Pallet-like support base for transport and storage containers for liquids

a technology of supporting base and liquid, which is applied in the direction of packaging, applications, other accessories, etc., can solve the problems of explosive mixture of gases and vapors in closed spaces and flammable substances filled into transport and storage containers, and achieve the effect of improving transport safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

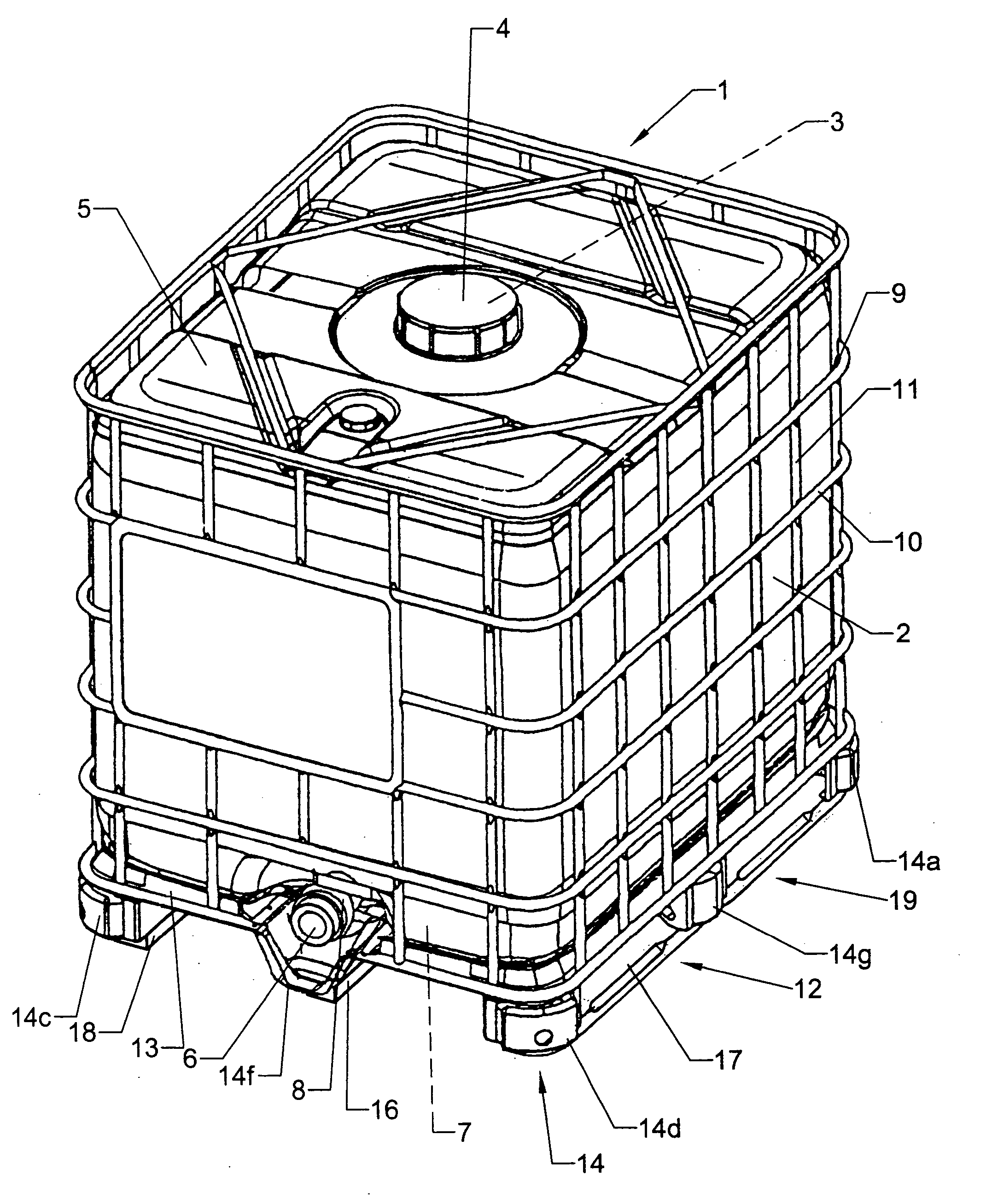

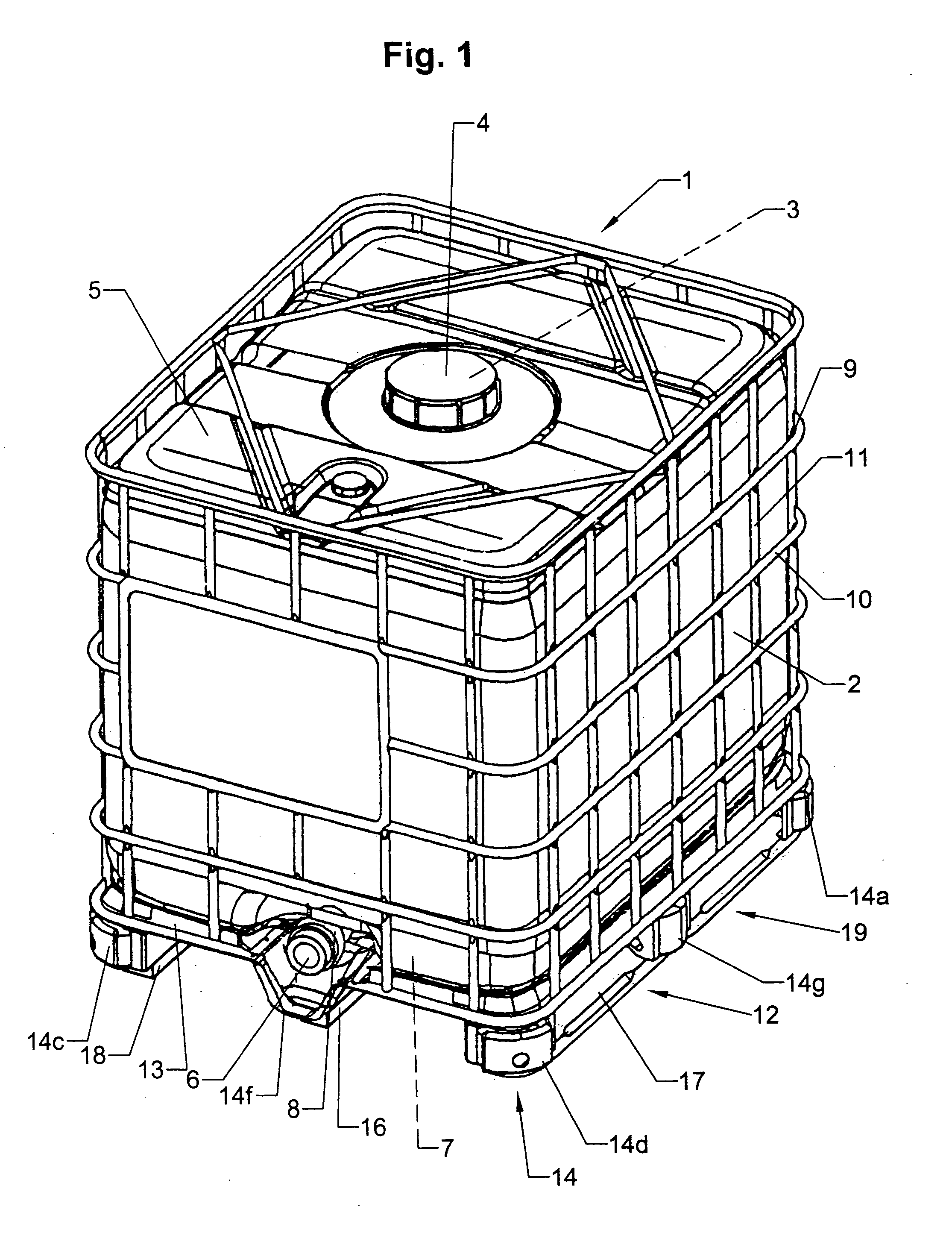

[0014] The transport and storage container 1 for liquids which is used as a single-use or a reusable container has as its primary components a replaceable right parallelepiped-shaped inner container 2 of plastics material which is equipped with a filler connection 3 in the upper top 5 which is closable with a cap 4 and a drain connection 6 in the area of the lower bottom 7 for connecting a drain and flushing valve 8, an outer jacket 9 of intersecting horizontal and vertical grating bars 10, 11 of metal, and a pallet-like support base 12 with length and width dimensions which conform to European standards, wherein a bottom 13 of sheet metal constructed as a flat bottom tub supports the inner container 2 of plastics material.

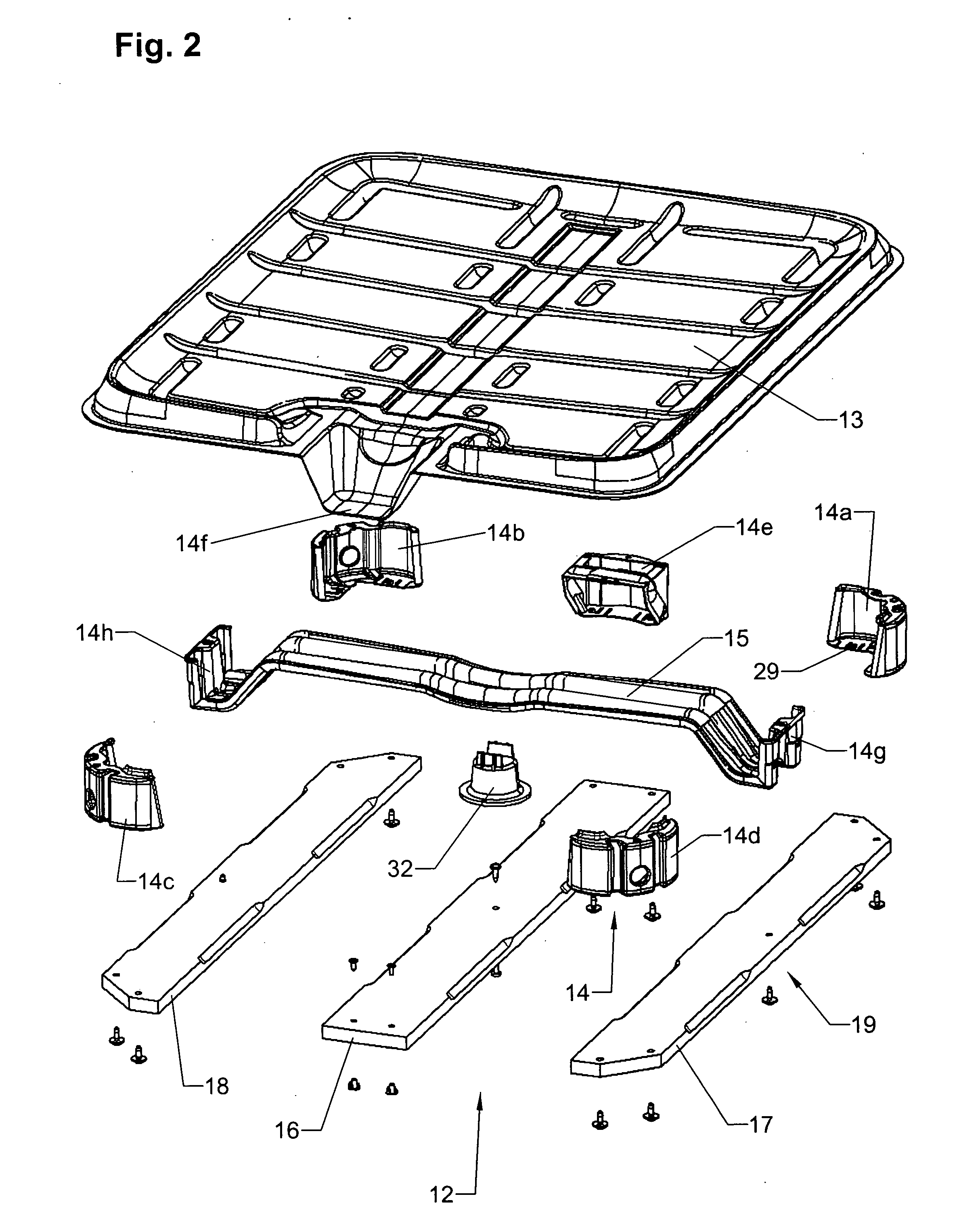

[0015] The tub-like bottom 13 of the support base 12 adapted for manipulation by a forklift, a shelf operating system and the like transport systems, rests on support legs 14 of sheet metal which include the four corner legs 14a to 14d, a rear middle leg 14e, a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com