Exchange vehicle body tank container

A technology of tank container and car body, applied in the directions of packaging, transportation and packaging, containers, etc., can solve the problems of beam bumping, many consumables, weak strength, etc., and achieve ideal impact test results, high overall strength, and excellent force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

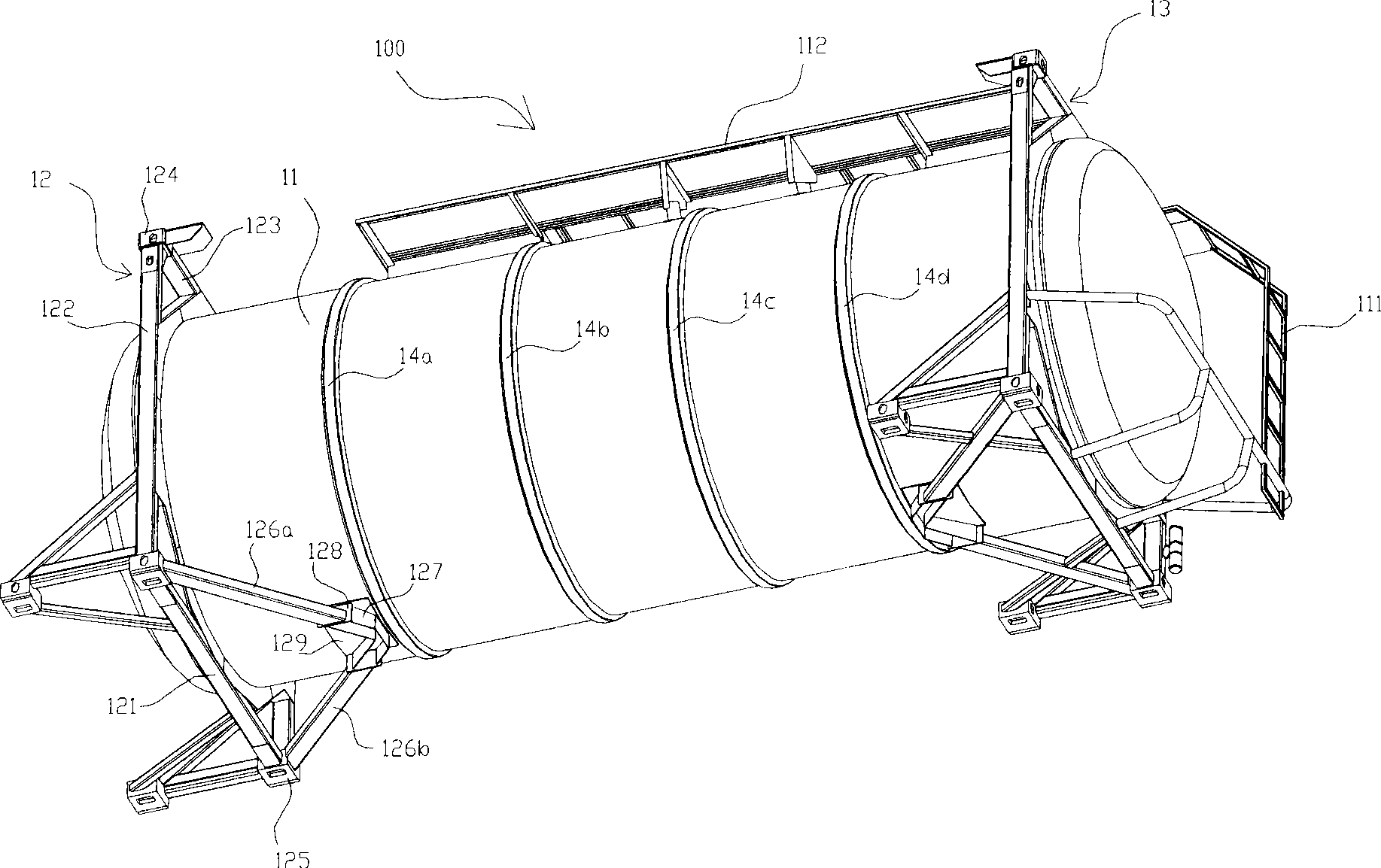

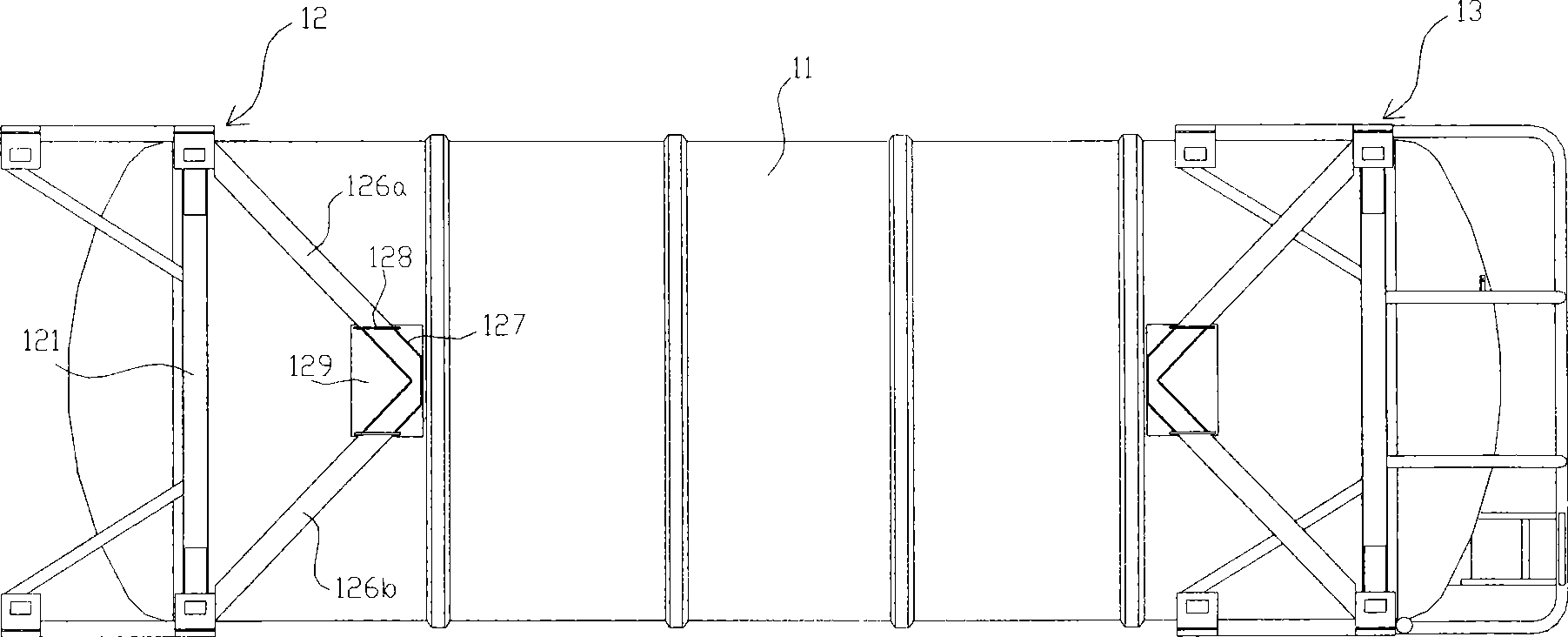

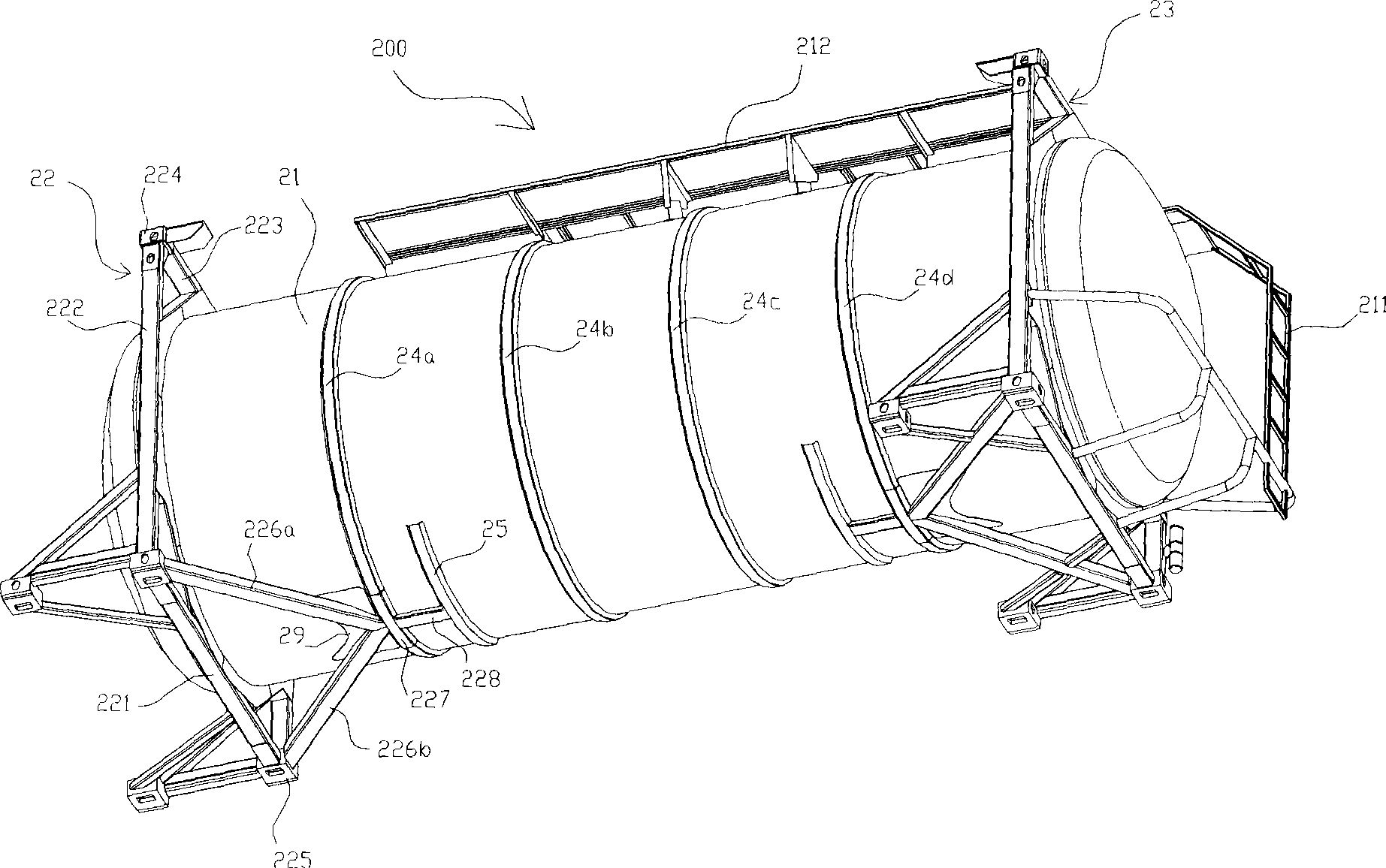

[0025] Such as image 3 , 4 As shown, the exchange body tank container 200 of the present invention includes a tank body 21, a front end frame 22 and a rear end frame 23 arranged at the front and rear ends of the tank body 21, and a plurality of reinforcement rings 24a~ 24d, and escalator 211 and footpath 212 etc. The front end frame 22 and the rear end frame 23 include end lower beams 221 , side beams 222 , and upper end beams 223 , and are provided with top corner pieces 224 and bottom corner pieces 225 . In particular, at least one auxiliary support pipe is provided on the front end frame 22 and the rear end frame 23 of the present invention, for example, two auxiliary support pipes 226a and 226b are provided, which start from the bottom corner piece 225 and extend upwards to the reinforcement ring. 24a, 24d, that is, the first reinforcement ring 24a, 24d closest to the bottom corner piece 225, and welded together with the tank body 21 and the reinforcement rings 24a, 24d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com