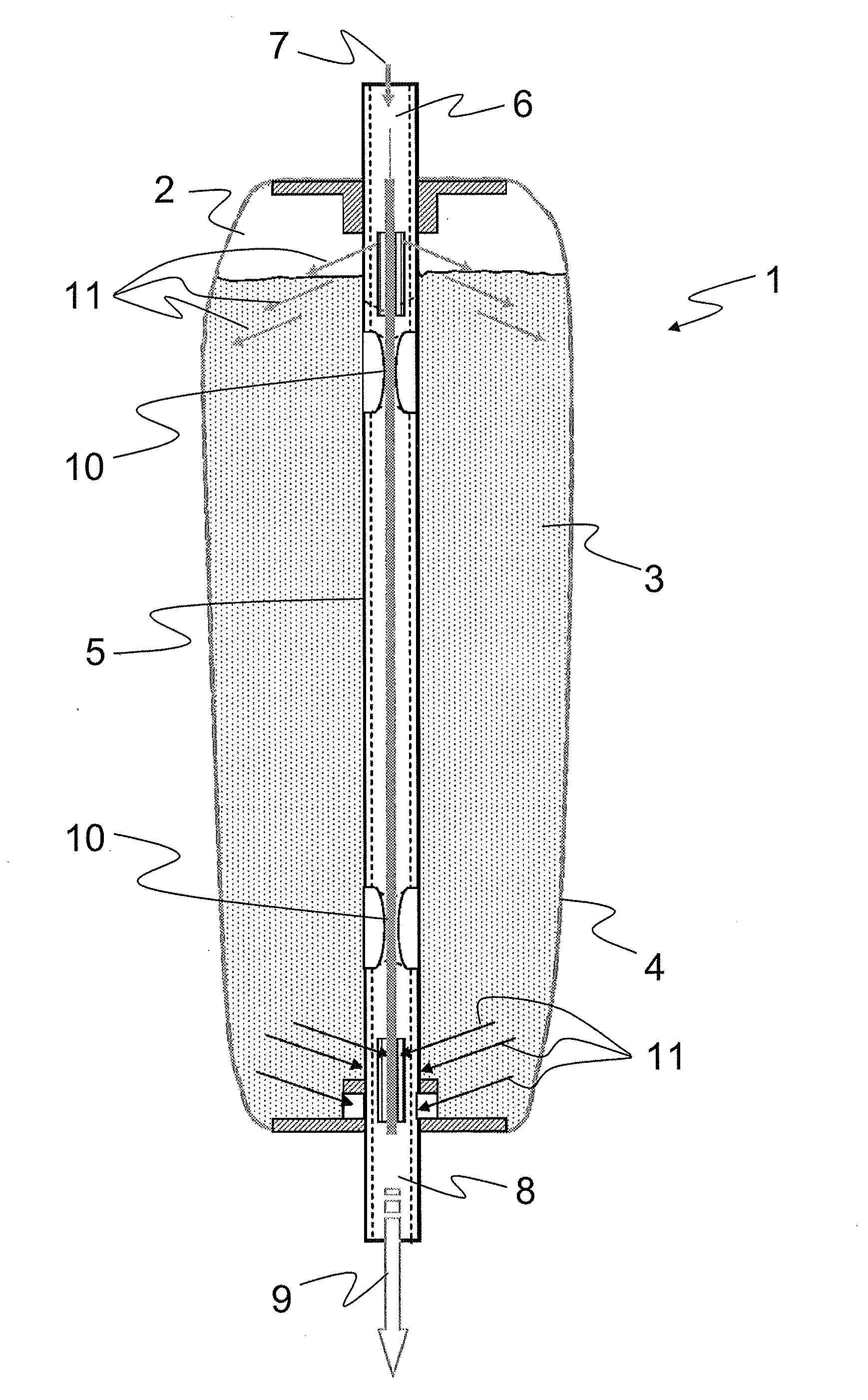

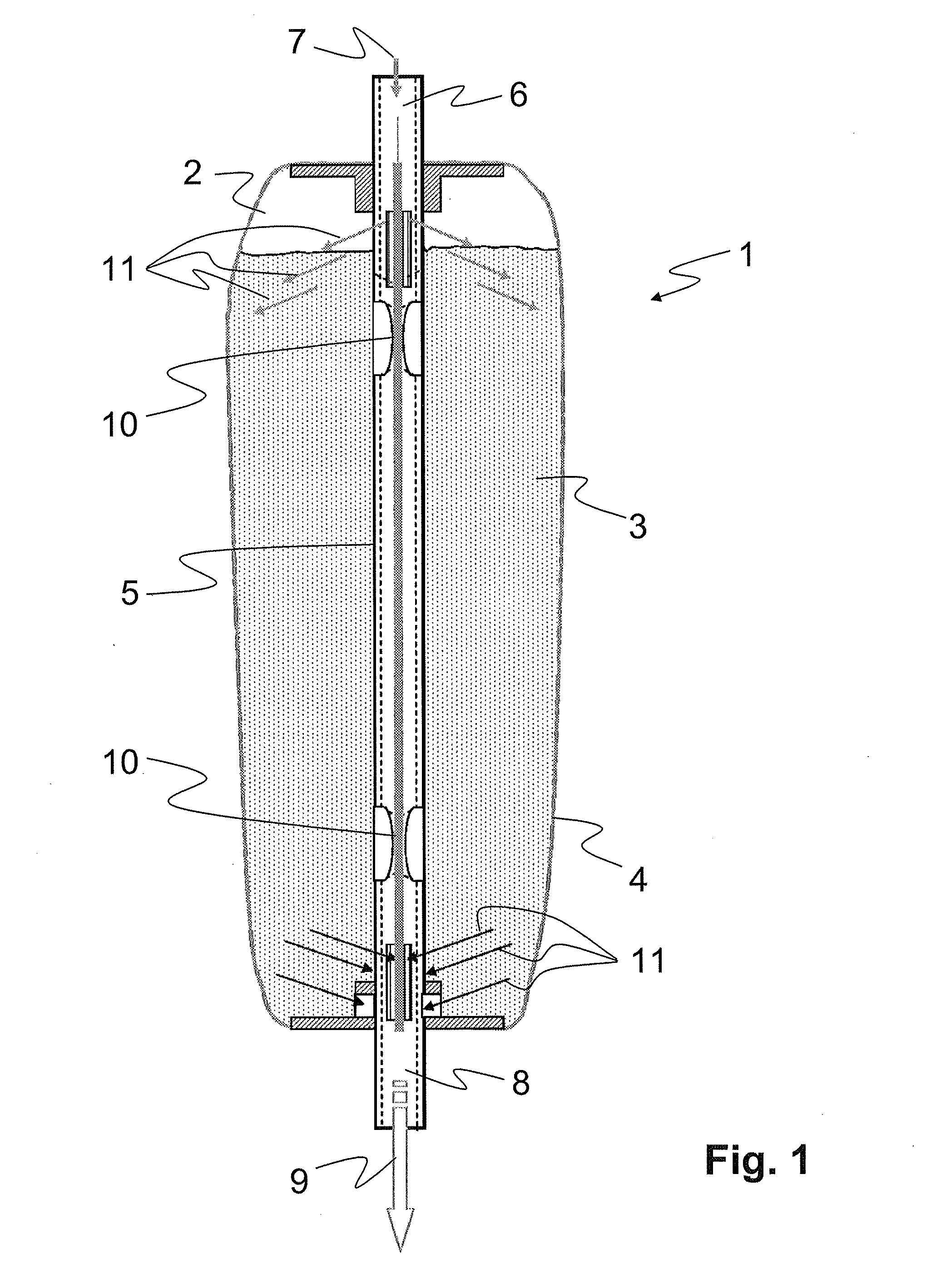

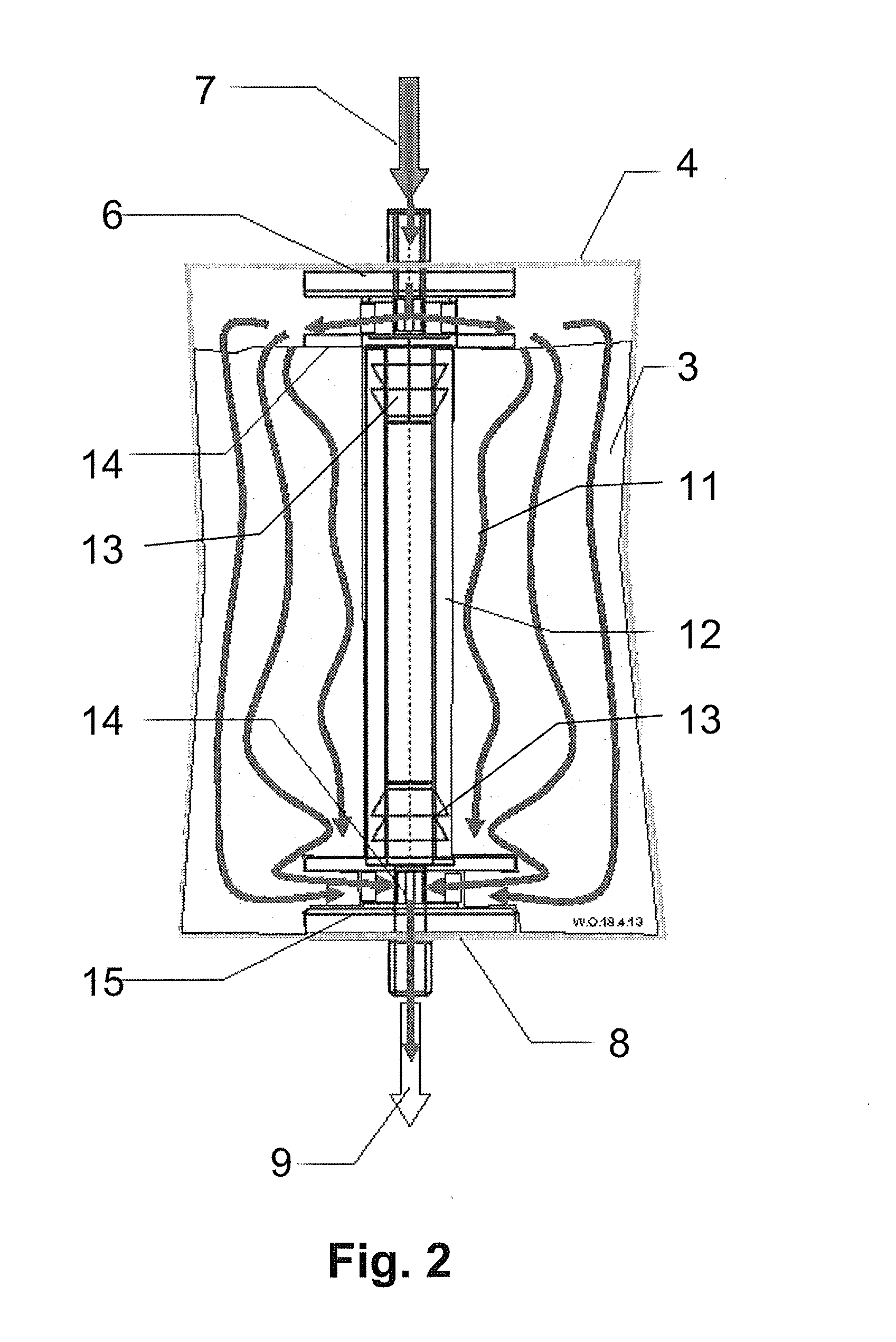

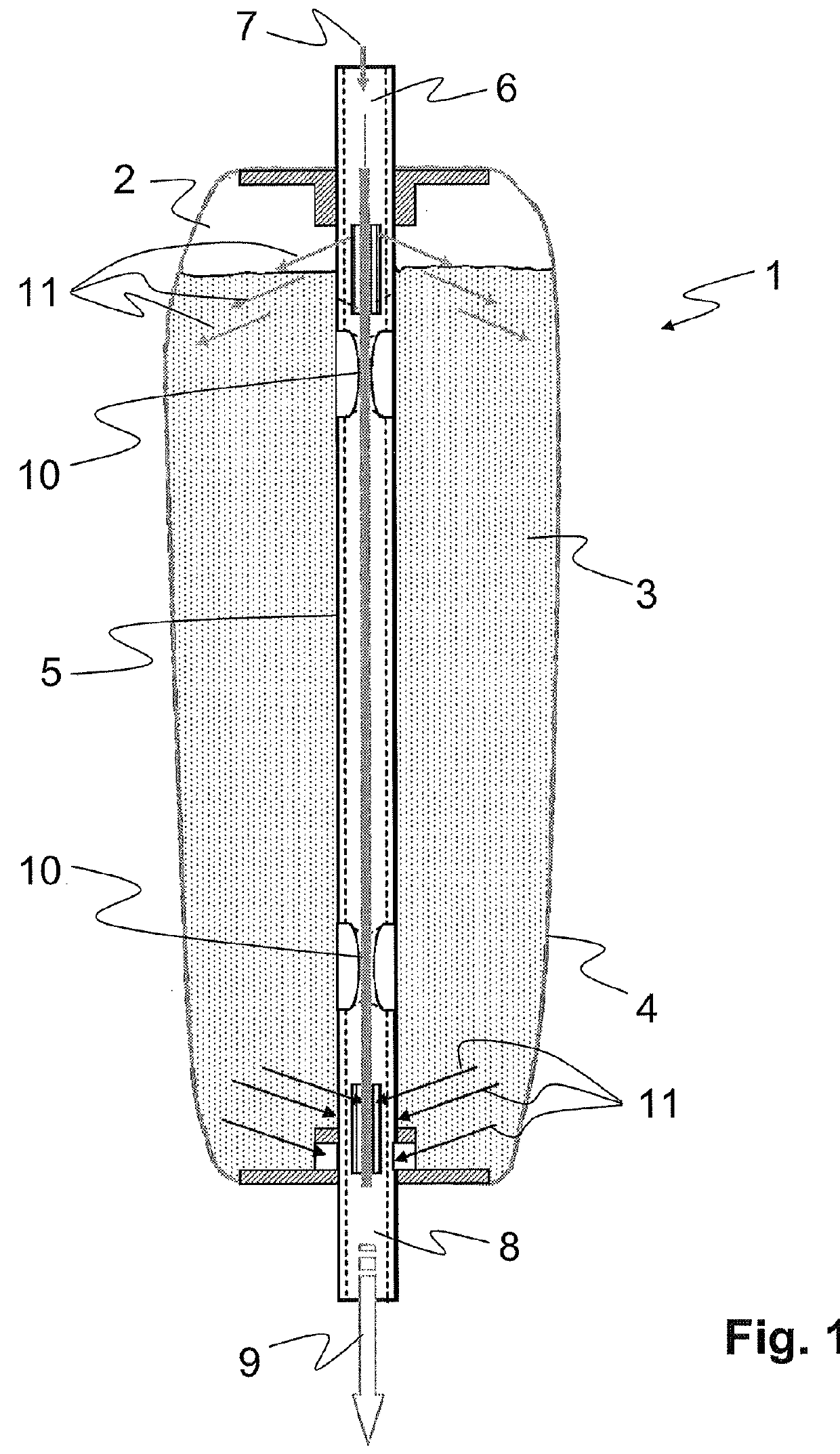

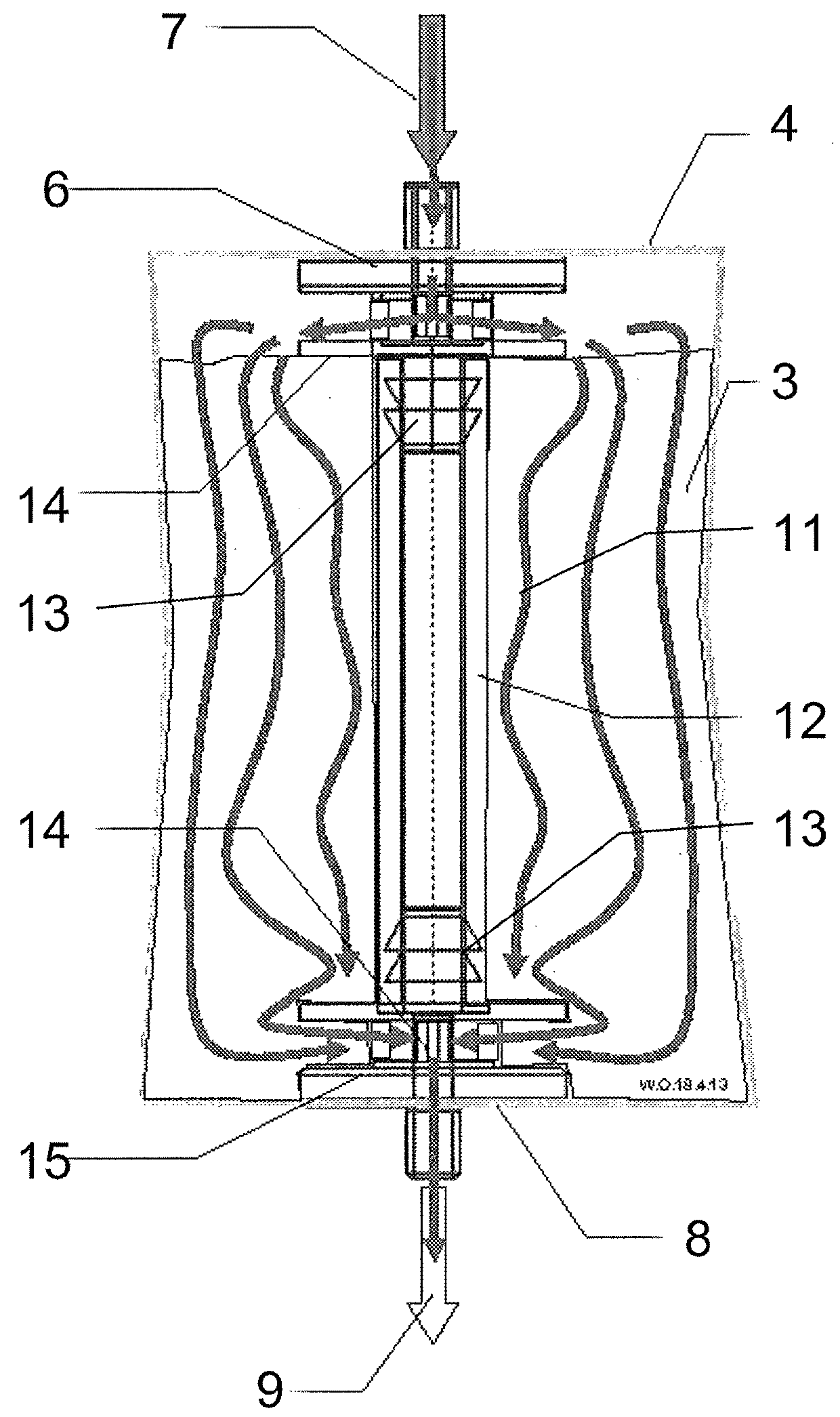

Device for preparing a solution, in particular in or on a dialysis machine

ActiveUS20150029817A1Low costEliminate disadvantagesFlow mixersDialysis systemsSolventBiomedical engineering

Devices for preparing a liquid solution are disclosed. The device includes a receptacle defining a cavity for receiving at least one active substance to be dissolved, at least one inlet leading into the cavity for feeding at least one solvent into the cavity, and at least one outlet leading out of the cavity for discharging the liquid solution including the at least one active substance and the at least one solvent from the cavity. The cavity or the receptacle may include a flexible outer shell for enclosing the cavity and an inner, preferably columnar, supporting element for stretching the flexible outer shell between at least two points, the supporting element comprising the at least one inlet at its first end and the at least one outlet at its second end and being enclosed by the flexible outer shell to provide an axially rigid cartridge that can be used in currently customary dialysis machines comprising cartridge connection systems, which can be produced at low cost.

Owner:B BRAUN AVITUM

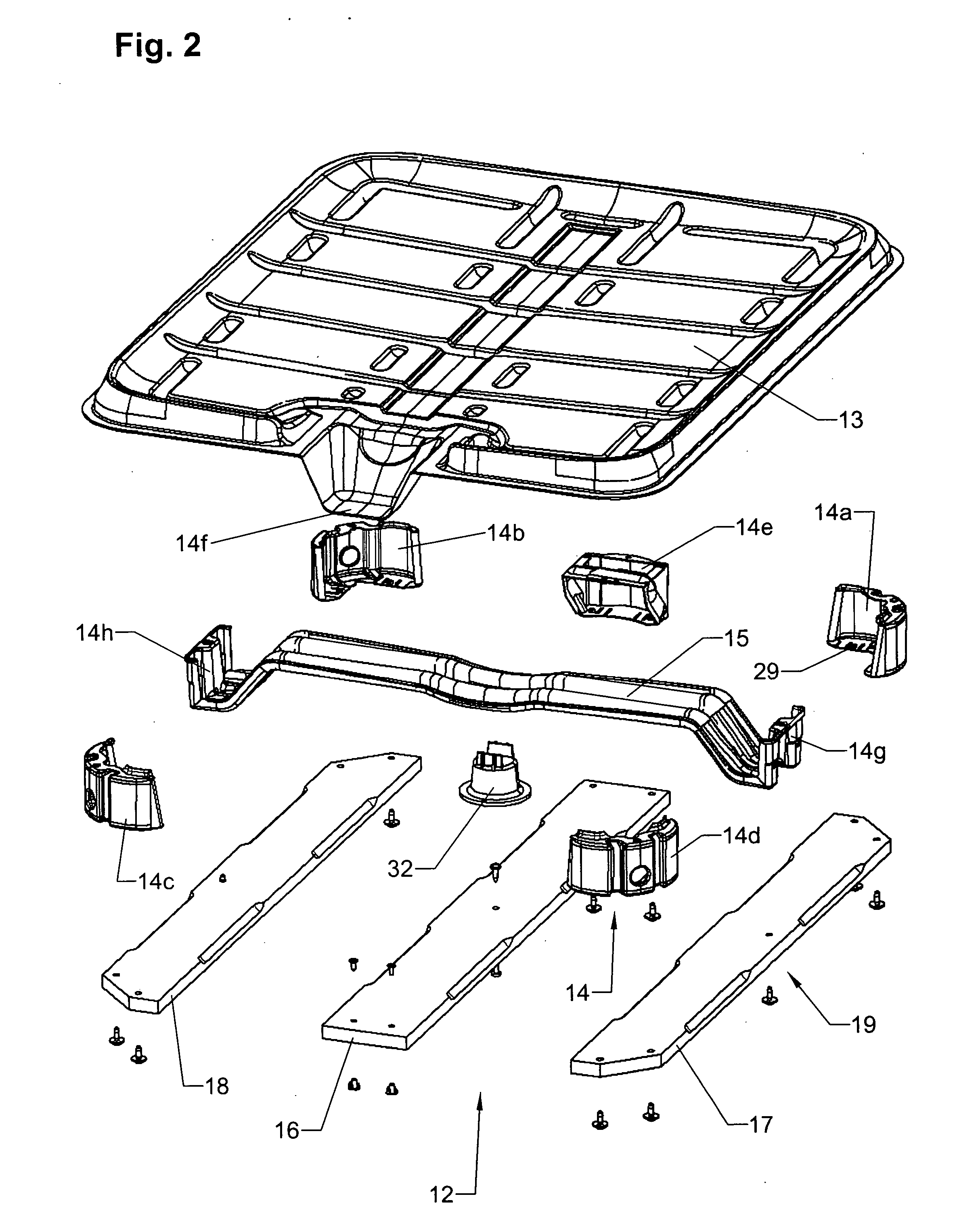

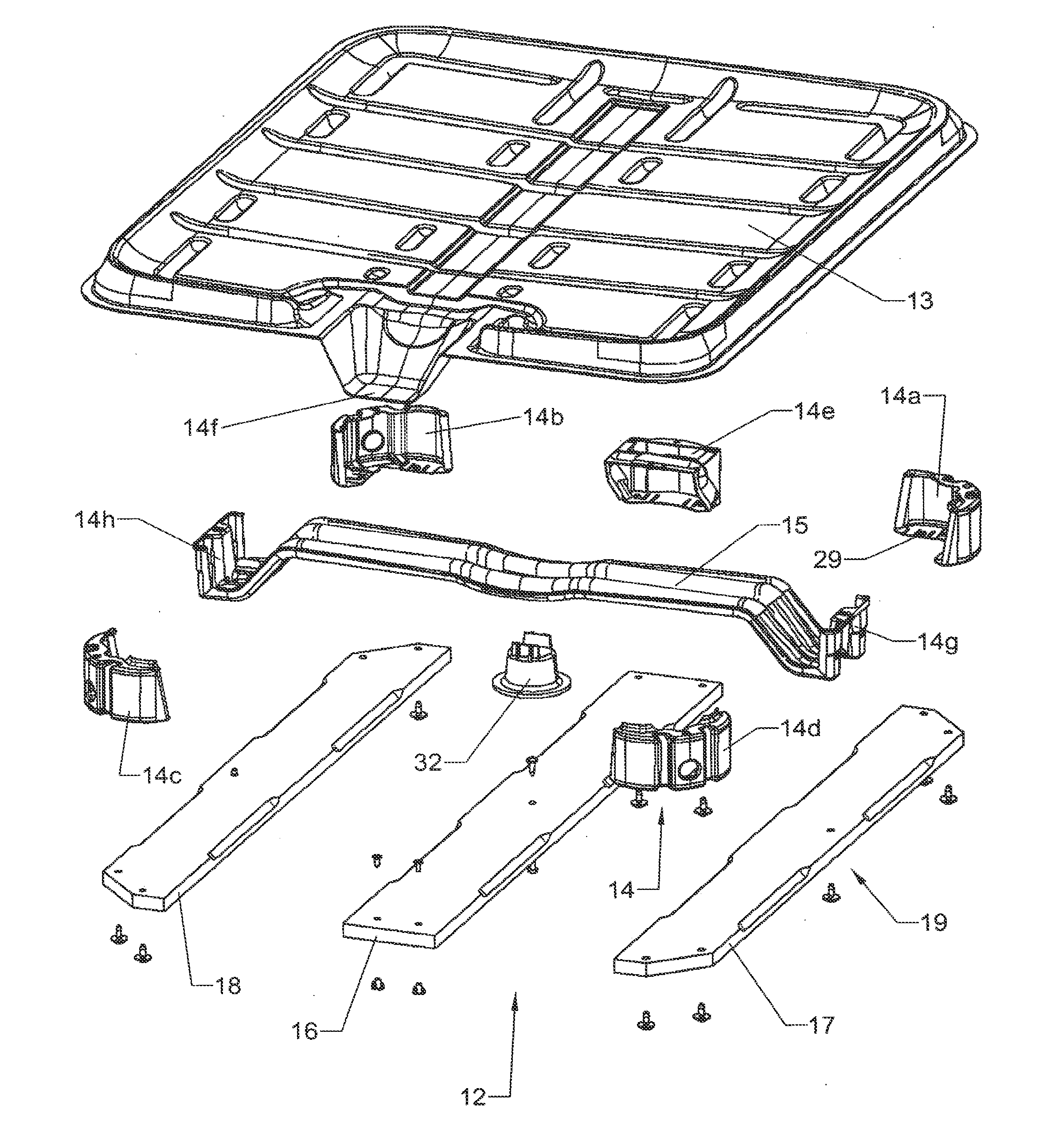

Pallet-type support frame for transport and storage containers for liquids

ActiveUS7107912B2Improve transport safetyTransportation safetyLarge containersRigid containersBraced frameEngineering

A pallet-type support frame for transport and storage containers for liquids having an inner plastic container and an outer metal jacket has a sheet metal bottom for supporting the inner container. The bottom has a shape matched to the drainage bottom or the flat bottom of the inner container. Anti-slip support elements are arranged on the underside of the bottom such that the support frame rests with the support elements on gripping arms of a transport device. Alternatively, an anti-slip coating is provided on the underside of the bottom. The coating is engaged by gripping arms of the transport device when the support frame is transported. The support elements or anti-slip coatings are made of a material that is matched to a material of the gripping arms such that a friction coefficient as great as possible is provided between the support elements or anti-slip coatings and the gripping arms.

Owner:PROTECHNA SA

Pallet-type support frame for transport and storage containers for liquids

ActiveUS20050115473A1Coefficient of frictionTransportation safetyLarge containersRefuse transferringBraced framePallet

A pallet-type support frame for transport and storage containers for liquids having an inner plastic container and an outer metal jacket has a sheet metal bottom for supporting the inner container. The bottom has a shape matched to the drainage bottom or the flat bottom of the inner container. Anti-slip support elements are arranged on the underside of the bottom such that the support frame rests with the support elements on gripping arms of a transport device. Alternatively, an anti-slip coating is provided on the underside of the bottom. The coating is engaged by gripping arms of the transport device when the support frame is transported. The support elements or anti-slip coatings are made of a material that is matched to a material of the gripping arms such that a friction coefficient as great as possible is provided between the support elements or anti-slip coatings and the gripping arms.

Owner:PROTECHNA SA

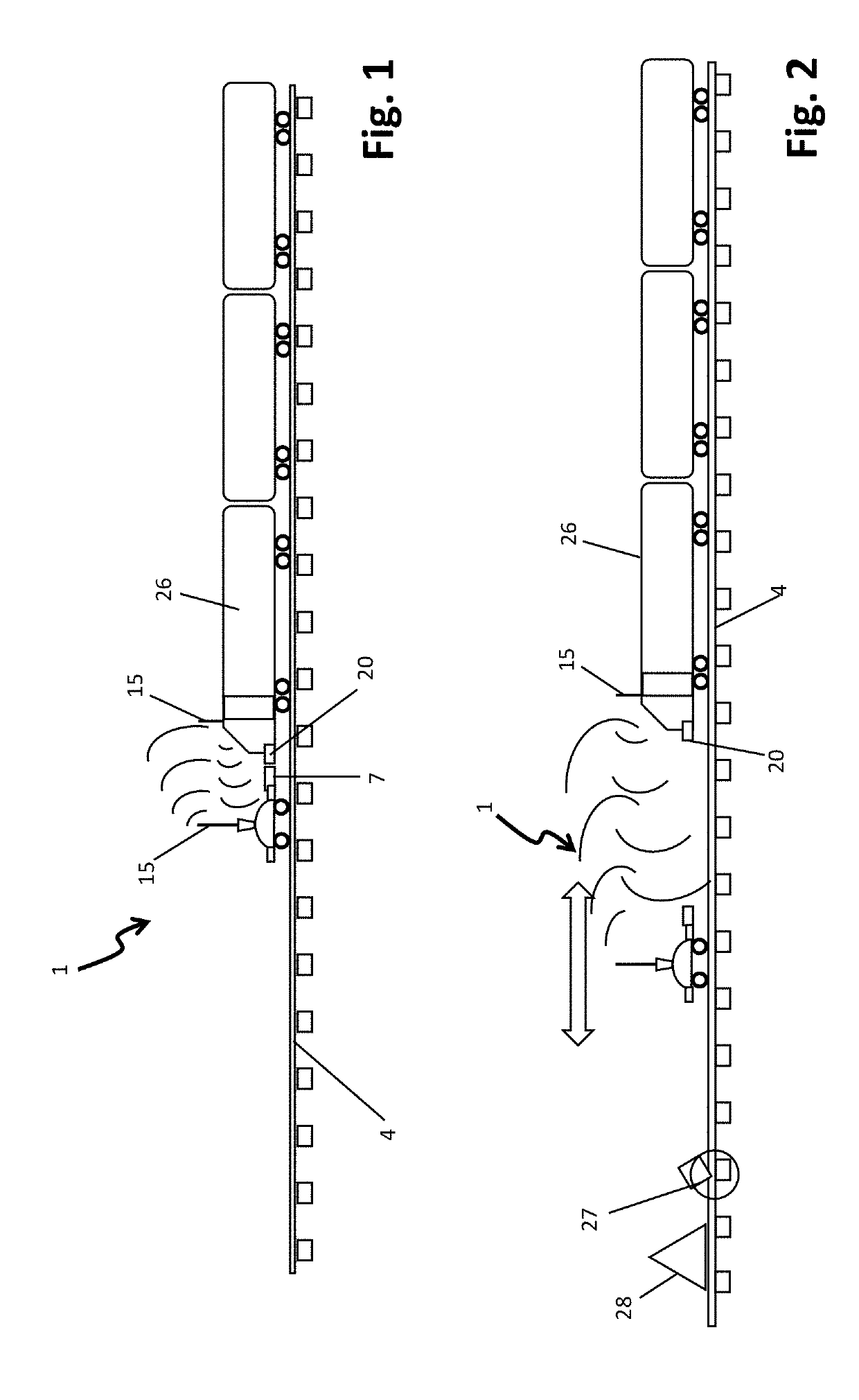

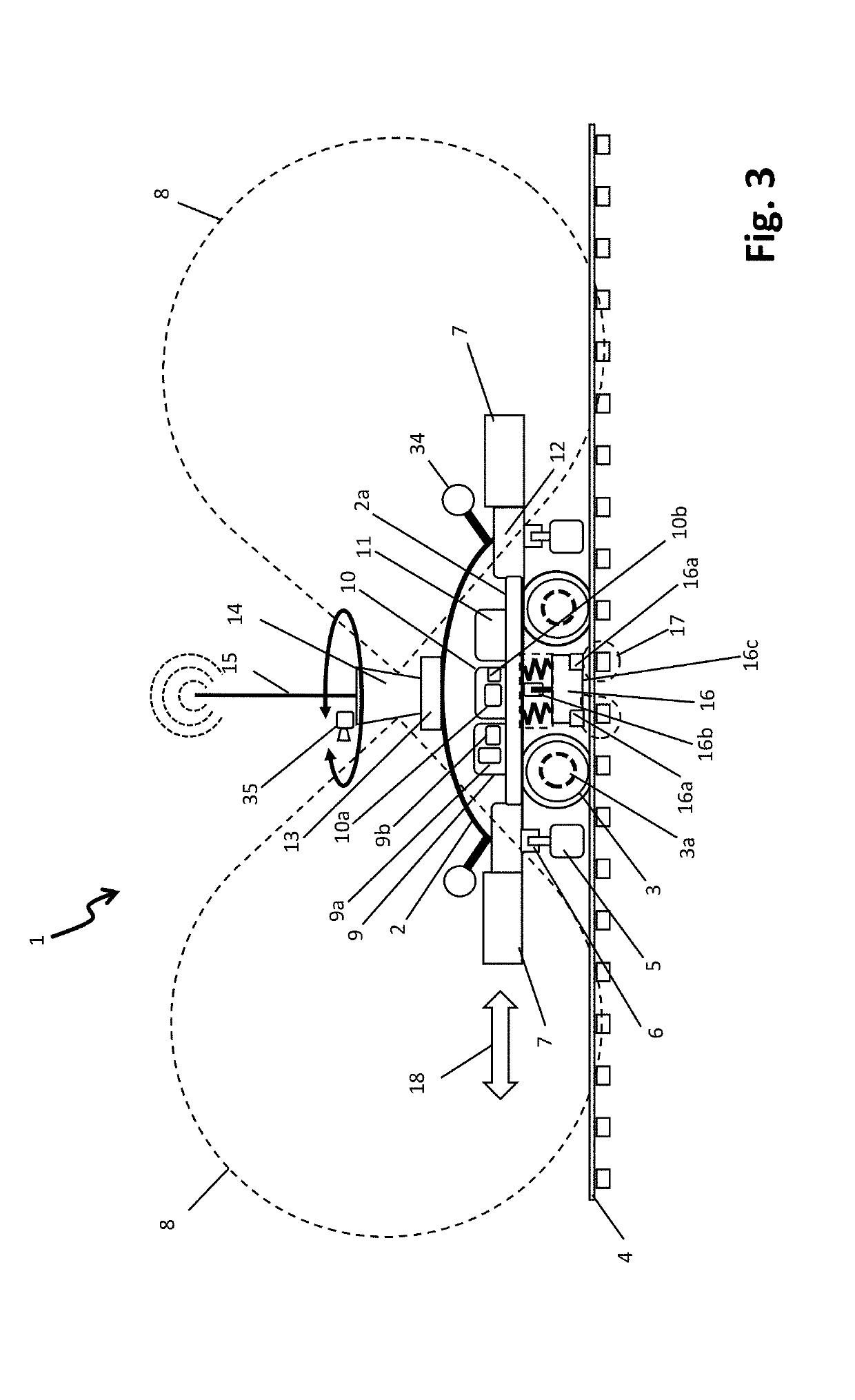

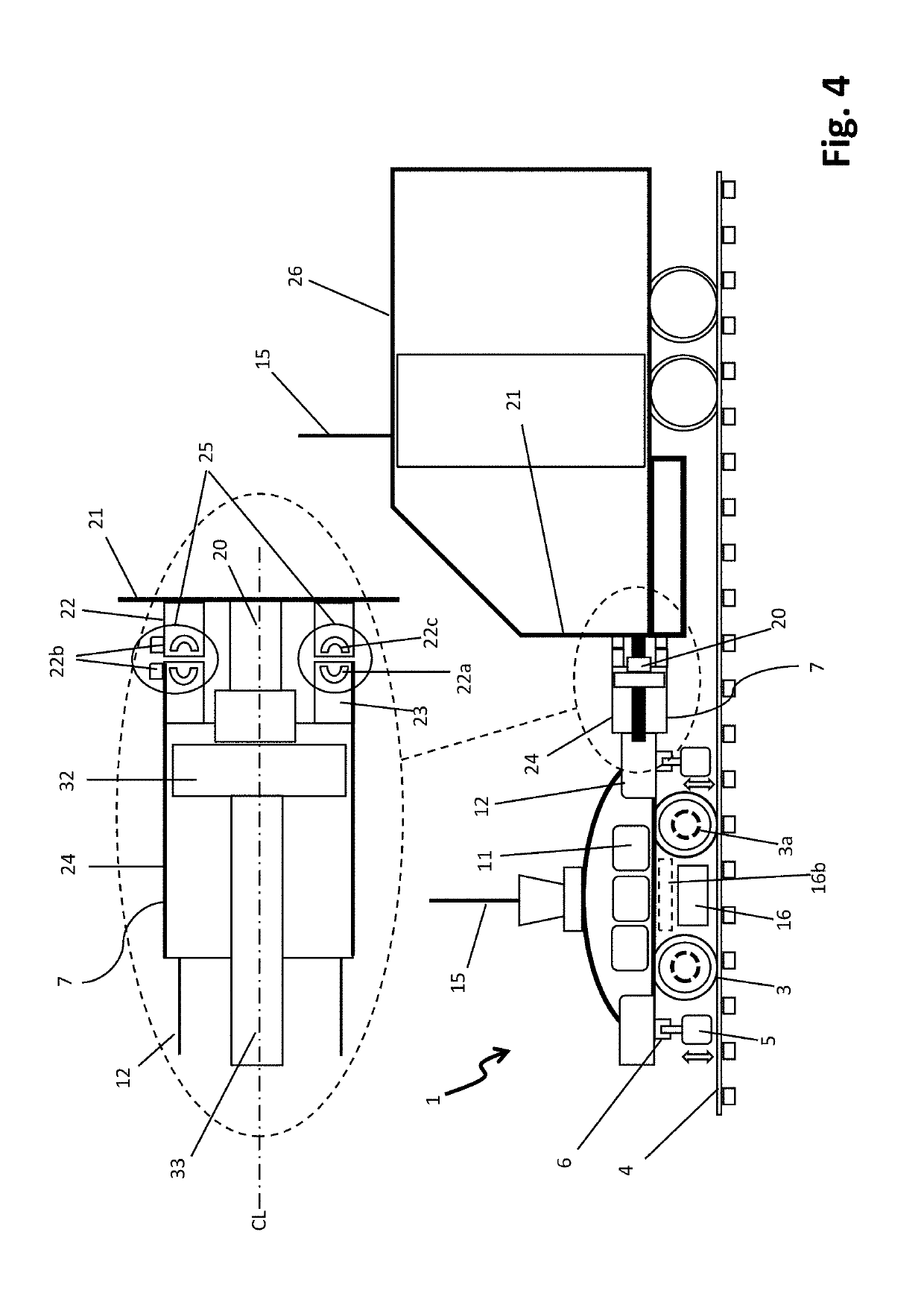

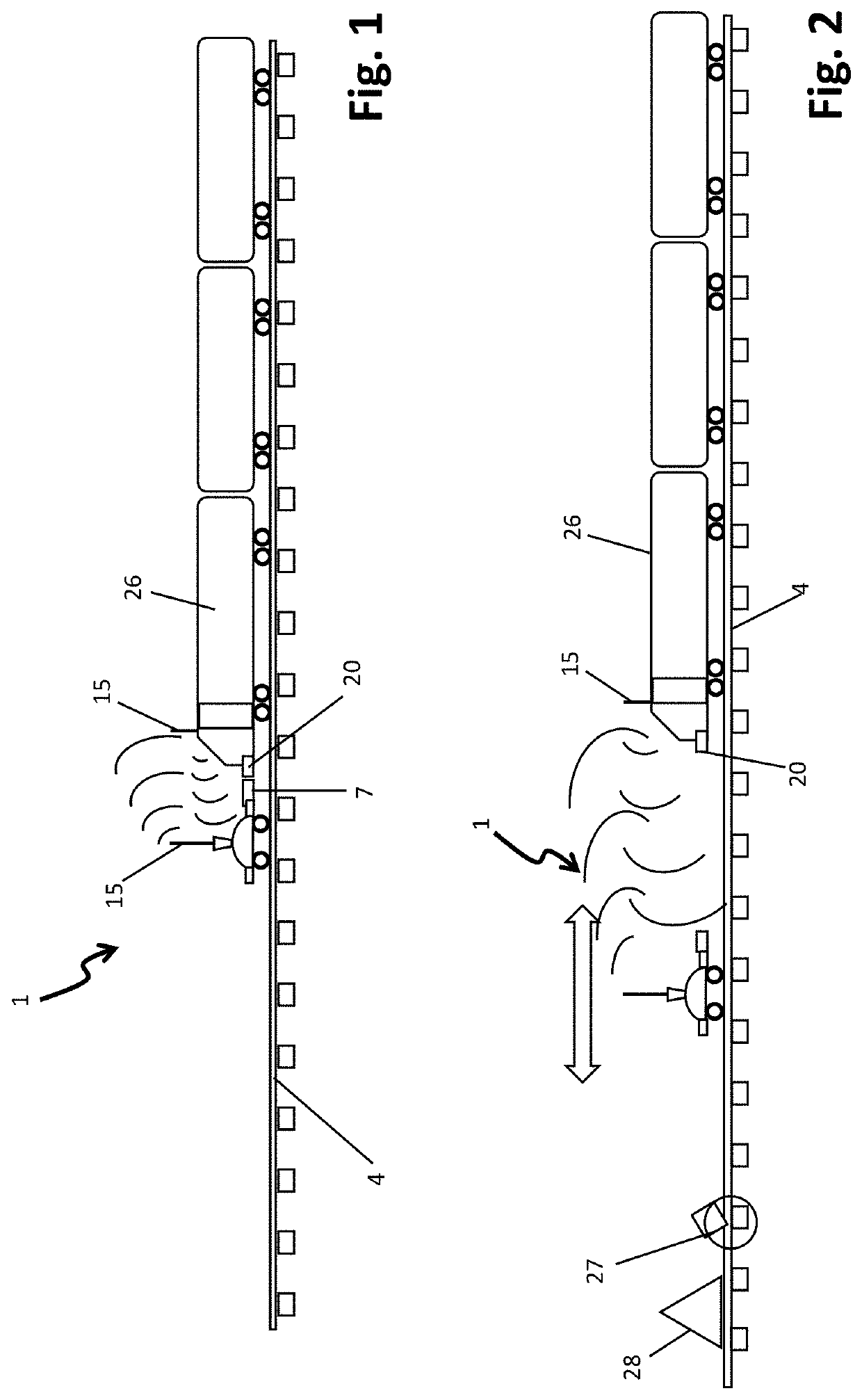

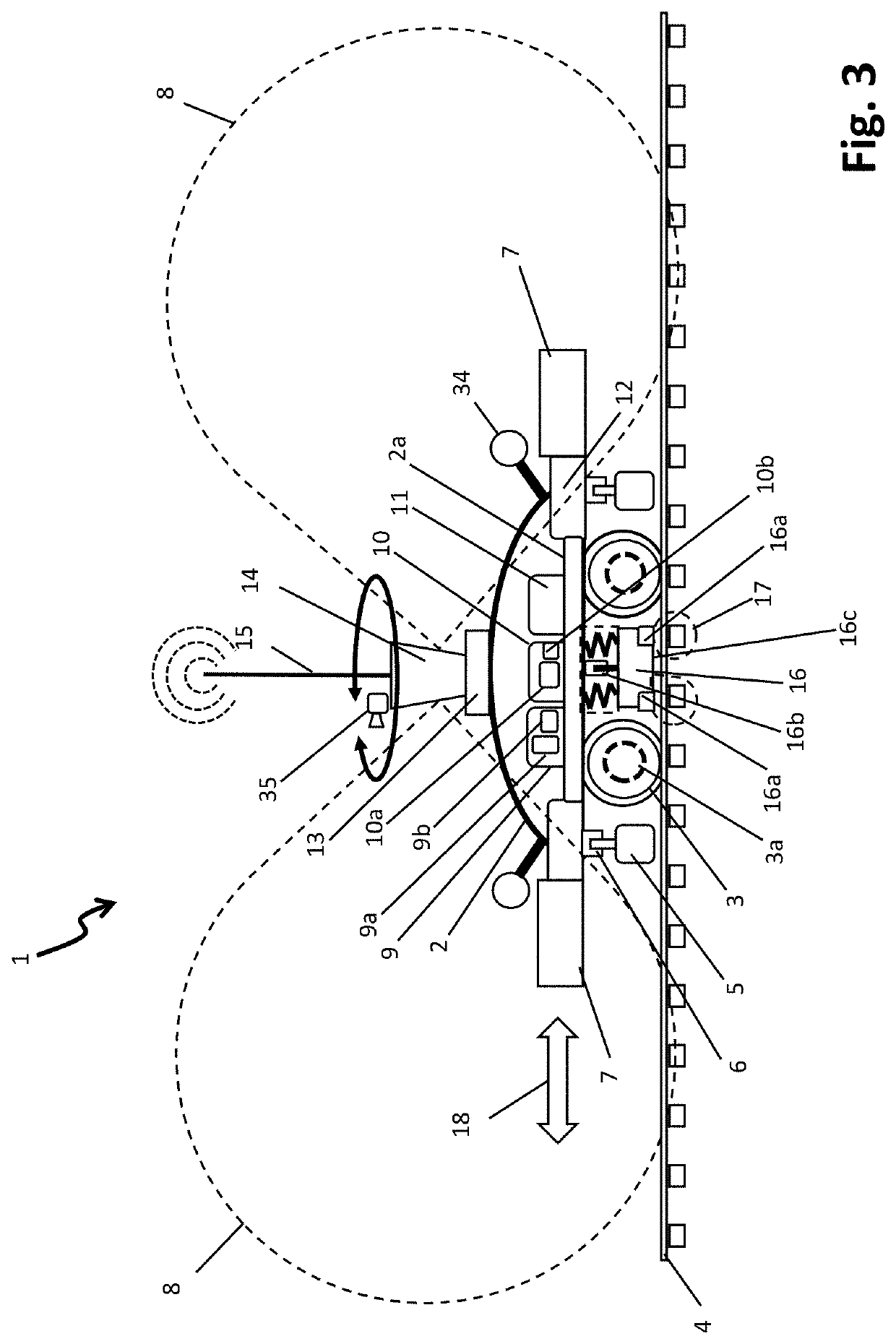

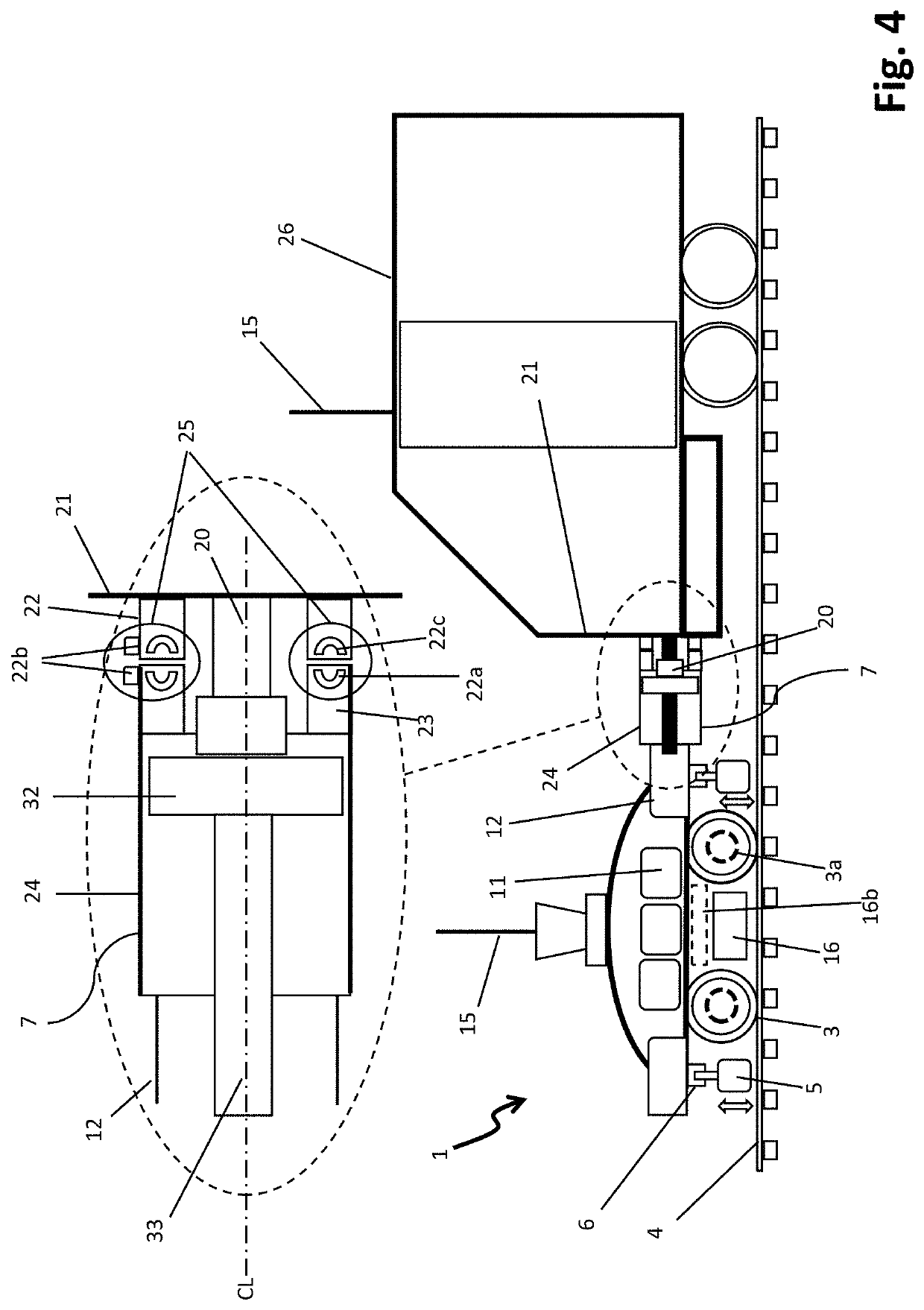

Autonomous scouting rail vehicle

ActiveUS20190256113A1Save livesReduce property damageRailway inspection trolleysSignalling indicators on vehicleOrbitAutomotive engineering

Owner:FILIPPONE CLAUDIO

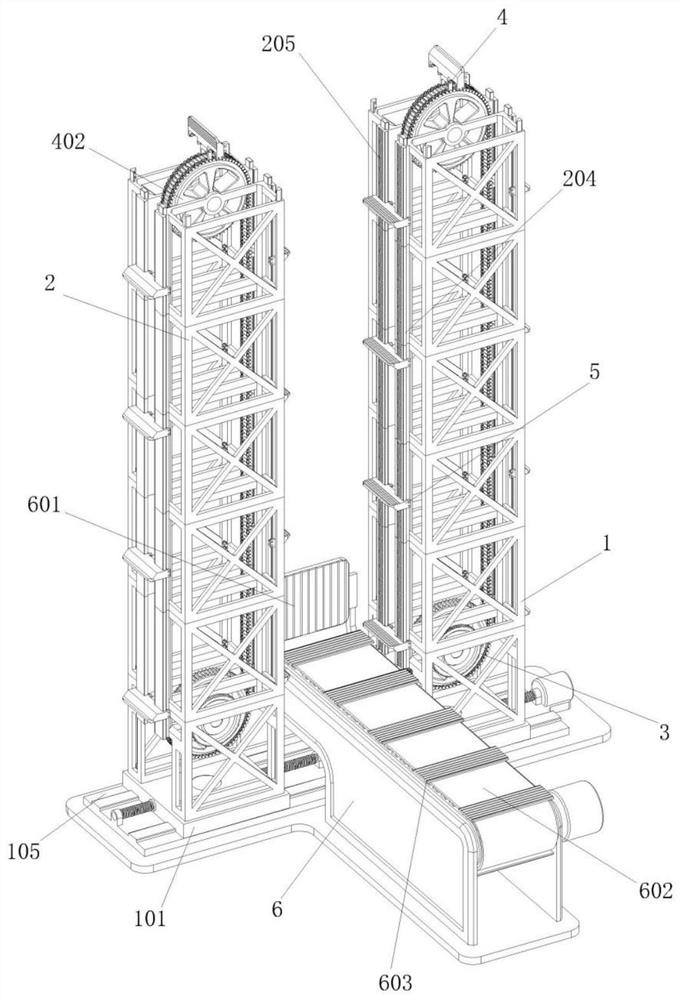

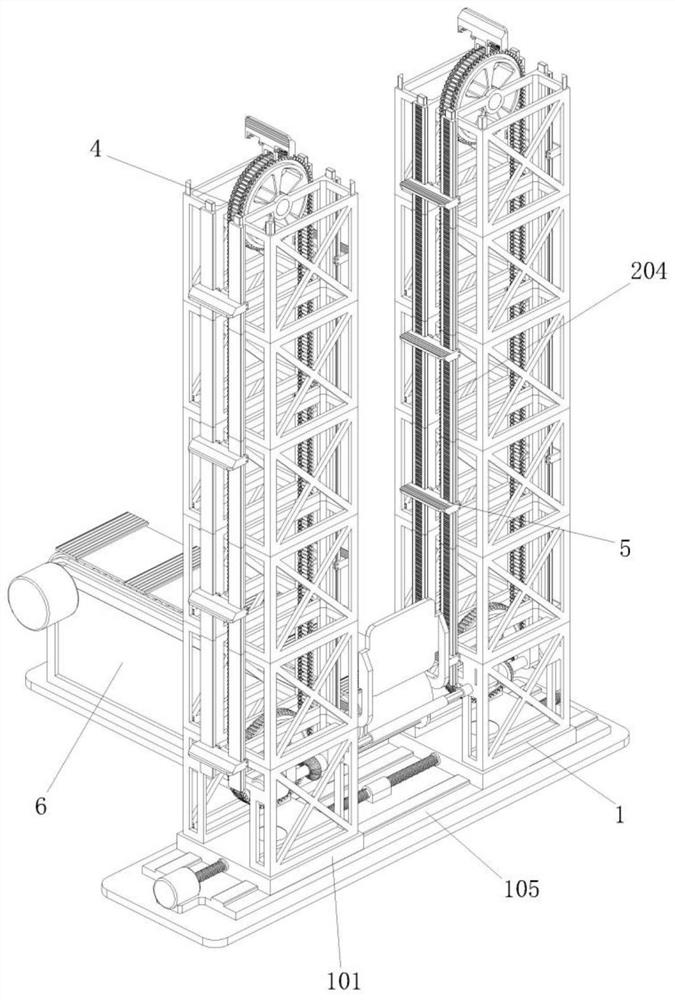

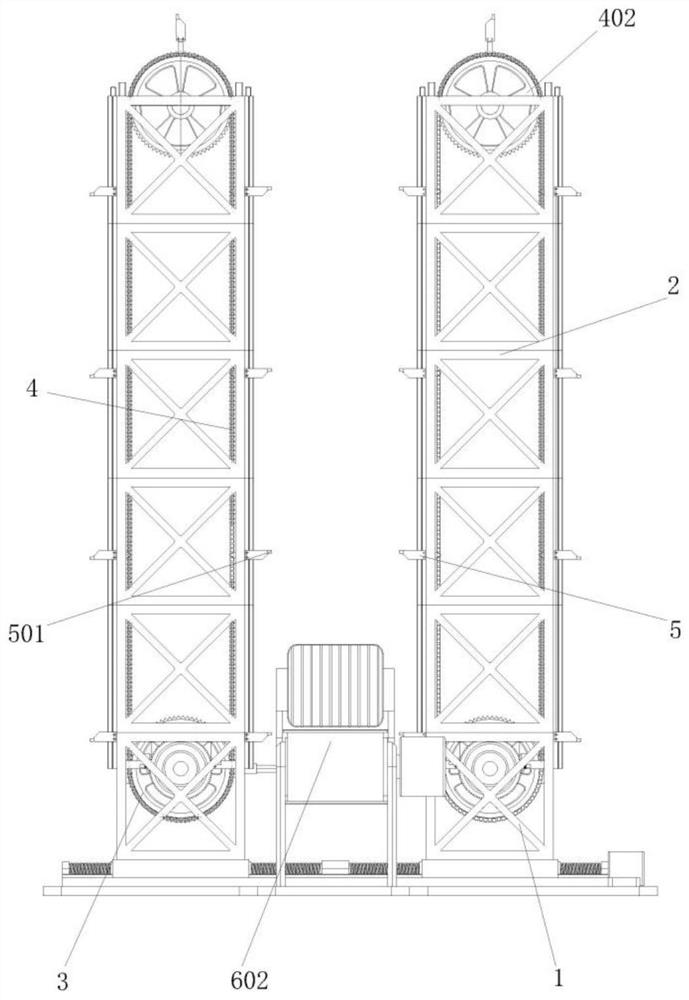

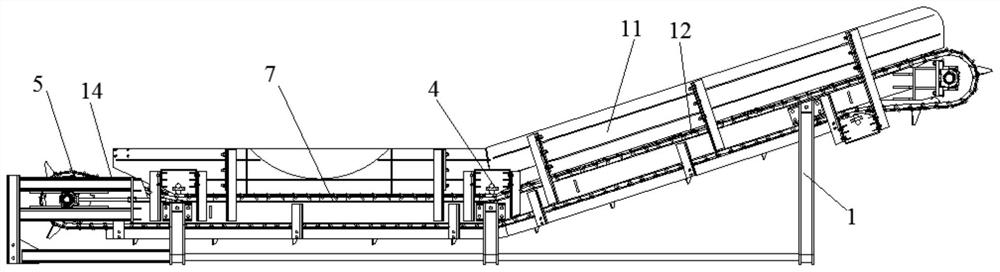

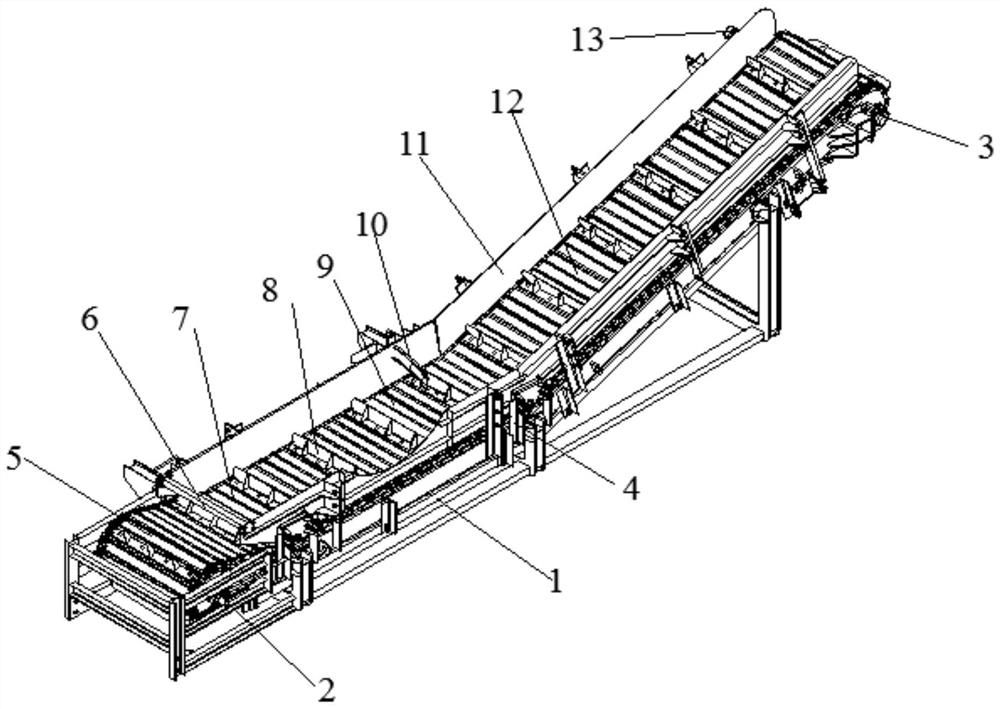

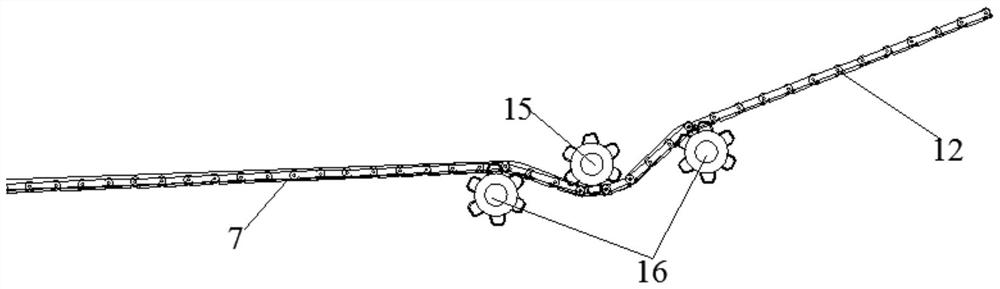

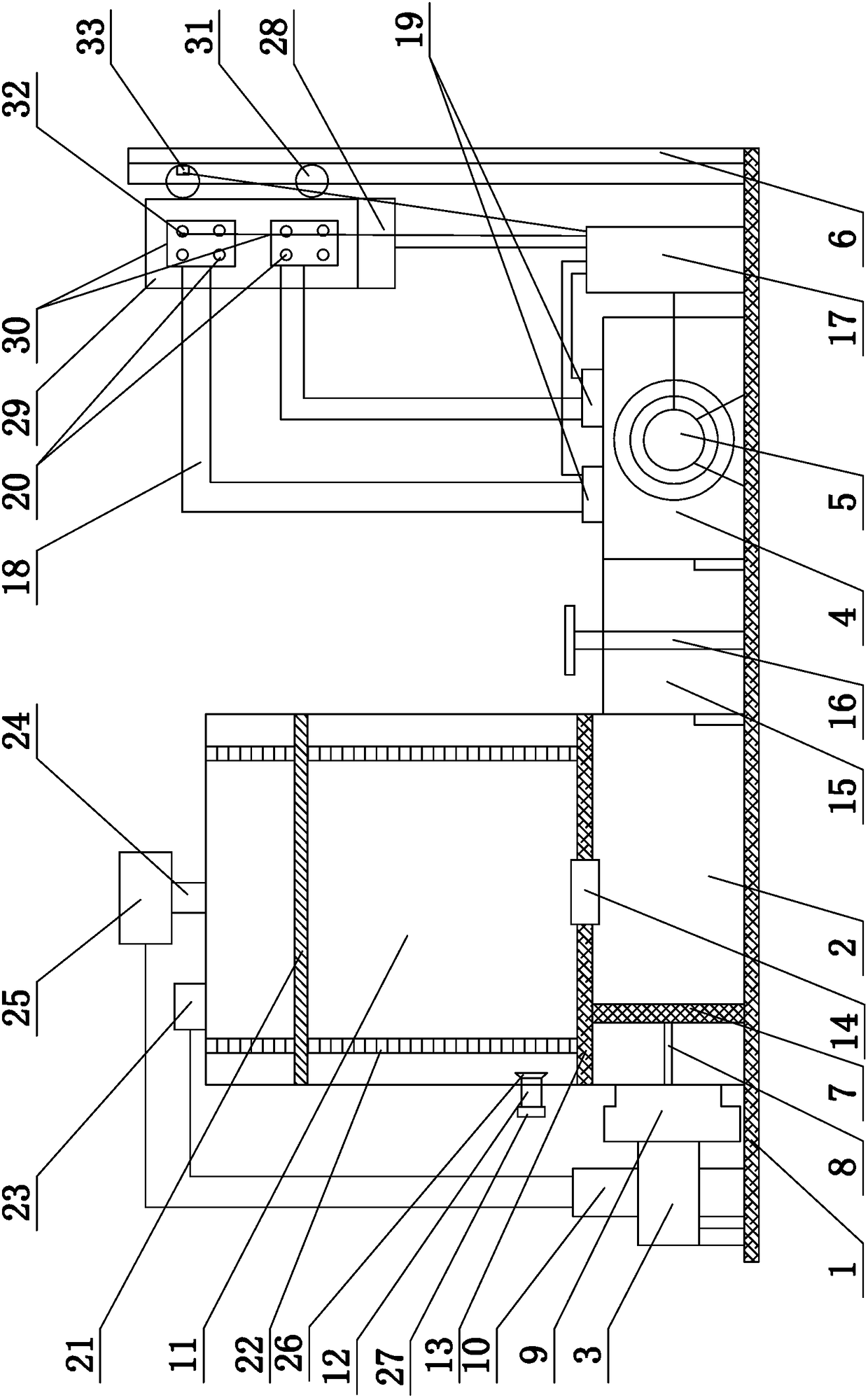

Perpendicular prefabricated member conveying device for assembled building construction

InactiveCN112478606AImprove delivery efficiencyPrevent fallingConveyorsArchitectural engineeringChain link

One or more embodiments of the description provide a perpendicular prefabricated member conveying device for assembled building construction. The device comprises sleeve type brackets, traction gears,traction chains and carrying locking seats, wherein each sleeve type bracket consists of a plurality of split brackets arranged vertically and perpendicularly; the traction gears are arranged on thetop of the sleeve type brackets; the traction chains are arranged on the outer side of the traction gear; the carrying locking seats are uniformly arranged on the outer side of the traction chain, andhorizontal carrying plates are arranged on the outer sides of the carrying locking seats. By arranging the traction chain structures on the symmetrically arranged sleeve type brackets, the carrying locking seats and the horizontal carrying plates are uniformly and symmetrically arranged on each traction chain. By moving the traction chains to drive all the horizontal carrying plates to move perpendicularly and circularly along the sleeve type brackets, each pair of horizontal carrying plates can carry a prefabricated member to move upward along the traction chain, so that a plurality of concrete prefabricated members can be conveyed successively at the same time, and the conveying efficiency is higher.

Owner:邓学兰

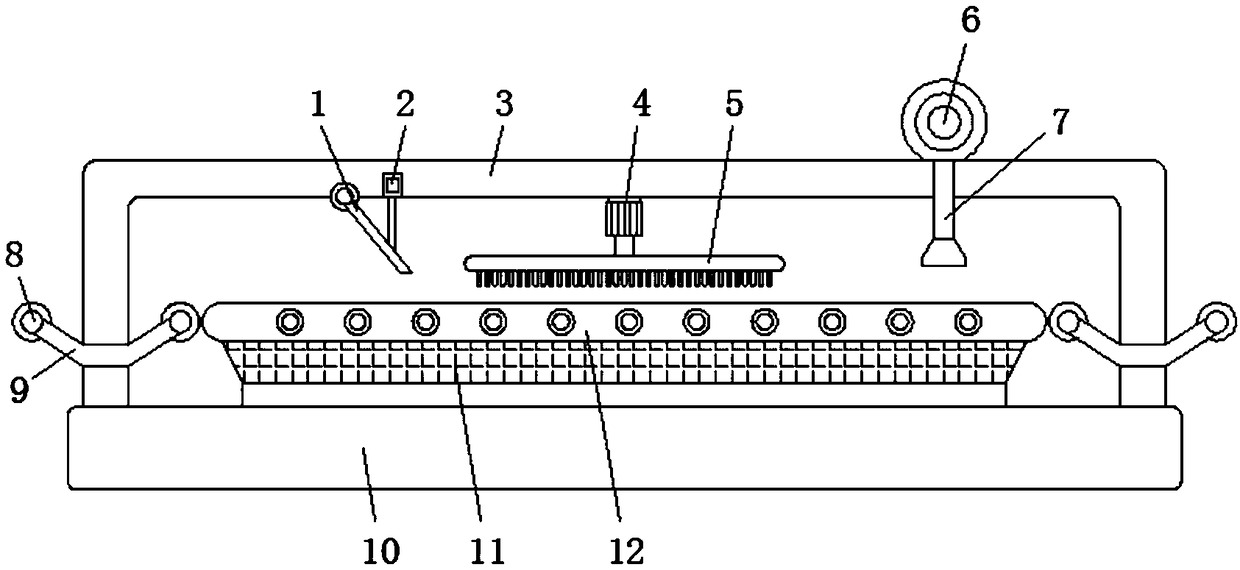

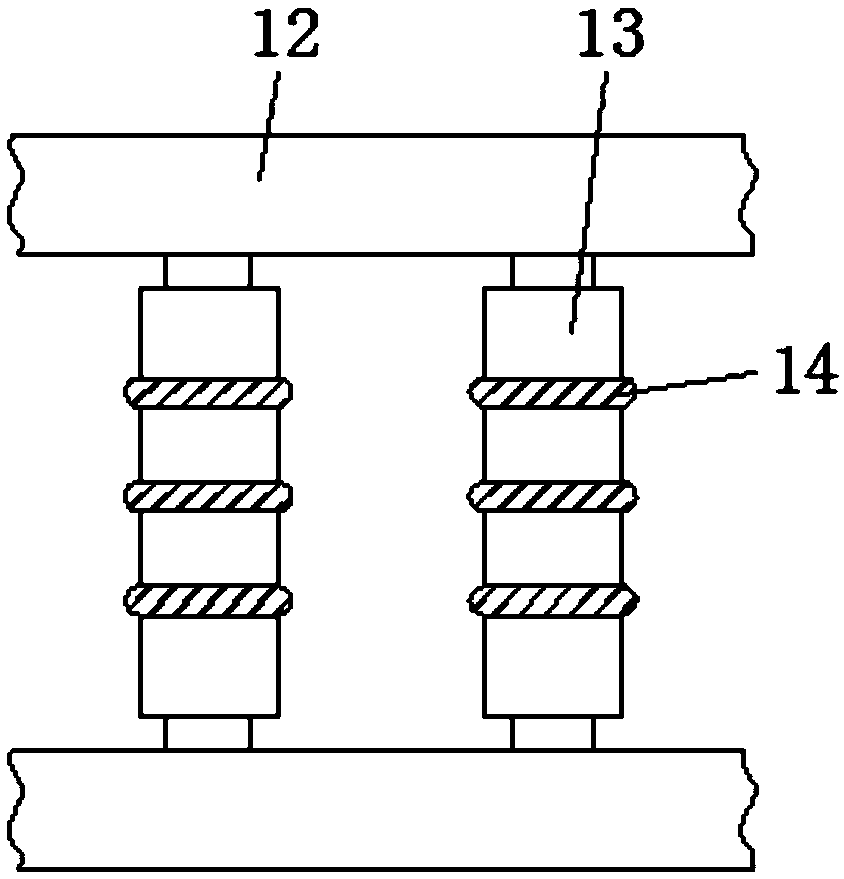

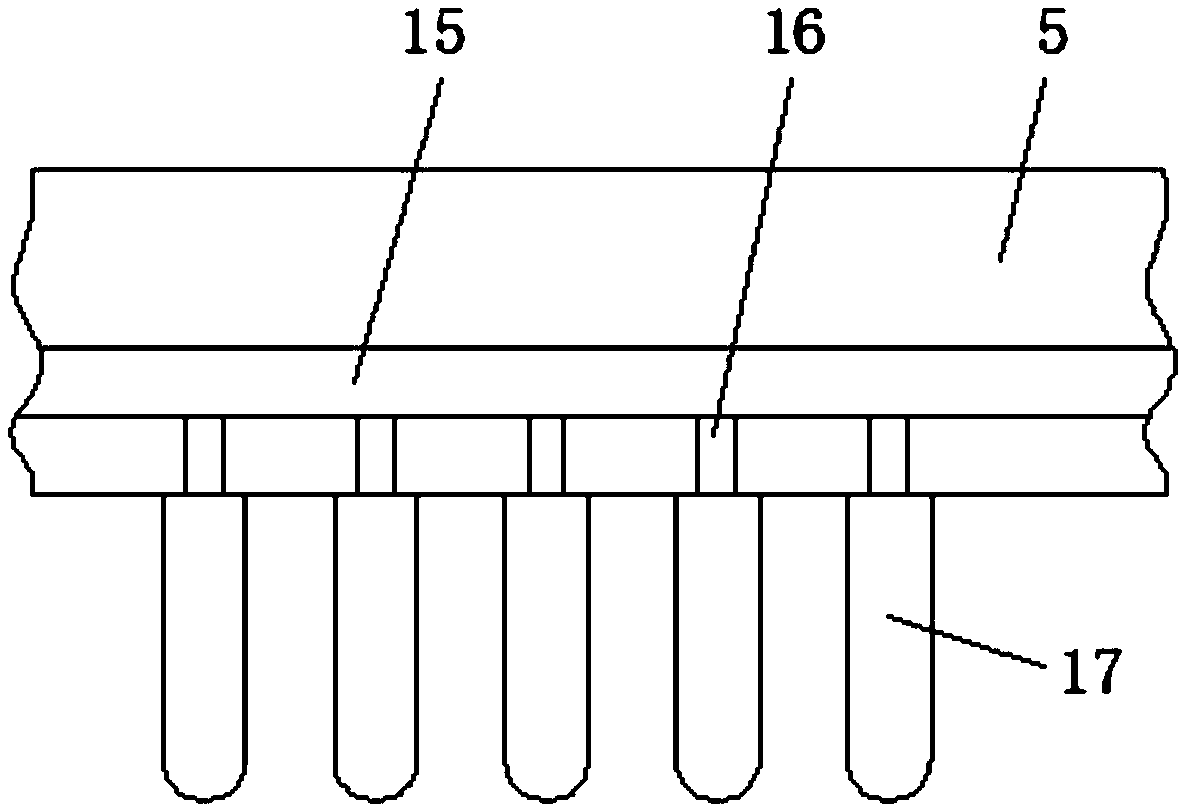

Glass plate conveying device with cleaning function

InactiveCN108689170APlay the role of cushioning and shock absorptionImprove transport safetyCharge manipulationCleaning using toolsRubber ringDrive motor

The invention discloses a glass plate conveying device with a cleaning function. The glass plate conveying device with the cleaning function comprises a base; a recycling bin is welded to the upper surface of the base; a conveying frame is fixed to the top of the recycling bin through bolts; a drive motor is fixed to the center of the lower surface of a supporting frame through bolts; the lower portion of the drive motor is in drive connection with a cleaning brush plate through an output shaft; a water guide pipe is arranged inside the cleaning brush plate; the lower portion of the water guide pipe is connected with a brush rod on the lower surface of the cleaning brush plate through an atomization pipe; one side of the lower surface of the supporting frame is rotationally connected witha dust scraper; a hot-air blower is fixed to the upper surface of one side of the supporting frame through bolts; and the lower portion of the hot-air blower is connected with an air outlet pipe. In the glass plate conveying device with the cleaning function, a soft rubber ring can play a role in buffering and shock absorption for glass plates on a conveying roller, the situation that the surfacesof the glass plates are excessively abraded due to direct contact with the conveying roller is prevented, and the conveying safety of the glass plates is improved.

Owner:ZHENGZHOU AOTUOKELAN MACHINERY EQUIP CO LTD

Pallet-like support base for transport and storage containers for liquids

ActiveUS20120211395A1Improve transport safetyIncrease coefficient of frictionOther accessoriesContainer/bottle contructionPlastic materialsTransport medium

A pallet-like support base for transport and storage containers for liquids includes an inner container of plastics material and an outer jacket of a metal grid or of sheet metal which is adapted to be manipulated by a forklift, a shelf operating system or a similar transport medium, and with a bottom of metal resting on support legs of metal, a middle runner and two outer runners for supporting the inner container which is equipped with a closable filler connection and a drain connection for connection to a drain fitting. The middle runner and the two outer runners of the support base are constructed as wooden runners.

Owner:PROTECHNA SA

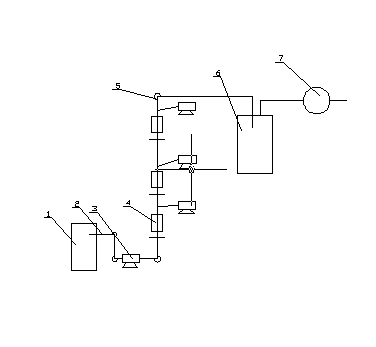

Concentrated acid conveying device

The invention relates to a concentrated acid conveying device which comprises pipes and conveying pumps, wherein the pipes and the conveying pumps are arranged between a concentrated acid storage tank and an elevated tank. Middle storage tanks are arranged between the conveying pumps and the elevated tank at intervals of a certain height and respectively provided with a liquid inlet, a liquid outlet and one conveying pump, and the elevated tank is provided with a vacuumizer. The concentrated acid conveying device reduces pressure of the pipes, prevents the pipes from being damaged easily, and enables concentrated acid to be smoothly conveyed.

Owner:GAOYOU MINGZENG BIOLOGICAL PROD CO LTD

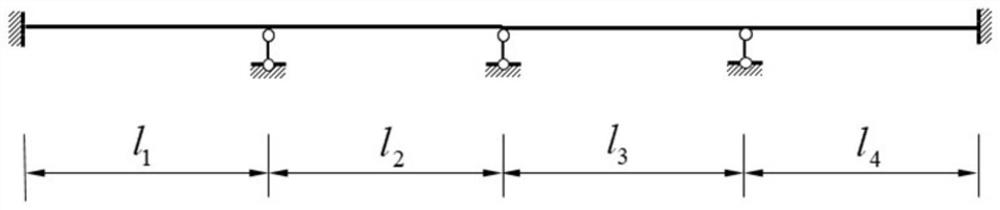

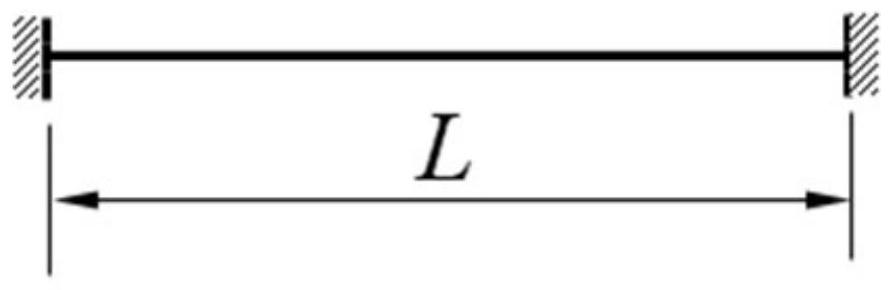

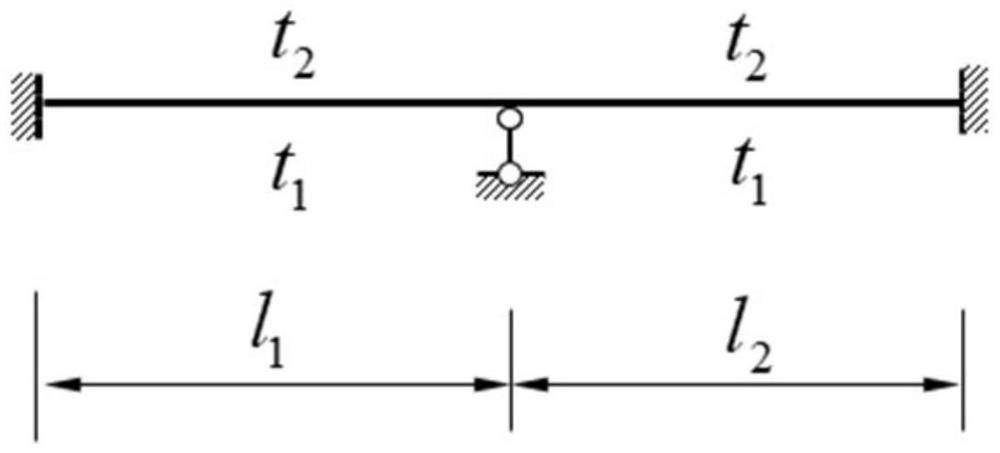

Method for calculating additional load of coal slurry pipeline caused by temperature difference and support displacement

ActiveCN114417228AImprove securityExtend your lifeGeometric CADDesign optimisation/simulationBending momentCoal slurry

The invention provides a method for calculating coal slurry pipeline additional load caused by temperature difference and support displacement, which comprises the following steps of: (1) determining physical parameters of a coal slurry pipeline, and calculating inertia moment of the pipeline; (2) the pipeline is divided into basic structures, and the temperature difference and the bending moment and shear force values of the basic structures under support displacement are calculated; (3) calculating the angular displacement of the integral structure rigid node under the temperature difference and the support displacement, and further calculating the bending moment and the shearing force of the basic structure in the integral structure; and (4) calculating additional normal stress, additional shear stress and additional support load according to the rod end bending moment and shear force caused by the temperature difference and support displacement. According to the method, the temperature difference and the load of the coal slurry pipeline under support displacement can be scientifically calculated, and a theoretical basis is provided for optimizing the arrangement of the coal slurry pipeline and improving the conveying safety of the coal slurry.

Owner:WUHAN DESIGN & RES INST OF CHINA COALTECH & ENG GROUP

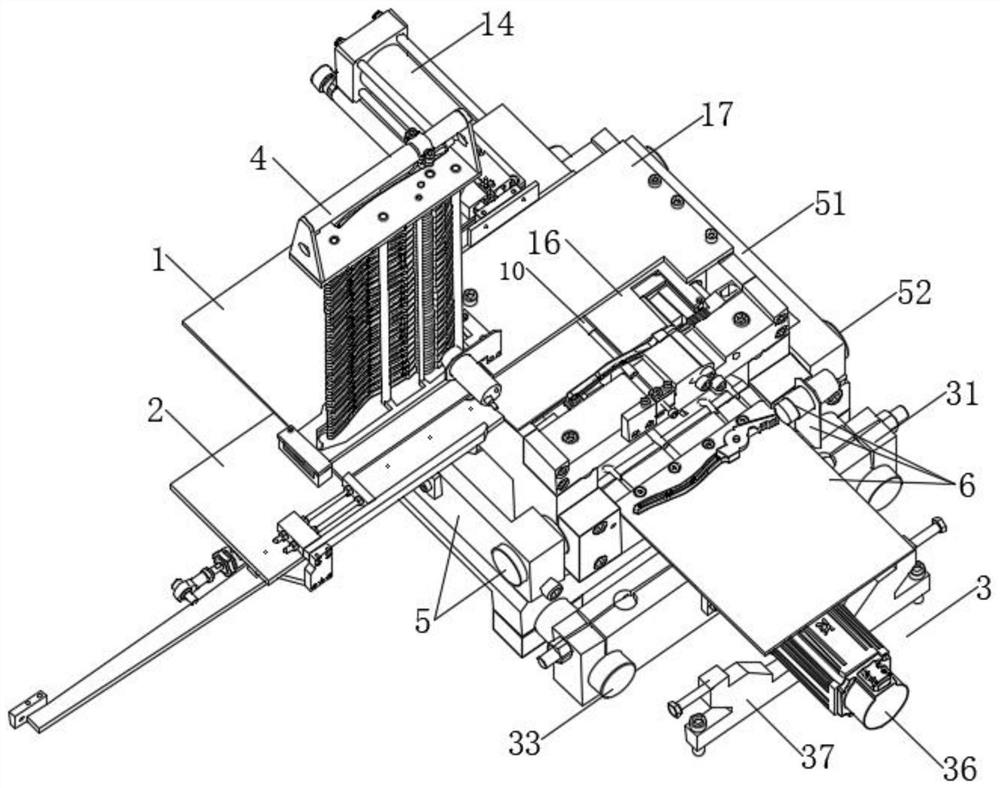

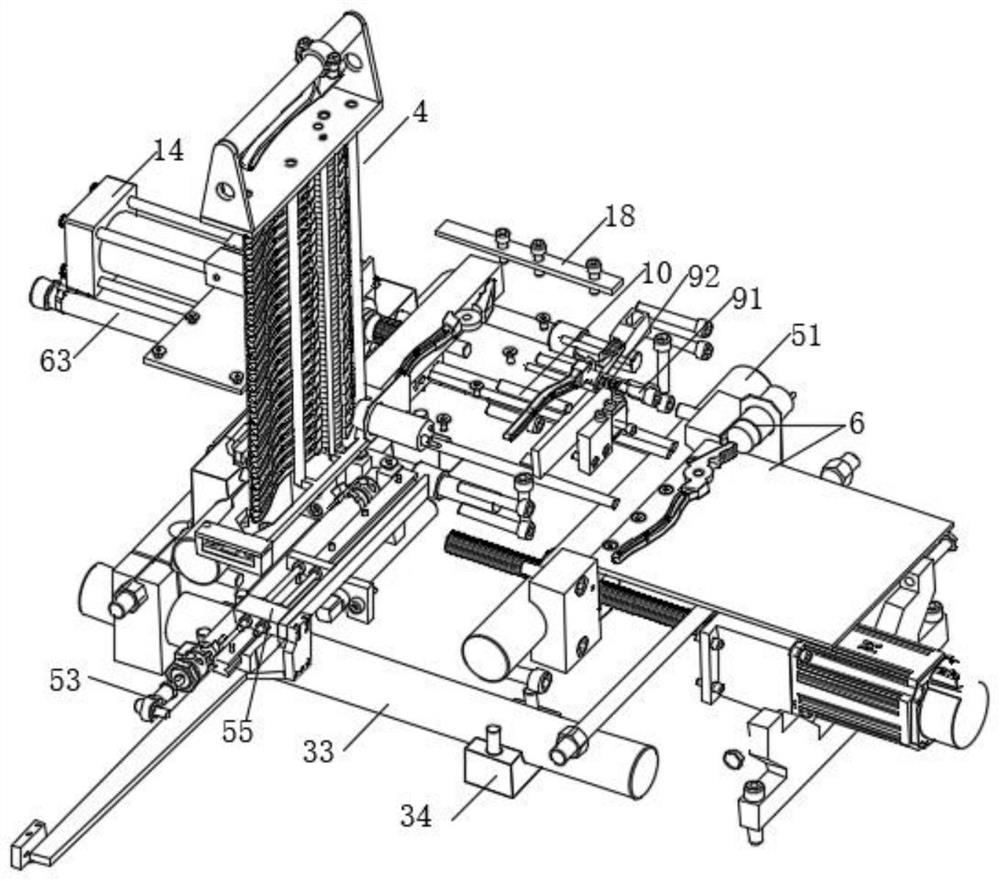

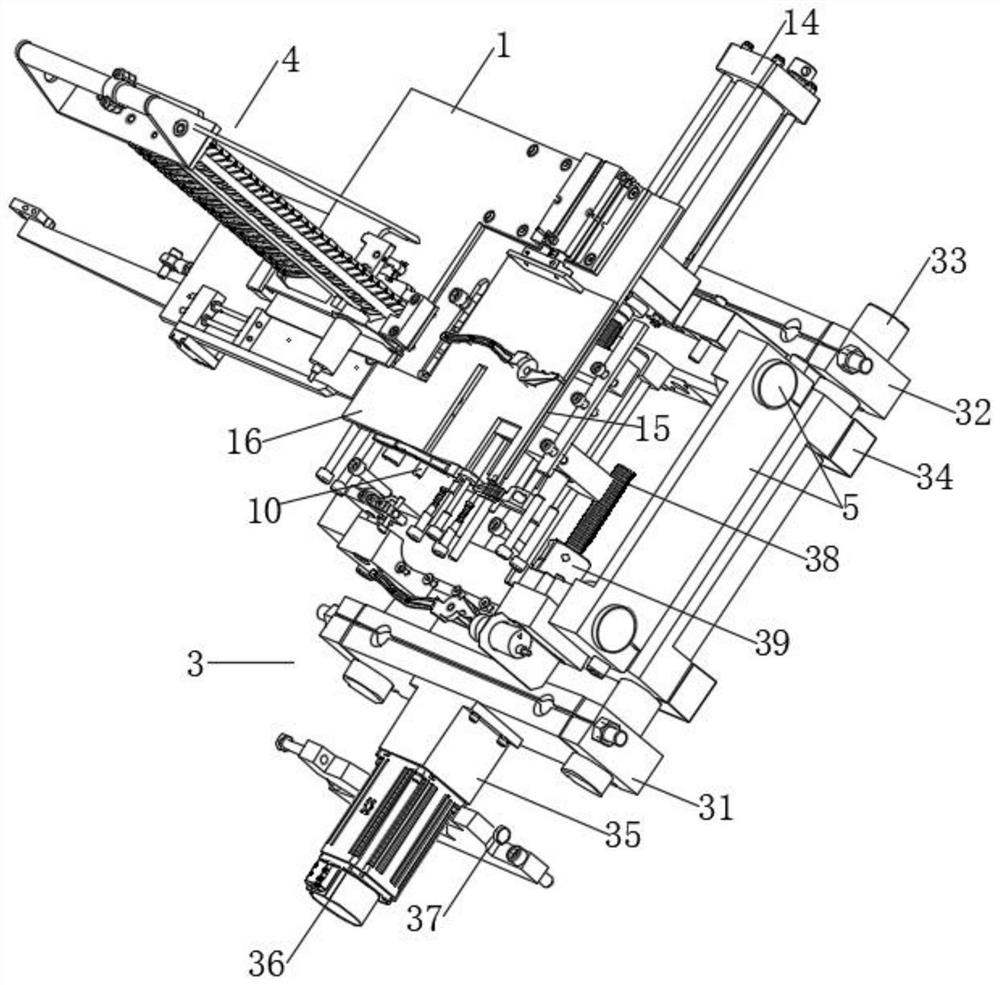

Automatic conveying device for clamp piece machining

InactiveCN112158582ARealize automatic unloadingRealize automatic conveying operationControl devices for conveyorsMachining processEngineering

The invention discloses an automatic conveying device for clamp piece machining. The automatic conveying device for clamp piece machining comprises a manual discharging device, a first-stage moving seat, a material collecting device, a second-stage moving seat and a discharging mechanism, wherein a feeding bottom plate is installed on one side of the manual discharging device; the first-stage moving seat is arranged below the manual discharging device; the material collecting device is arranged at the top of the manual discharging device; the second-stage moving seat is arranged at the top ofthe first-stage moving seat; a discharging mechanism is arranged on the side, away from the material collecting device, of the second-stage moving seat; an integrated fixed clamping block is fixedly installed on the side, close to the discharging mechanism, of the top of the second-stage moving seat; and a first workpiece position leaning piece and a second workpiece position leaning piece are fixedly installed on the side, close to the discharging mechanism, of the integrated fixed clamping block; The automatic conveying device for clamp piece machining has the beneficial effects that automatic discharging, feeding, clamping machining and discharging, and clamp piece machining automatic conveying operation in the clamp piece machining process are achieved, the clamp piece machining efficiency is improved, the labor cost is reduced, the conveying safety is higher, an induction assembly is used for discharging and discharging induction, and the clamp piece conveying stability is improved.

Owner:湖南精专自动化技术有限公司

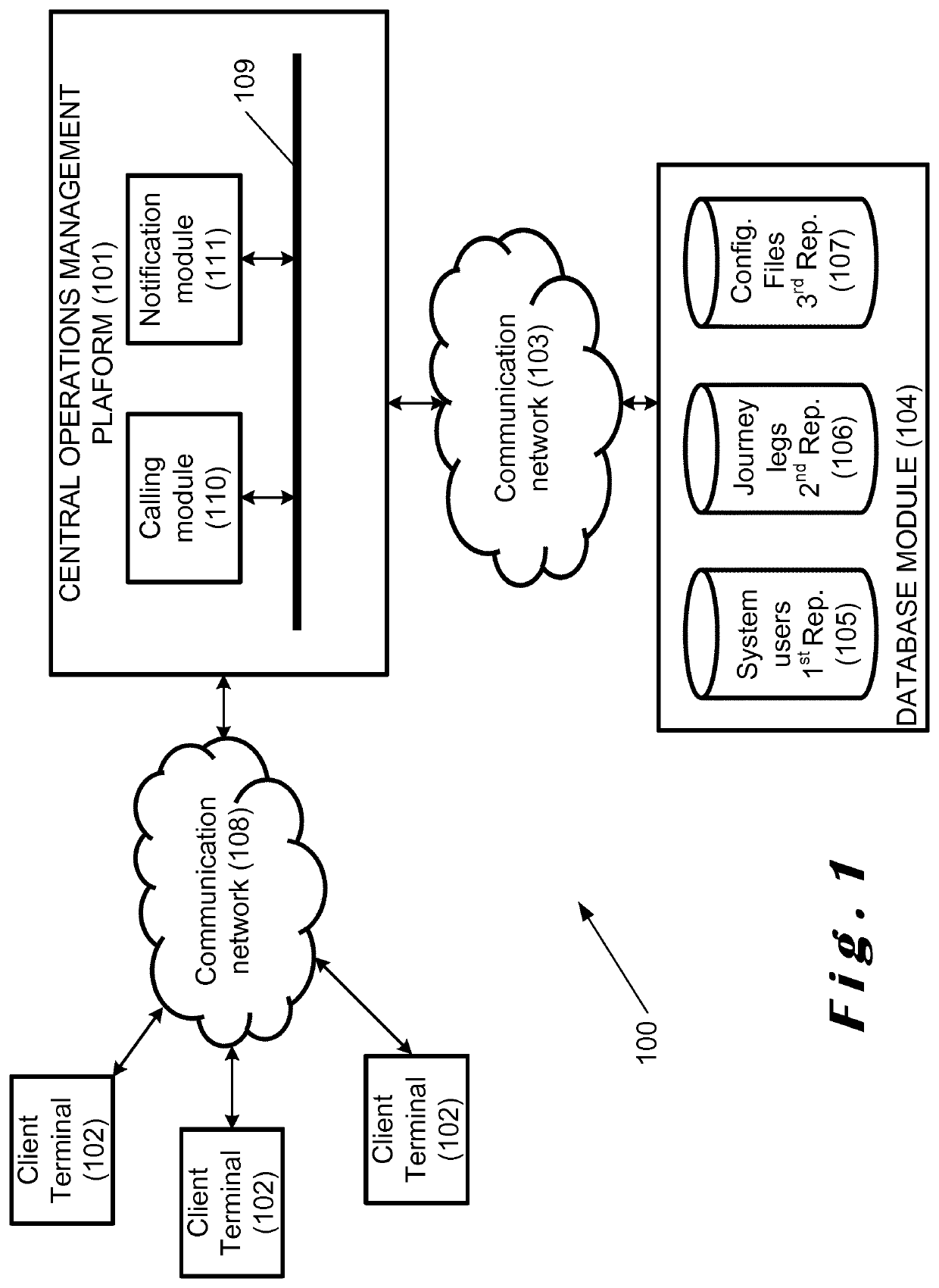

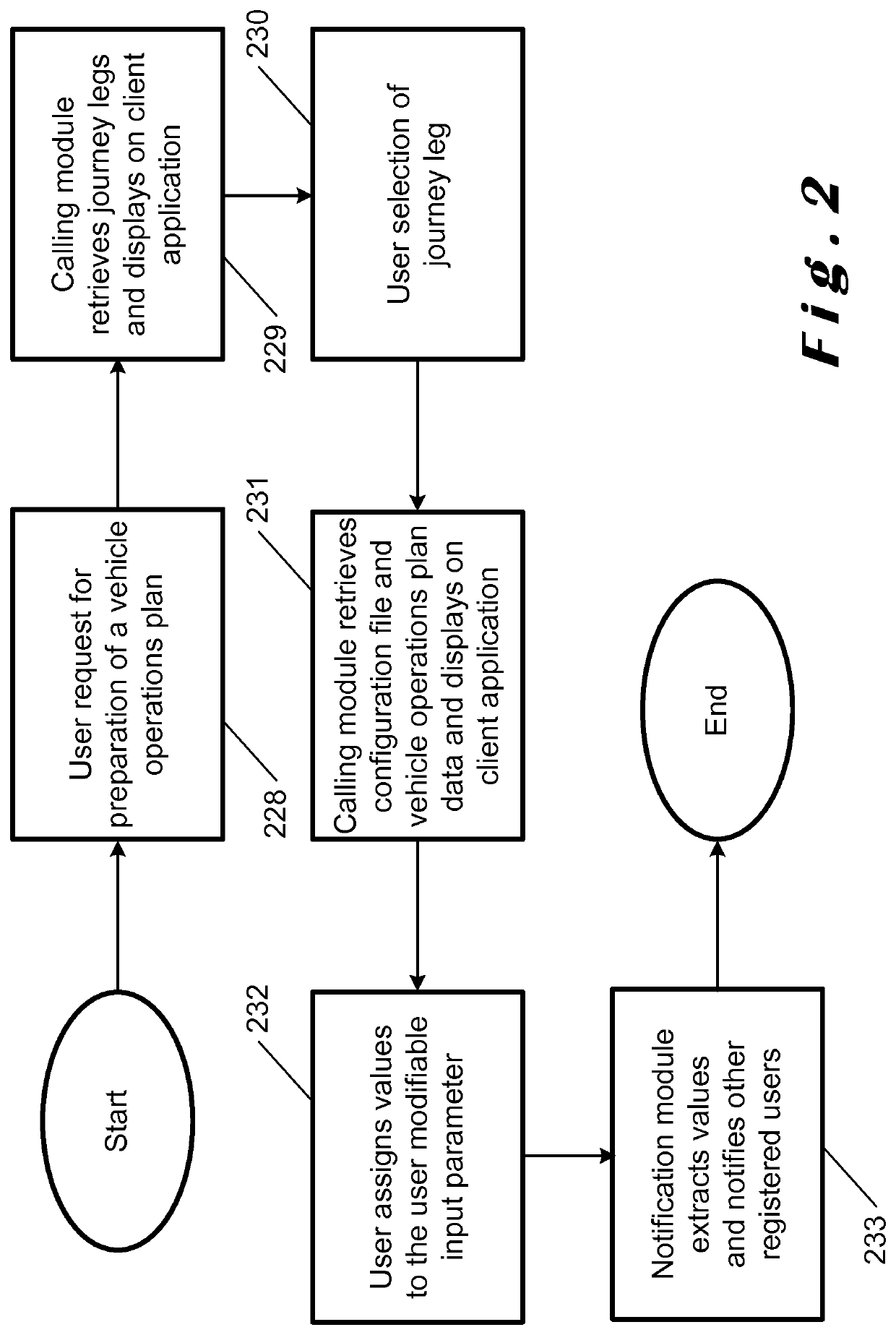

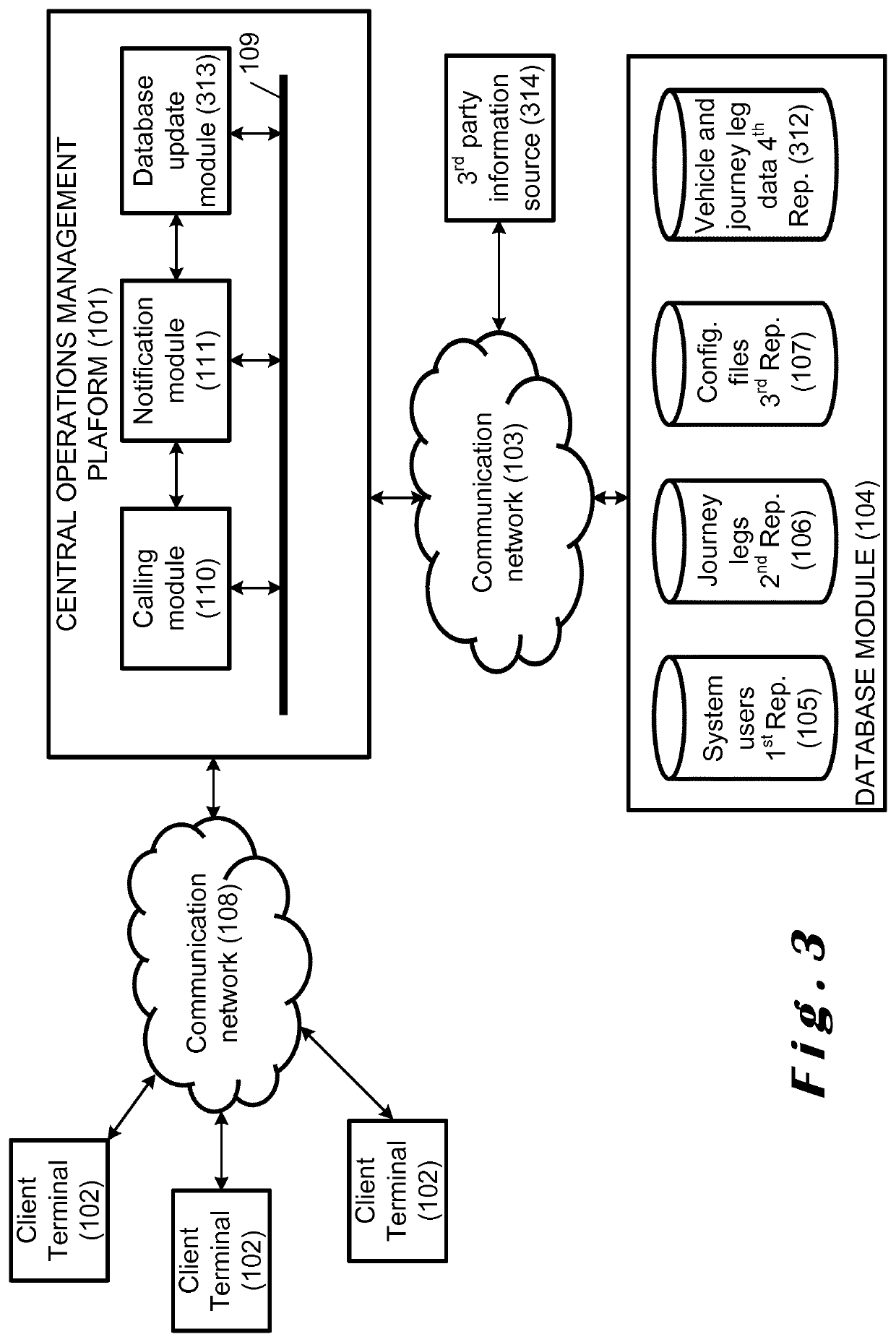

A system and a method for managing the operations of a commercial transportation vehicle

InactiveUS20210065120A1Improve transport safetyCompromising security and reliability of systemTransportation facility accessOffice automationDatabaseReal-time computing

A system for managing the operations of a commercial transport vehicle for a selected journey leg, wherein a qualified registered user can prepare a vehicle operations plan pertaining to a selected journey leg through a vehicle operations planning tool displayed via a GUI running on a client application based on at least one configuration file associated with the qualified registered user's qualification type and the selected journey leg retrieved by a calling module. The system further comprises a notification module configured for extracting the values assigned to the vehicle operations plan by the qualified registered user and further configured for selectively notifying qualified registered users linked to the selected journey leg and concerned with the extracted values.

Owner:AVIOVISION

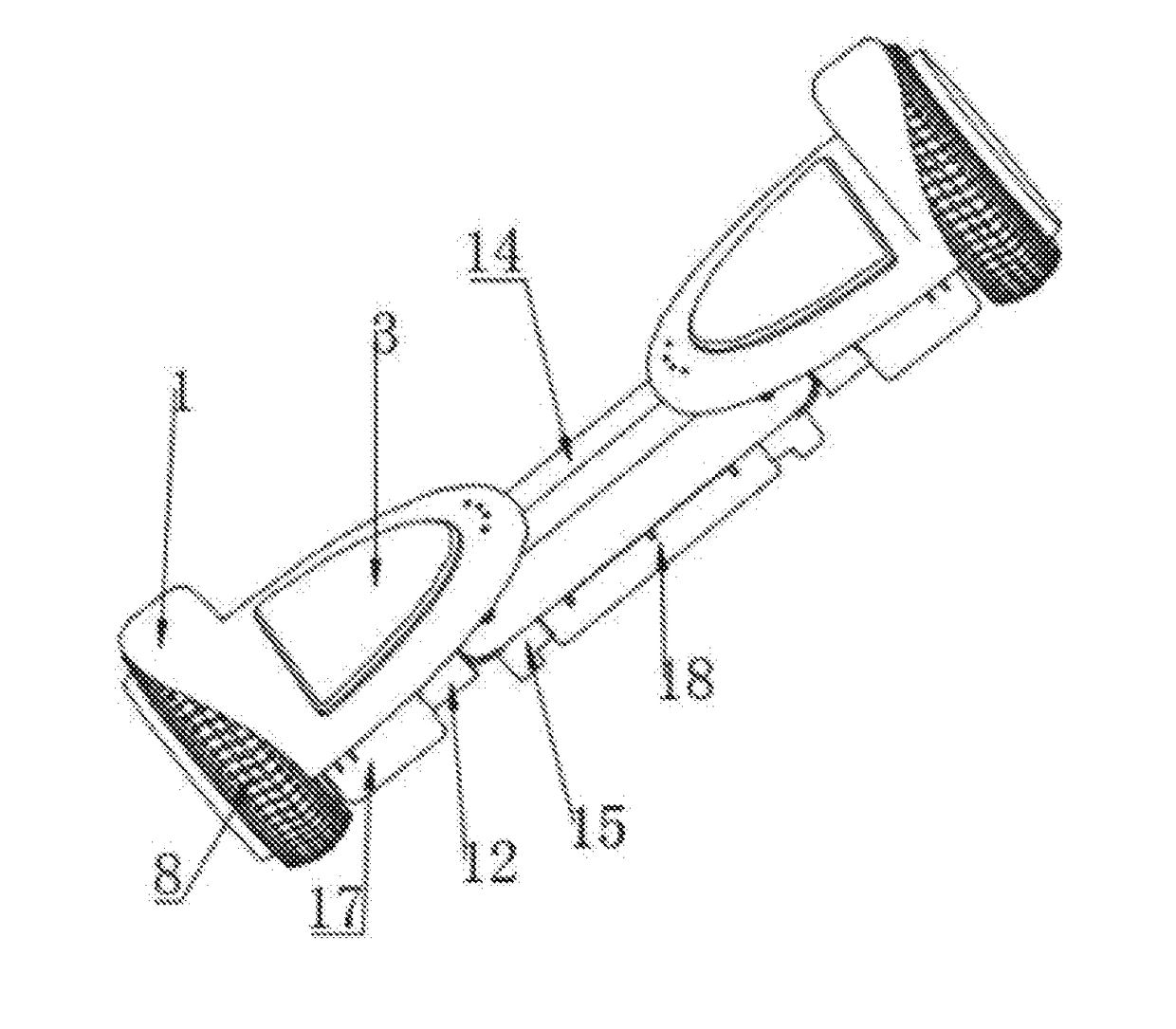

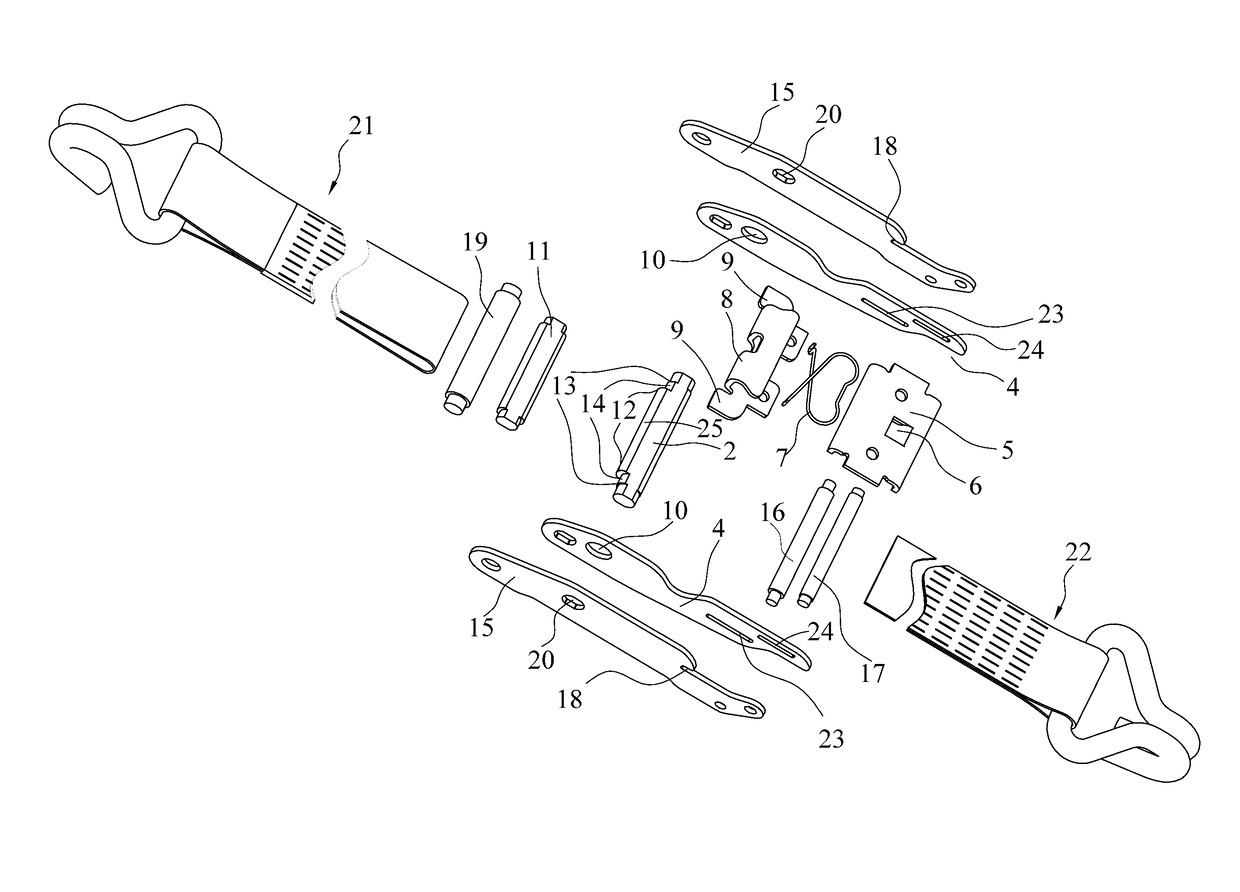

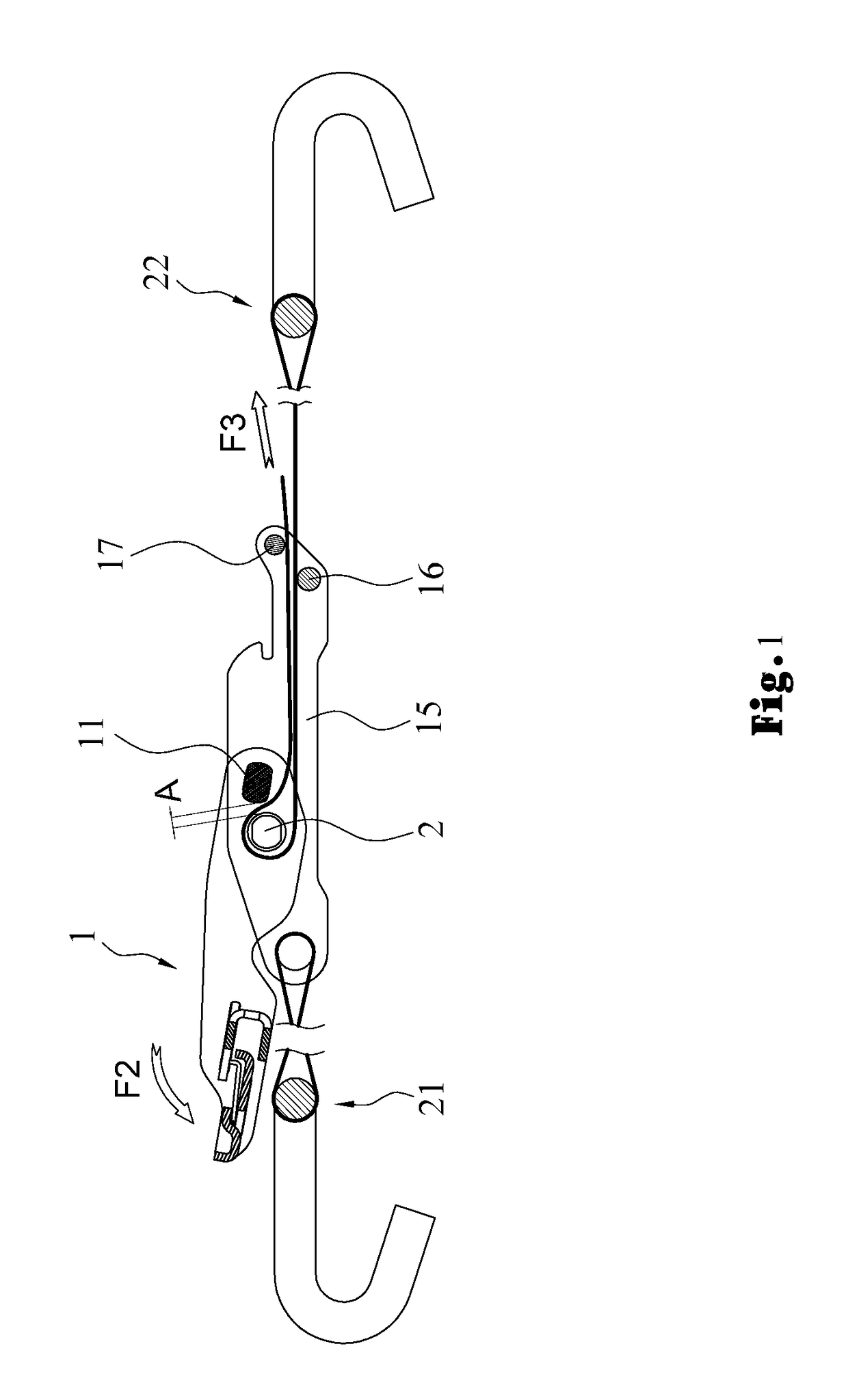

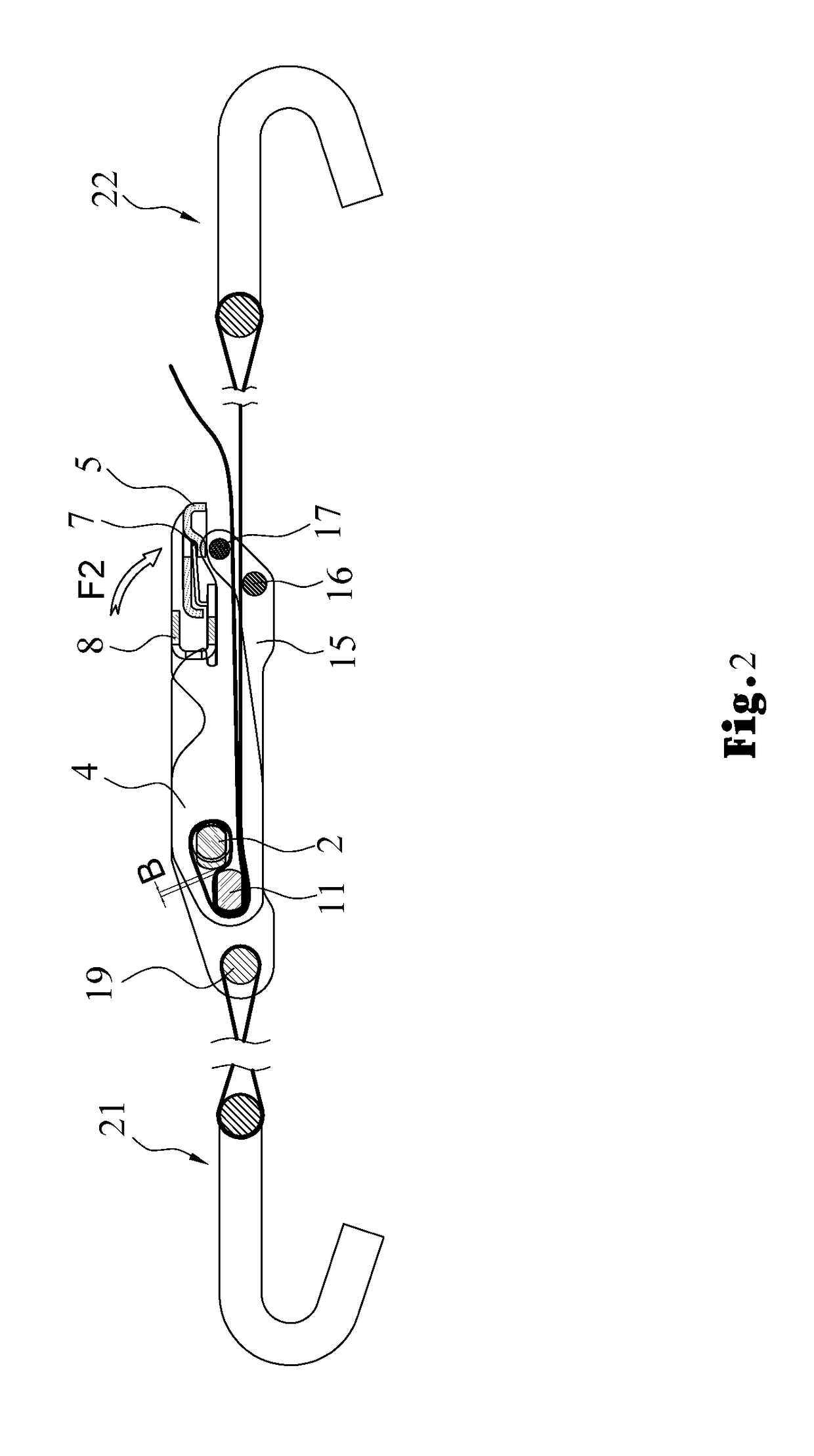

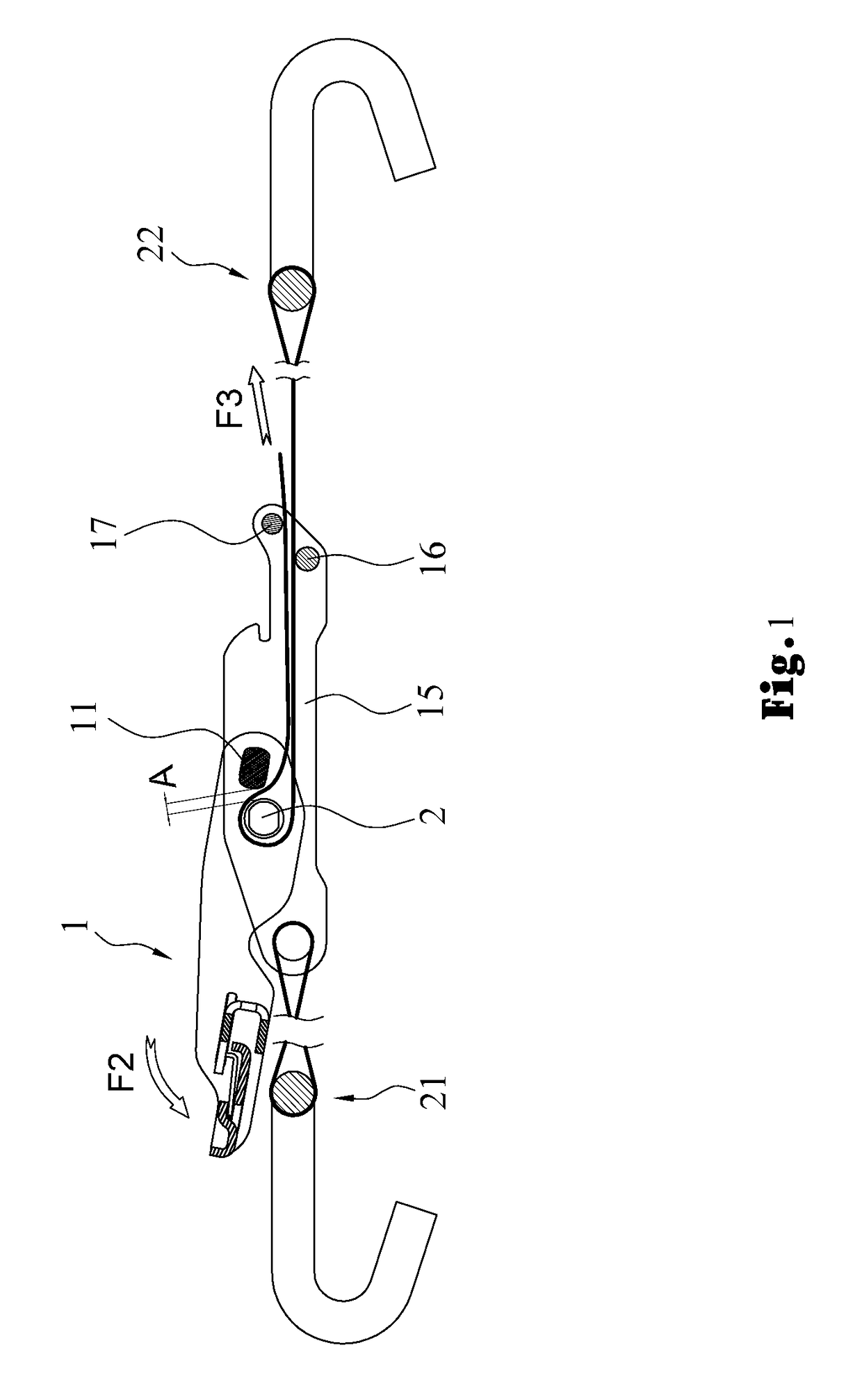

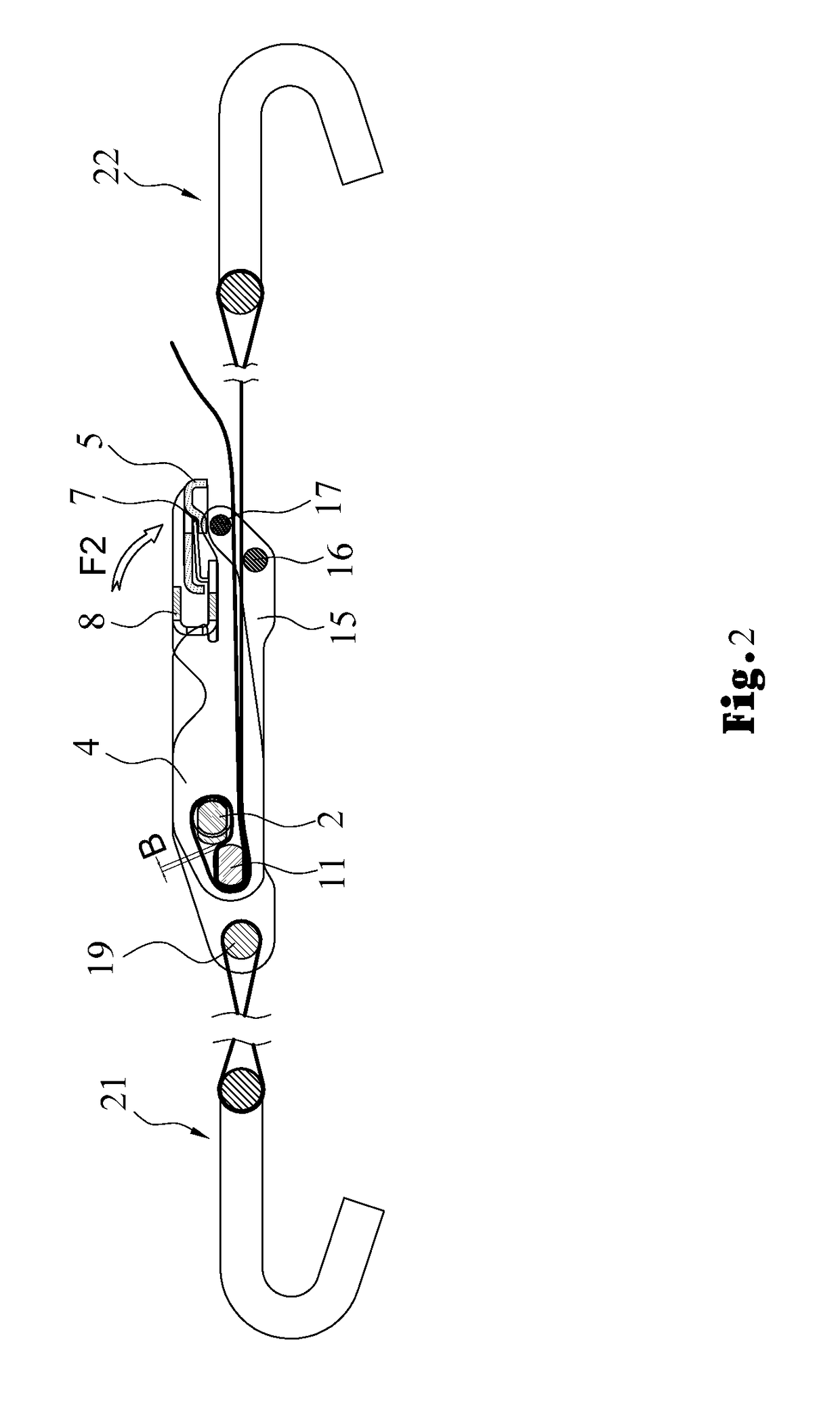

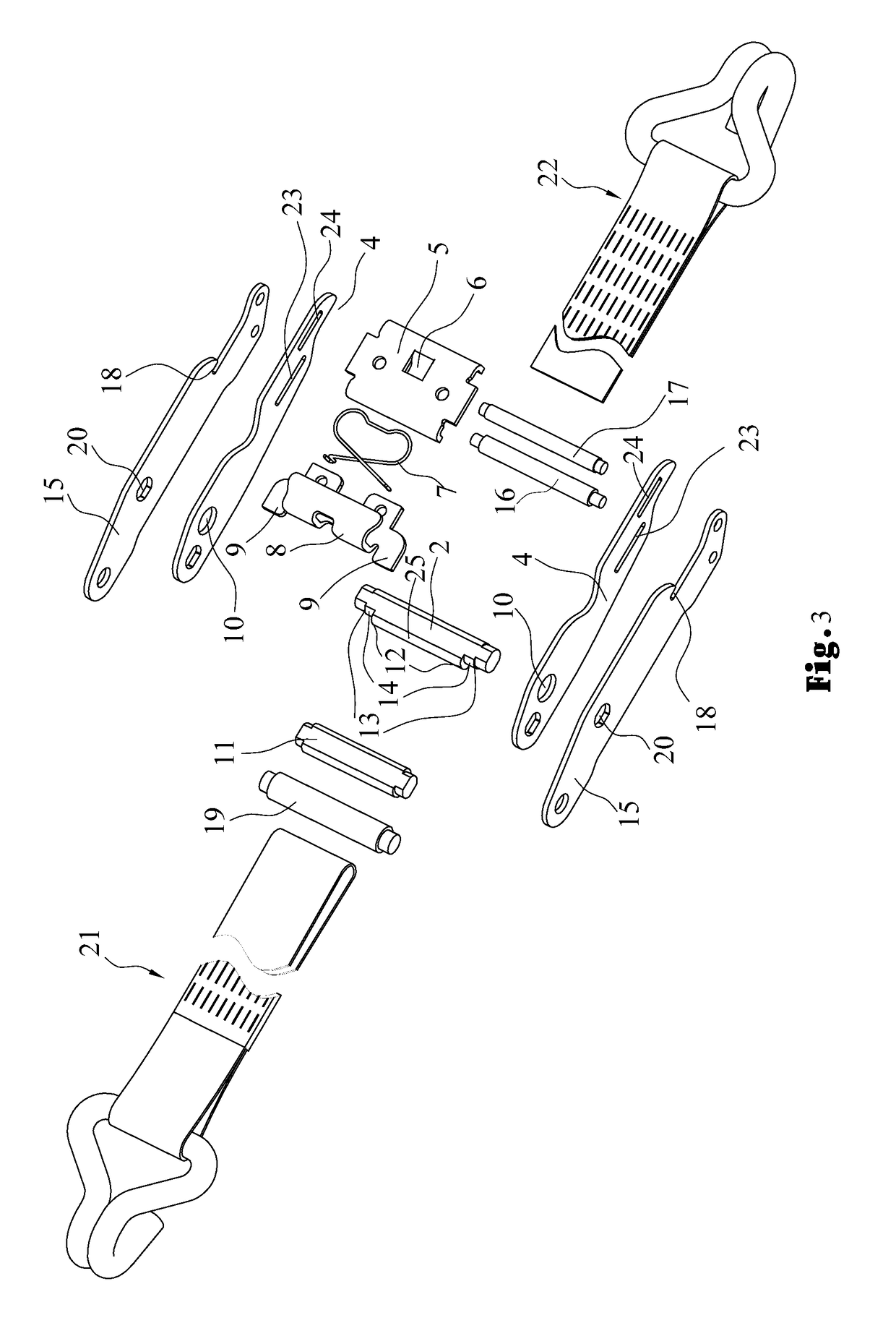

Anti-slip Safety Tensioning Device for Automobile

ActiveUS20180194269A1Reduce gapSecurity tensionFilament handlingLoad securingEngineeringMechanical engineering

An anti-slip safety tensioning device for automobile, comprises a driving handle assembly, an eccentric shaft, a support assembly, a long band and a short band; wherein, the driving handle assembly is located between a pair of support lateral plates of the support assembly, and can be rotatable relative to the eccentric shaft; and when the driving handle assembly is folded, the eccentric shaft is located on a rear side of the top shaft and the eccentric bulge of the eccentric shaft faces the top shaft; the long band having a free end wrapped around the eccentric shaft, and the free end passes through the gap between the eccentric shaft and the top shaft. When in unfolded state, there is a largest gap between the top shaft and the eccentric shaft.

Owner:NINGBO XULI METAL PROD

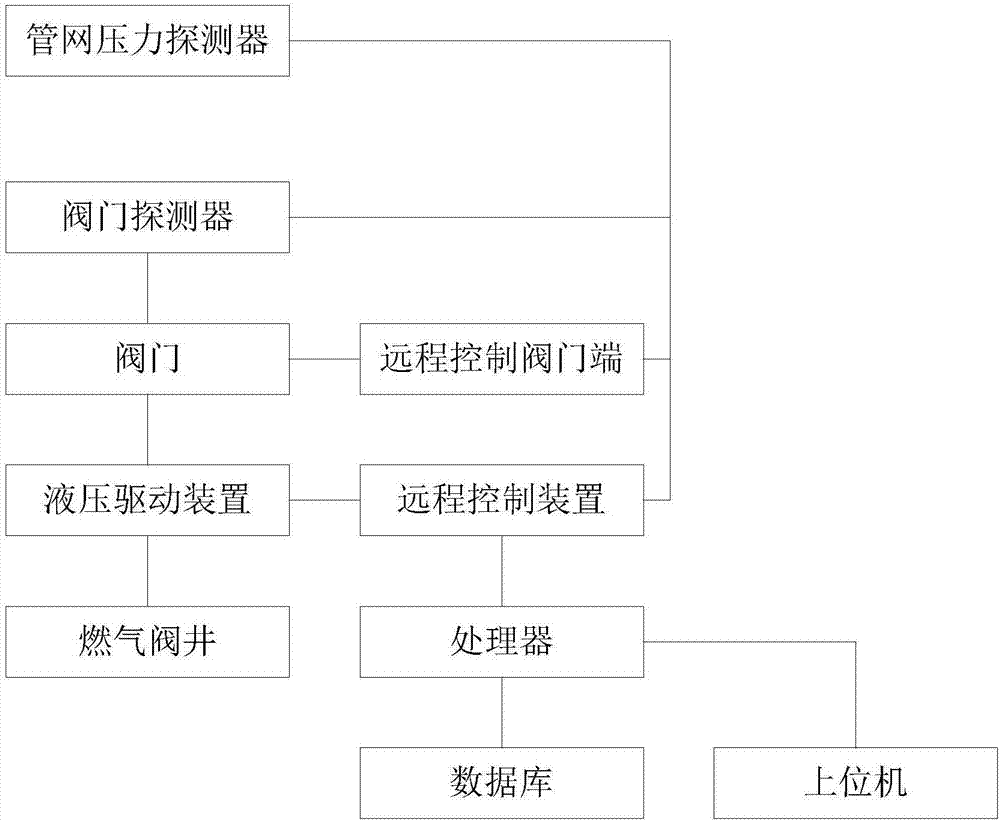

Remote safety monitoring system based on natural gas

InactiveCN107132800AQuick responseImprove securityProgramme controlTransmission systemsEngineeringNatural gas

The invention discloses a remote safety monitoring system based on natural gas. The remote safety monitoring system comprises a gas valve pit, wherein a valve and a hydraulic drive device are connected in the gas valve pit through a pipeline. The remote safety monitoring system further comprises a valve detector, a remote control valve end, a remote control device, a processor, a database and an upper computer, wherein the valve detector is connected with the valve and acquires and sends real-time state information of the valve to the processor, the processor receives the state information of the valve detector, retrieves database comparison, sends adjustment information to the remote control valve end and the remote control device and simultaneously sends the state information to the upper computer. The database stores reserved standard data. The remote control valve end wirelessly controls valve turning on and off, and the remote control device wirelessly controls the hydraulic drive device. The remote safety monitoring system further comprises a pipe network pressure detector for detecting pressure state information of the pipeline and sending the information to the processor in real time.

Owner:四川云一达科技有限公司

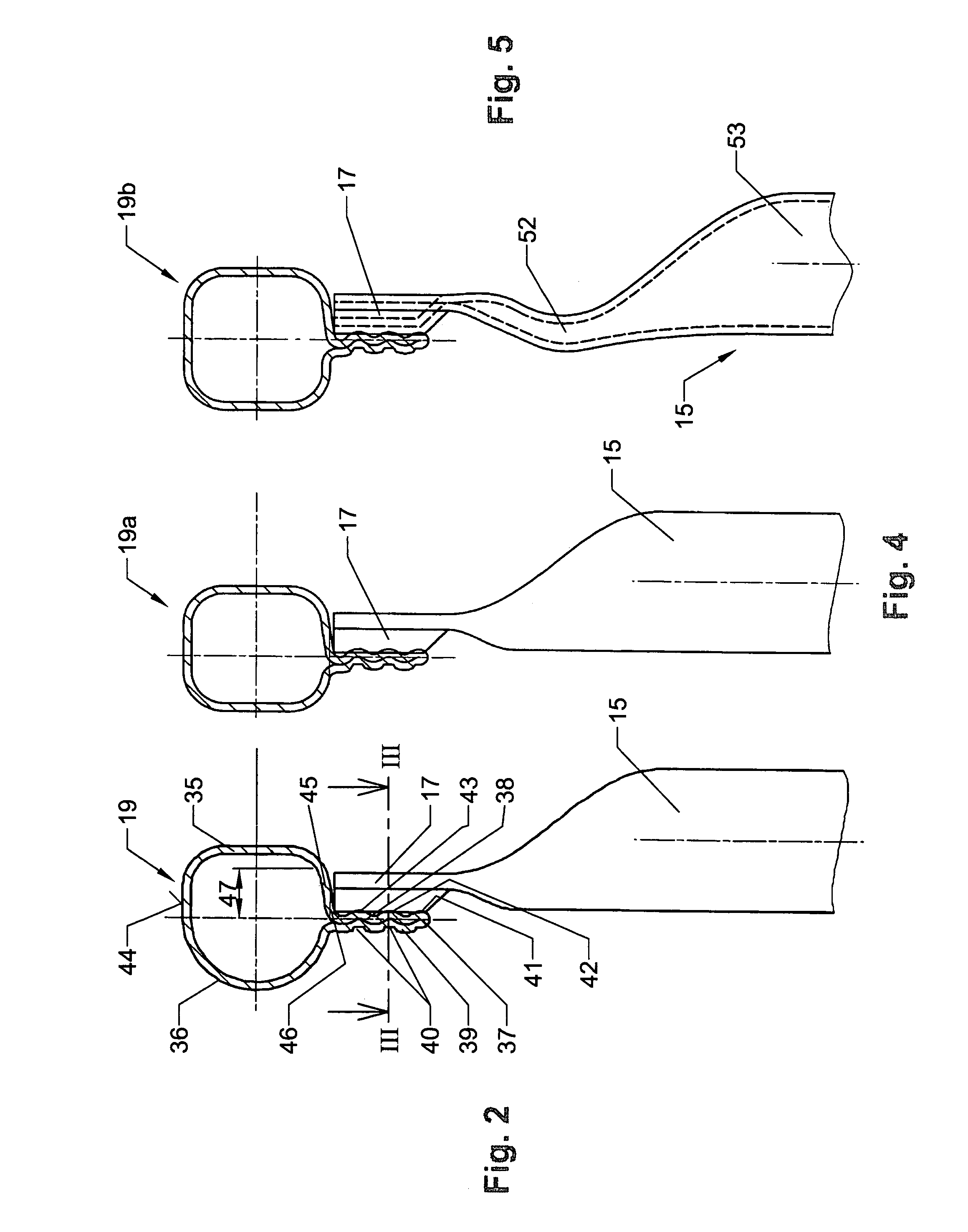

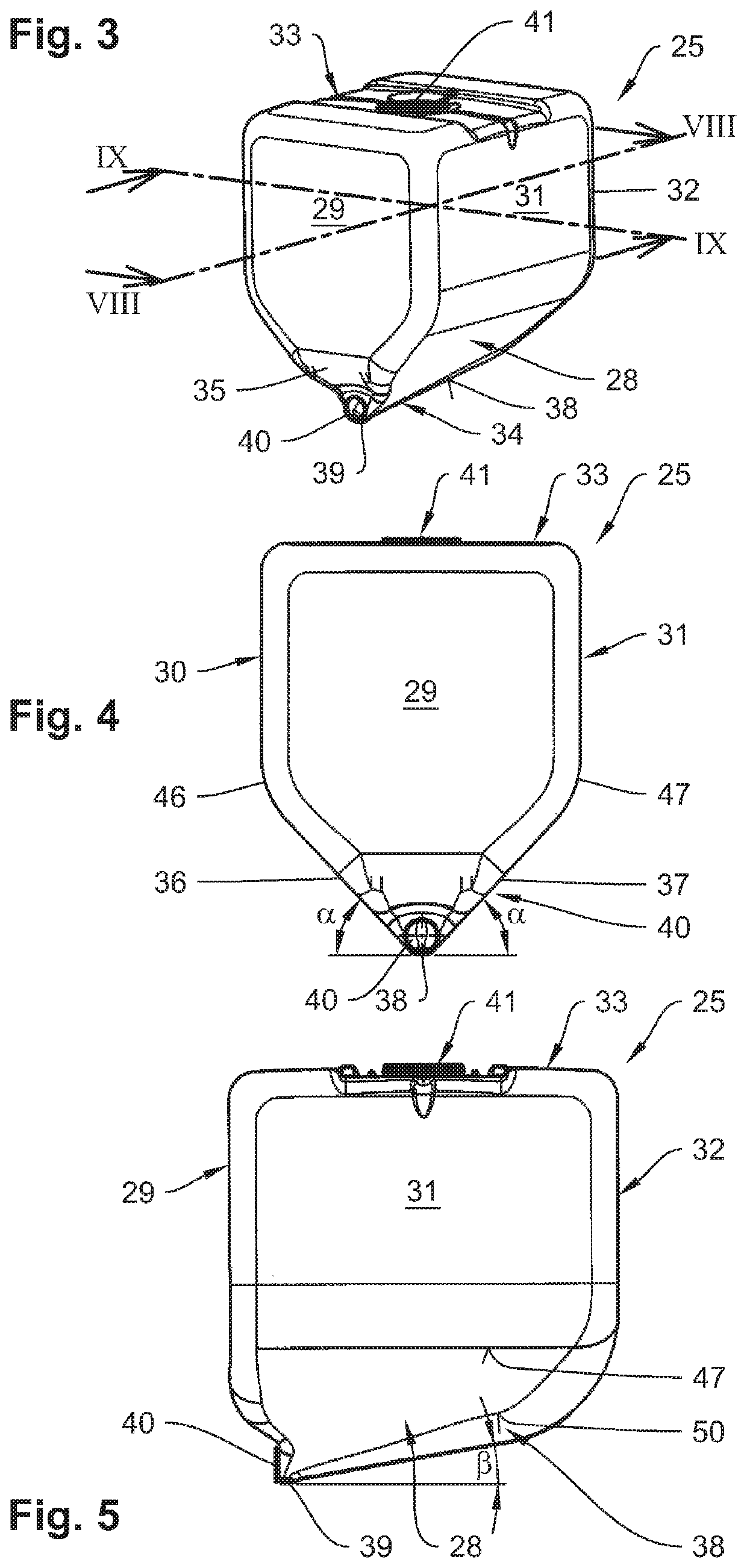

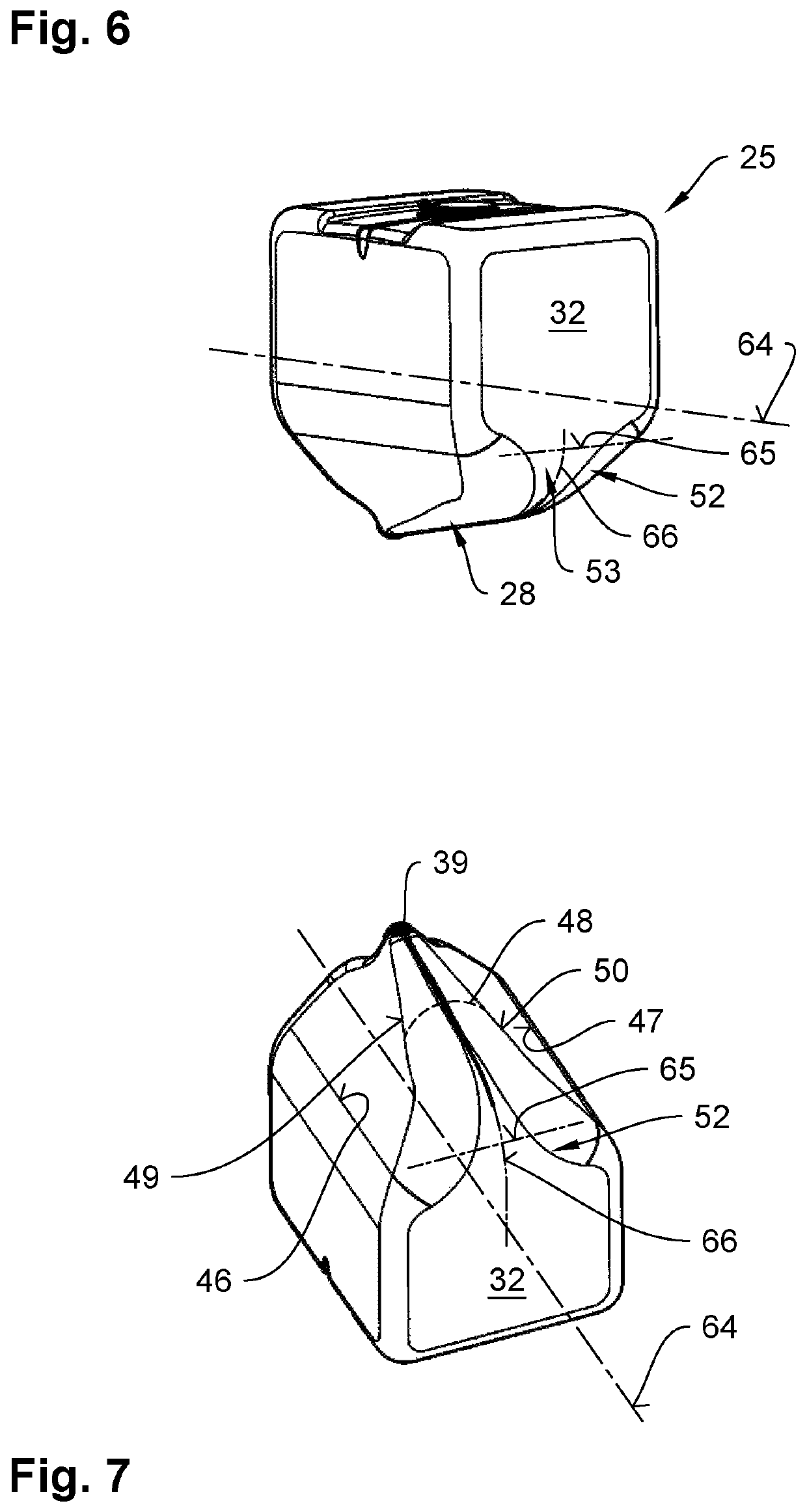

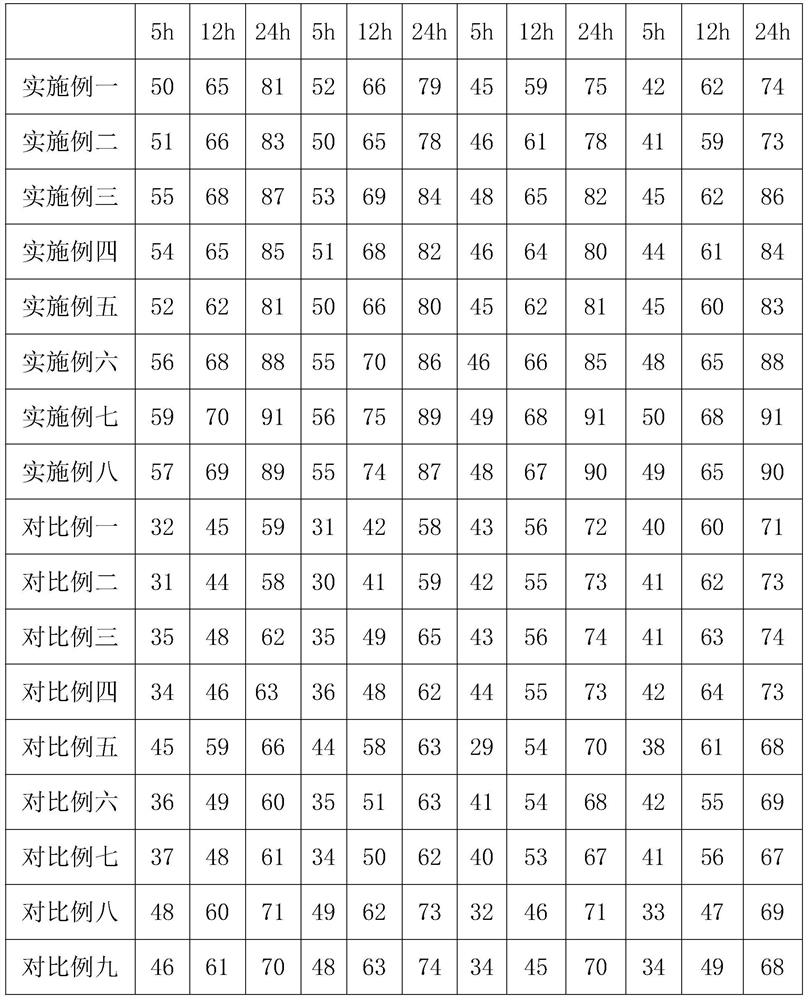

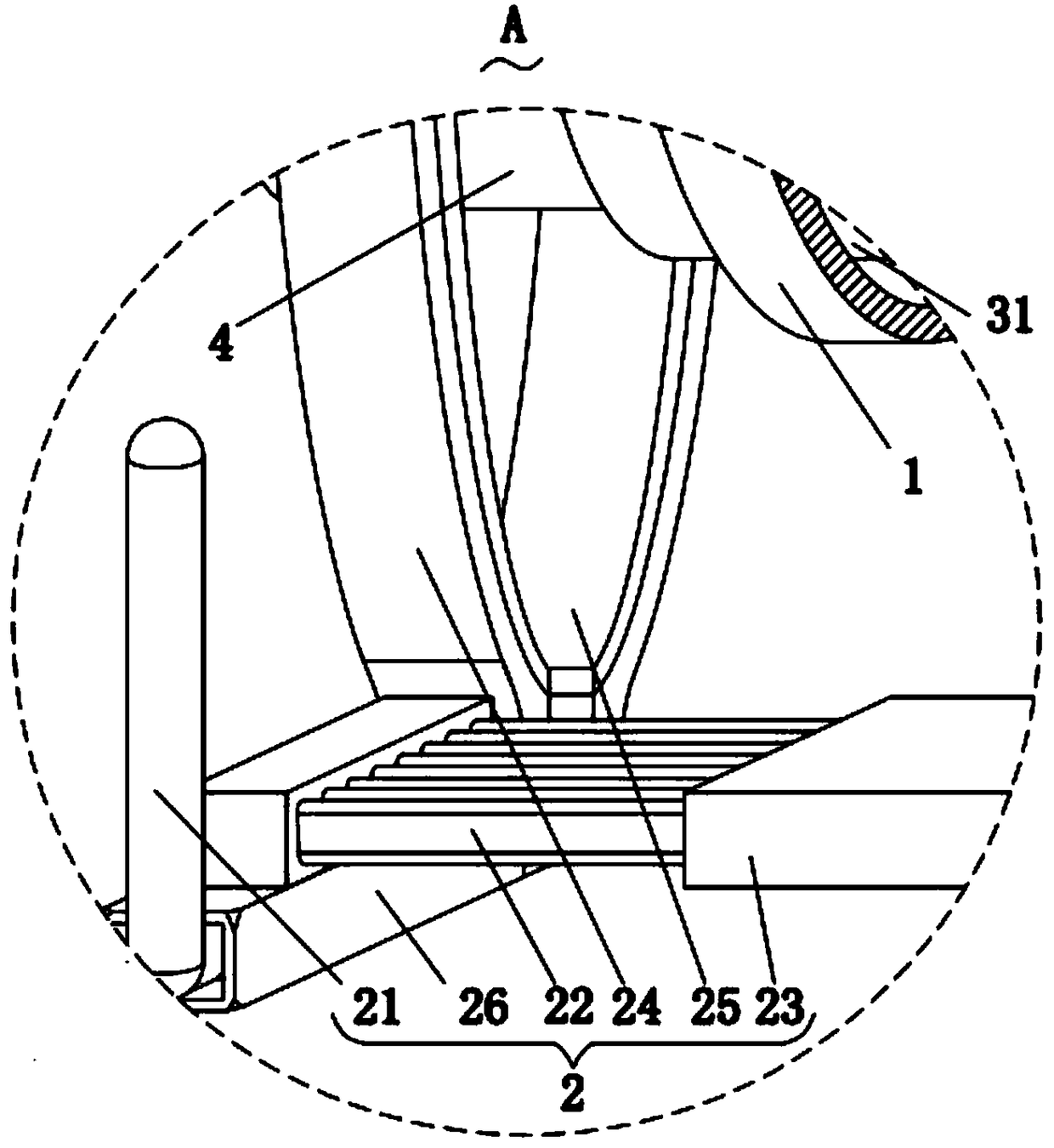

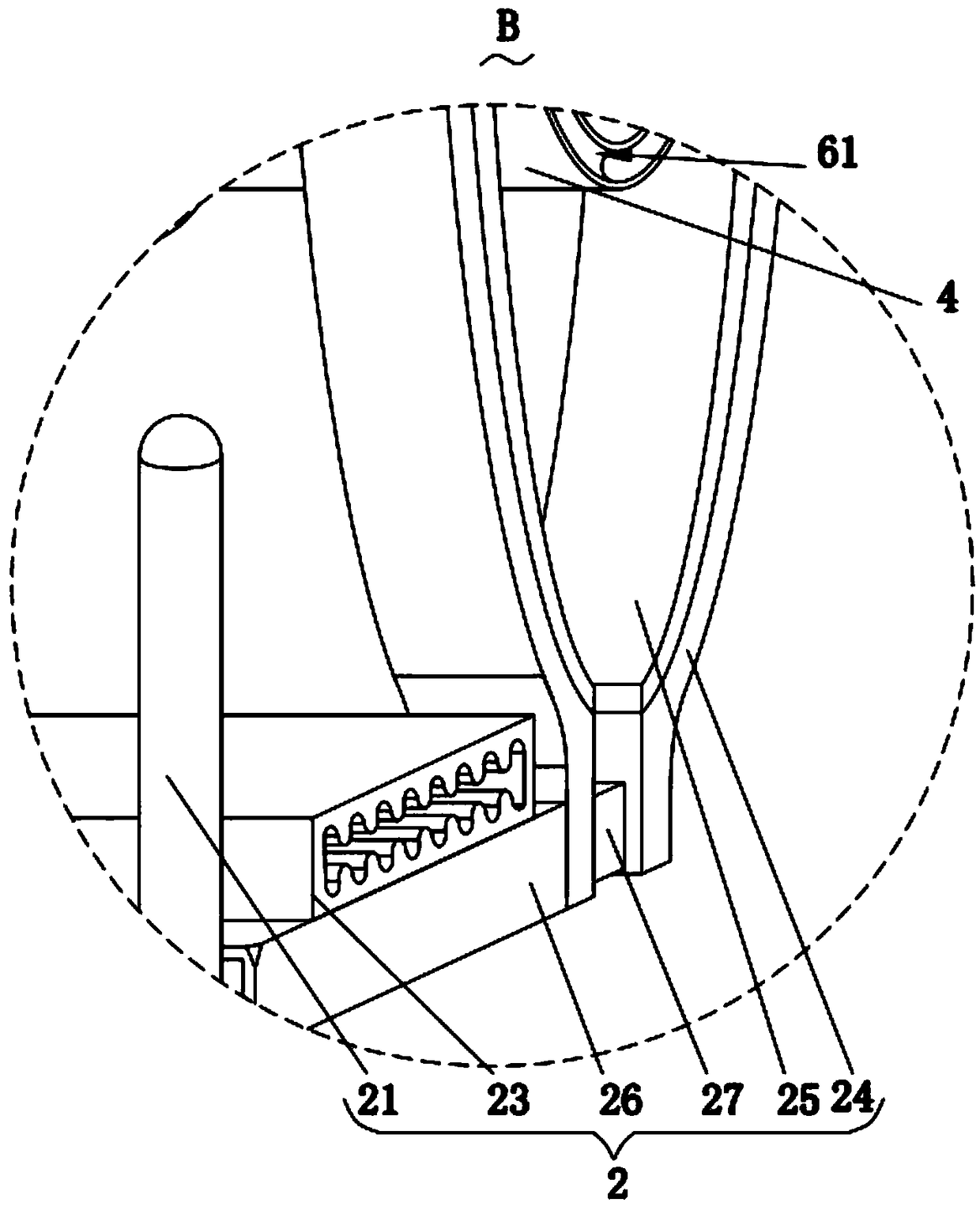

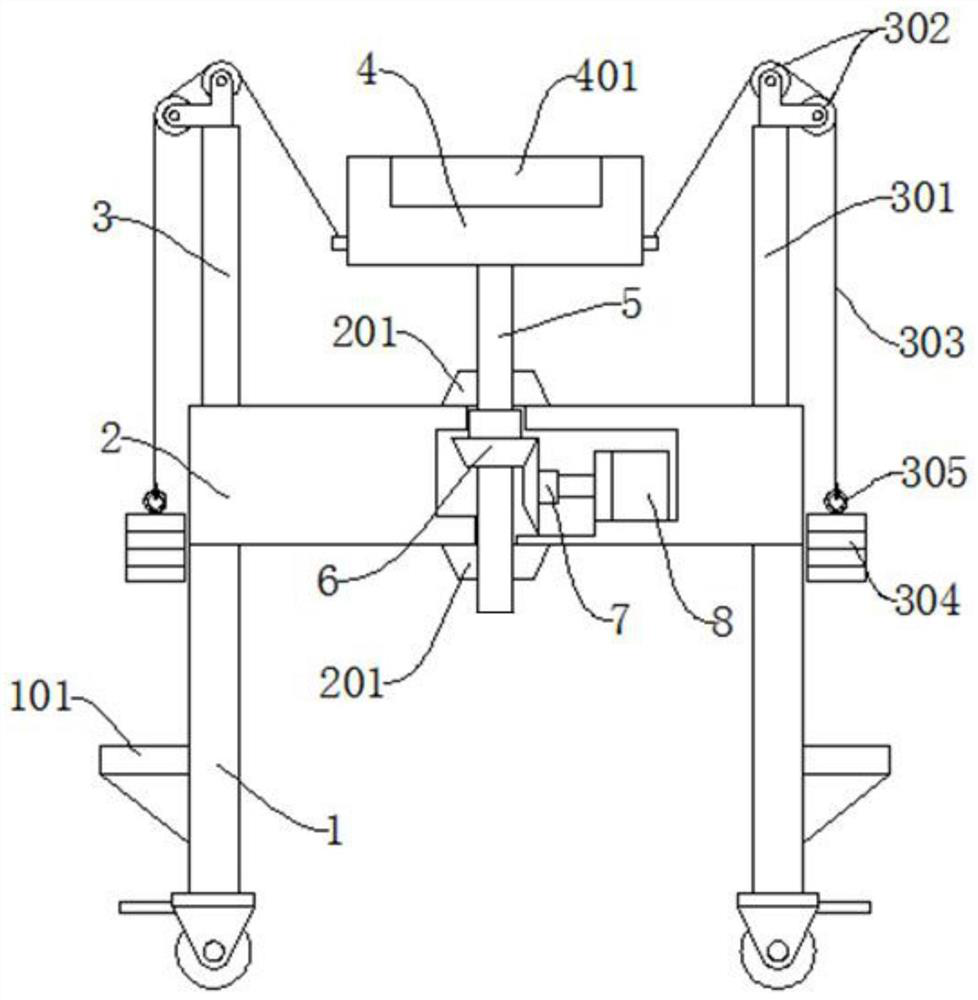

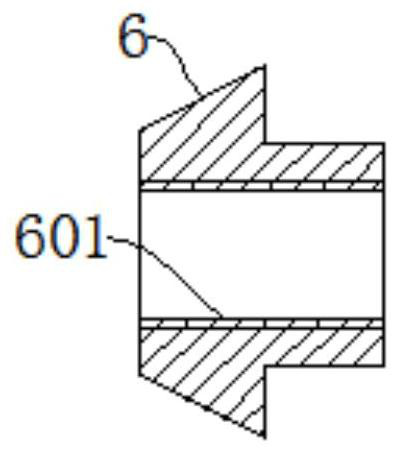

Inner container made of plastic and transport and storage container for liquids comprising such an inner container

ActiveUS10773871B2Improve transport safetyGood effectMixing methodsRotary stirring mixersMechanicsPallet

An inner plastic liquid container (25) includes a filling neck (41) in an upper wall (33) for filling the inner container and a front side outlet neck (40) for an outlet armature. A lower wall (28) interconnecting two side walls (30, 31), a rear wall (32) and a front wall (29) supports the container on a transport pallet (21) pallet base (26), which has an outer mantle (24) for receiving the container. The outlet neck is at a hopper bottom (39) of an outlet hopper (34) in the lower bottom wall. The outlet hopper has a front hopper wall (35) and inclined lateral hopper walls (36, 37) that are arranged at a hopper angle and each extend from a keel-shaped hopper base (38) to a lower edge (46, 47) of a side wall. A keel line (63) rises at another hopper angle from an outlet neck toward the rear wall.

Owner:PROTECHNA SA

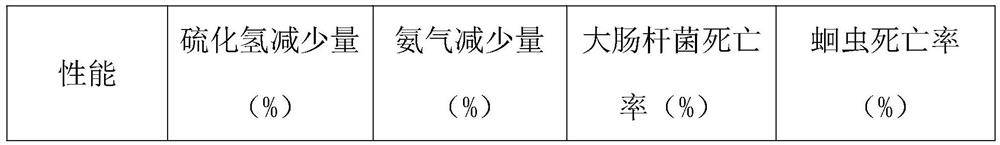

Community life excrement treatment method

PendingCN112645551AImprove transport safetyReduce the content of odorSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesFlocculationOrganic fertilizer

The invention relates to a community life excrement treatment method, relates to the field of excrement treatment, aims at solving the problem that excrement pollutes the environment, and comprises the following steps that S1, collecting excrement into a collection container on site; s2, carrying out primary deodorization and flocculation on the excrement in the collection container; s3, conveying the excrement in the collection container to an excrement treatment station, and performing secondary deodorization, primary degradation and heating fermentation on the excrement to complete sterilization; and s4, carrying out dehydration fermentation on the sterilized excrement, wherein biogas obtained by fermentation is used for power generation, the dewatered excrement residues are used for preparing an organic fertilizer, and the dehydrated water is used for preparing a liquid organic fertilizer. Excrement can be treated and recycled, the influence of excrement on the environment is effectively reduced, and energy conservation and environmental protection are achieved.

Owner:河南宏景建筑工程有限公司

Device for preparing a solution, in particular in or on a dialysis machine

ActiveUS9993784B2Low costEliminate disadvantagesDialysis systemsMedical devicesSolventBiomedical engineering

Devices for preparing a liquid solution are disclosed. The device includes a receptacle defining a cavity for receiving at least one active substance to be dissolved, at least one inlet leading into the cavity for feeding at least one solvent into the cavity, and at least one outlet leading out of the cavity for discharging the liquid solution including the at least one active substance and the at least one solvent from the cavity. The cavity or the receptacle may include a flexible outer shell for enclosing the cavity and an inner, preferably columnar, supporting element for stretching the flexible outer shell between at least two points, the supporting element comprising the at least one inlet at its first end and the at least one outlet at its second end and being enclosed by the flexible outer shell to provide an axially rigid cartridge that can be used in currently customary dialysis machines comprising cartridge connection systems, which can be produced at low cost.

Owner:B BRAUN AVITUM

Autonomous scouting rail vehicle

ActiveUS11465659B2Save livesReduce property damageRailway inspection trolleysSignalling indicators on vehicleControl theoryEmergency brake

Owner:FILIPPONE CLAUDIO

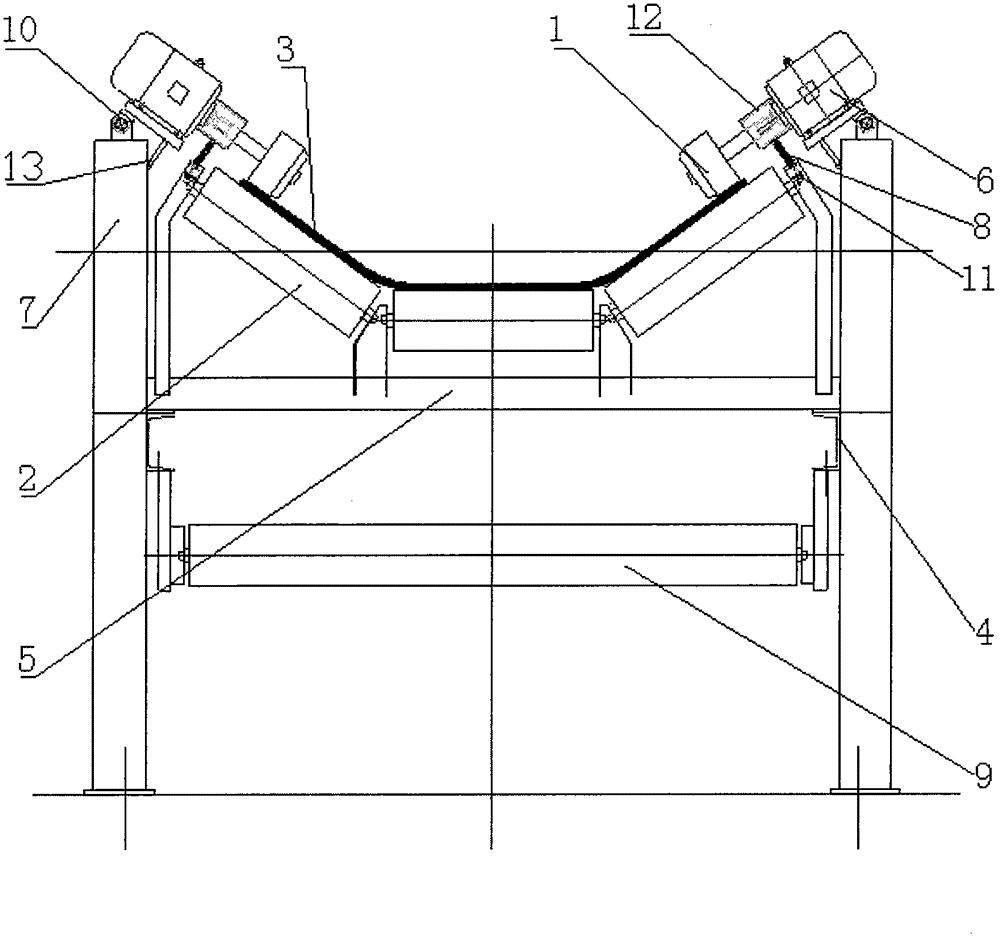

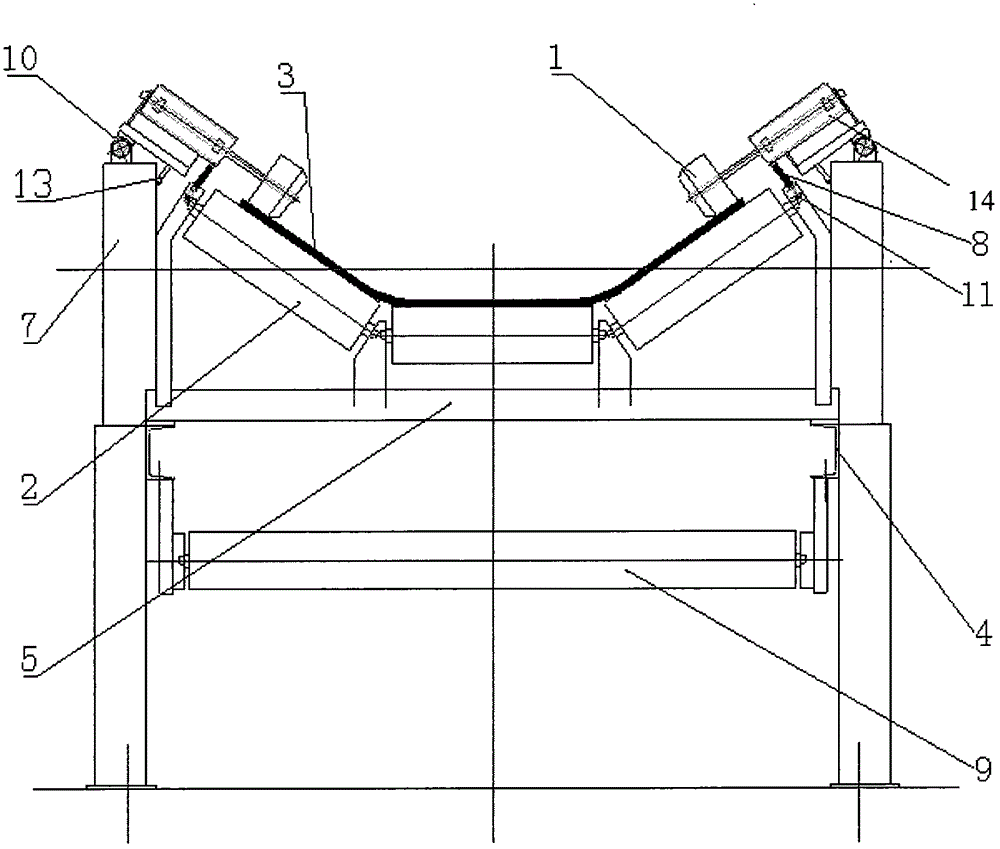

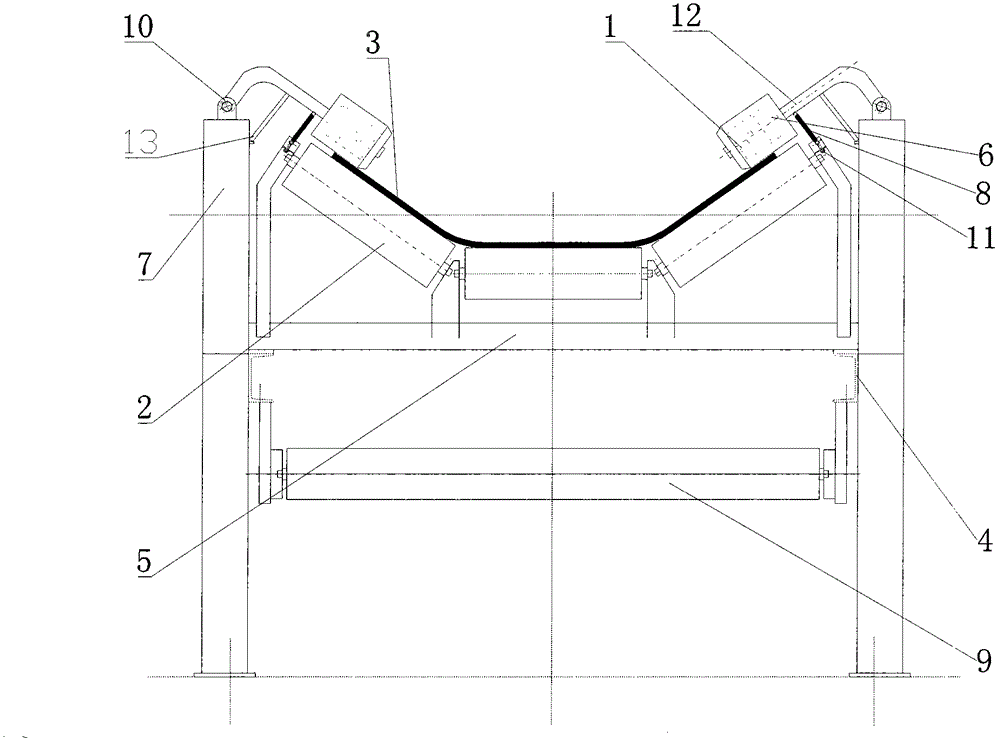

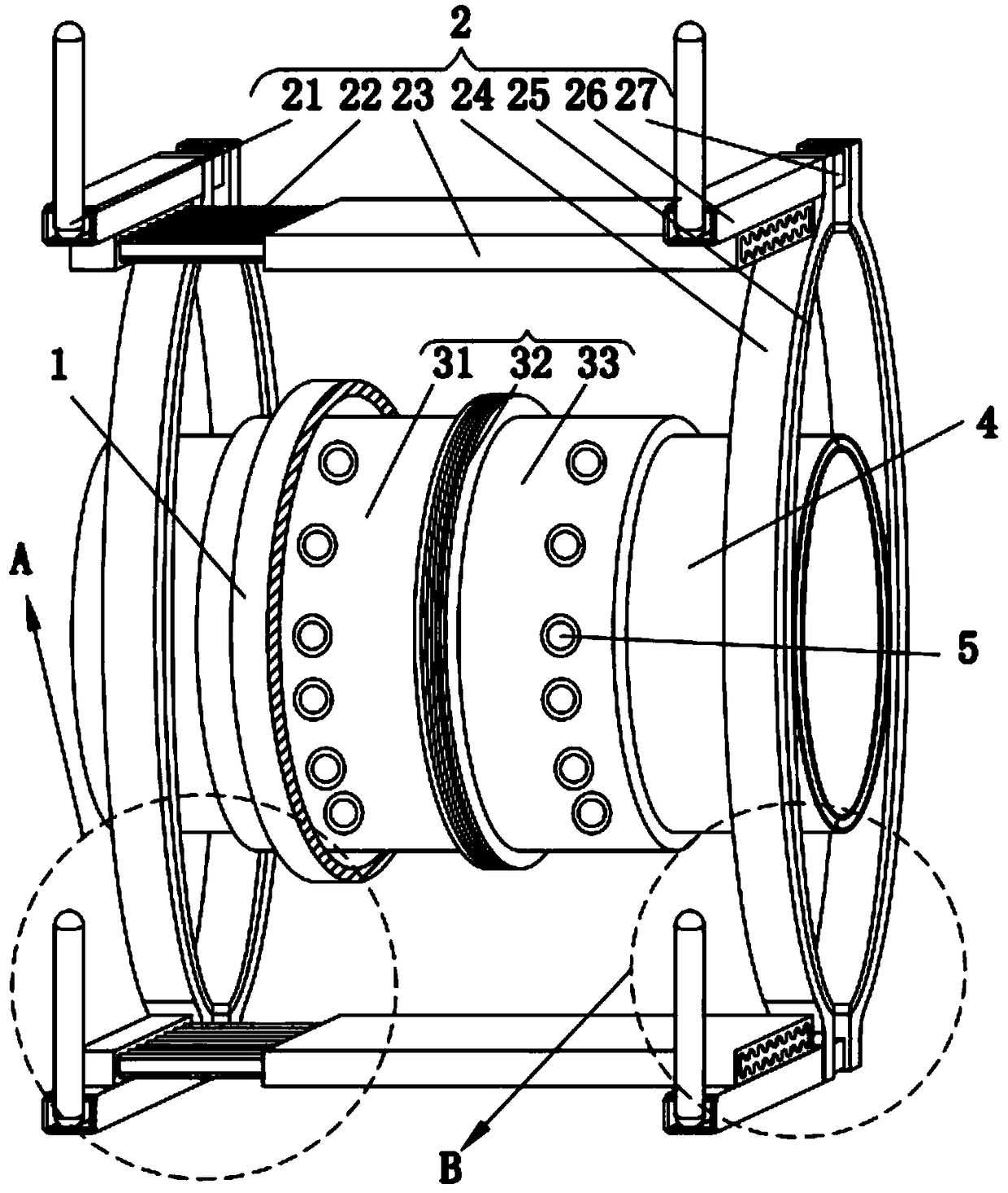

A multi-power entrainment drive belt conveyor

ActiveCN104555330BReduce the number of configurationsIncrease frictionRollersEngineeringBelt conveyor

The invention discloses a multi-power belt clamp drive belt conveyor. The belt conveyor comprises a rubber belt, rubber belt compression rollers, a power roller, a roller bracket, an intermediate rack of the belt conveyor, tension springs, stop rods and a mechanical rubber belt compression roller mechanism; the power roller comprises upper groove-shaped power rollers at the two sides and a lower power roller; the rubber belt is arranged between the rubber belt compression rollers and the upper groove-shaped power rollers at the two sides; the rubber belt compression rollers are arranged above the upper groove-shaped power rollers at the two sides and located at the edges of the rubber belt; the roller bracket supports the power roller; the mechanical rubber belt compression roller mechanism is used for fixing the rubber belt compression rollers; the tension springs are connected between the rubber belt compression rollers and upper groove-shaped power rollers; the stop rods are used for regulating the distance between the rubber belt compression rollers and upper groove-shaped power rollers. The multi-power belt clamp drive belt conveyor is stronger in drive power and capable of effectively meeting the super-long distance and large-capacity requirements.

Owner:BEIJING YU RUNHUA SCI & TECH DEV CO LTD +1

Petroleum pipeline

ActiveCN109340462AImprove transport safetyImprove installation efficiencySleeve/socket jointsPipe supportsDislocationPetroleum engineering

The invention relates to the field of petroleum production and processing equipment, in particular to a petroleum pipeline. The petroleum pipeline comprises dust-proof sleeves, positioning structures,limiting structures, a plurality of pipeline bodies and sealing structures; the sealing structures for sealing are arranged at the adjacent ends of the multiple pipeline bodies for delivering petroleum; the adjacent ends of the multiple pipeline bodies are limited through the positioning structures, the adjacent ends of the multiple pipeline bodies are connected with the limiting structures usedfor secondary sealing; and the dust-proof sleeves are arranged at the junctions of the limiting structures and the pipeline bodies. According to the petroleum pipeline, the two pipeline bodies are limited conveniently through use of the positioning structures, dislocation in the mounting process is avoided, the pipeline bodies are supported conveniently during using, and thus force bearing of theends of the pipeline bodies is more even; meanwhile, the pipeline bodies are limited through cooperation of the limiting structures, and thus the ends of the two pipeline bodies make contact with thesealing structures in an abutting mode; and meanwhile, secondary sealing is achieved through cooperation of the limiting structures, thus the sealing property of the connected pipeline bodies is improved greatly, and the delivering safety of petroleum is improved.

Owner:众一伍德工程有限公司

Material conveying device for construction space operation

ActiveCN109160437BAvoid manual throwing and deliveryReduce labor burdenPortable liftingHydraulic cylinderDrive wheel

The invention discloses a material conveying device for building space operation. The material conveying device comprises a base and a hoisting disc, supporting legs are arranged at the bottom of thebase, a lifting rod is slidably mounted on the base, and the lifting rod penetrates through the upper side and the lower side of the base; guide sleeves are arranged on the upper side and the lower side of the base, and can guide the lifting rod, the lifting rod is provided with a second driving wheel, the lifting rod can be driven to ascend and descend through the second driving wheel, and the second driving wheel is located inside the base and is rotationally connected with the base; and a first driving wheel is arranged on one side of the second driving wheel and can drive the second driving wheel to rotate, a motor is arranged on one side of the first driving wheel, and a hydraulic cylinder is arranged below the base. The material conveying device for building space operation has the beneficial effects that stable lifting of materials and tools can be realized, so that manual throwing and delivery are avoided, and the labor burden is reduced; and an upward lifting force can be applied to the hoisting disc through auxiliary lifting devices, so that the output force of the motor is reduced.

Owner:江西云帆环保建材有限公司

A kind of pipe conveying equipment that is not easy to fall

The invention discloses a pipe conveying equipment that is not easy to drop, which can well realize the conveying of pipes, is convenient for detection manipulators to put down the pipes after random inspection, and effectively reduces the impact of pipes on the conveying equipment when the manipulator puts down the pipes. Adverse effects, reduce shock phenomenon, effectively ensure the reliability of pipe transportation, reduce the risk of pipe falling, effectively ensure the stability and reliability of pipe transportation, improve the safety of pipe transportation, and at the same time, it is convenient for random inspection of the pick-and-place manipulator on the pipe. Pick and place, ensure the pipe pick and place space, realize the seamless connection between the random pick and place manipulator and the pipe conveying equipment, and improve the safety of pipe conveying.

Owner:DALIAN JIAOTONG UNIVERSITY

Automatic Lubricating Device for Vertical Screw Conveyor

InactiveCN106335766BReasonable lubricationHigh degree of automationCleaningLiquid transferring devicesControl lineInlet valve

The invention provides an automatic lubricating device for vertical screw conveyor. An oil outlet piston is arranged on the bottom plate. There is an oil outlet piston rod in the oil outlet piston, which can be usesd to connect to the rotary mechanism. The rotary mechanism is connected with an output shaft of the oil motor. An oil inlet port and an oil outlet are connected to the oil outlet cylinder, and a buffer layer is arranged between the oil cylinder body and the oil outlet port. The oil inlet valve communicates the oil inlet port of the oil cylinder and the oil outlet of the oil drum, and the oil outlet port of the oil cylinder body is connected with the oil inlet port of the plunger pump. The plunger motor is connected with the oil inlet port of the plunger pump through the control line. The oil outlet port of the plunger pump is connected with the oil inlet port of the oil separation device through the hose. The invention delivers the lubricating oil in oil drum, to oil distribution device by plunger displacement pump, and oil distribution device is vertically moved, and the lubricating oil is delivered to vertical screw type conveyer in real time, which is high in automation, and can carry out the reasonable lubrication to vertical screw type conveyer.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Anti-slip safety tensioning device for automobile

ActiveUS10207627B2Simple structureEasy to operateFilament handlingLoad securingEngineeringMechanical engineering

Owner:NINGBO XULI METAL PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com