High-speed and high-precision tank volume measurement method and device based on three-dimensional laser scanning

A three-dimensional laser and volume measurement technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of limited measurement points and low measurement result accuracy, and achieve short measurement time, high accuracy, and convenient data calculation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

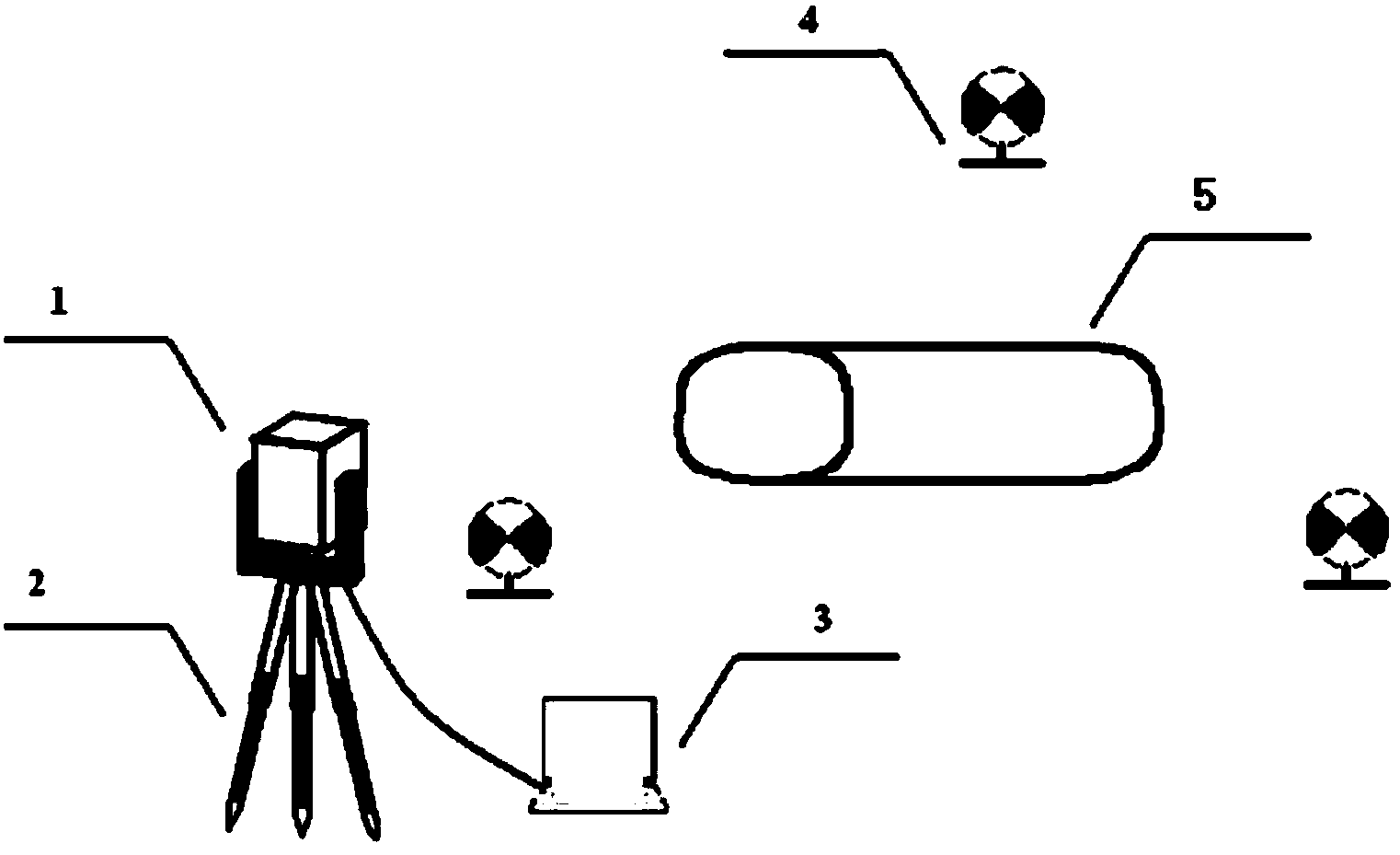

[0037] Example 1: A tank volume measurement device based on three-dimensional laser scanning

[0038] A tank volume measuring device based on three-dimensional laser scanning, characterized in that the measuring device is composed of a three-dimensional laser scanning platform; wherein the three-dimensional laser scanning platform is composed of a three-dimensional laser scanner 1, a tripod 2, a computer 3 and a stitching target 4, The three-dimensional laser scanner 1 is erected on a tripod 2 and connected to a computer 3 through wires.

[0039] The tank volume measurement device based on three-dimensional laser scanning is characterized in that the three-dimensional laser scanner 1 is composed of a laser transmitter, a prism, a receiver synchronized with the prism, a host and a base.

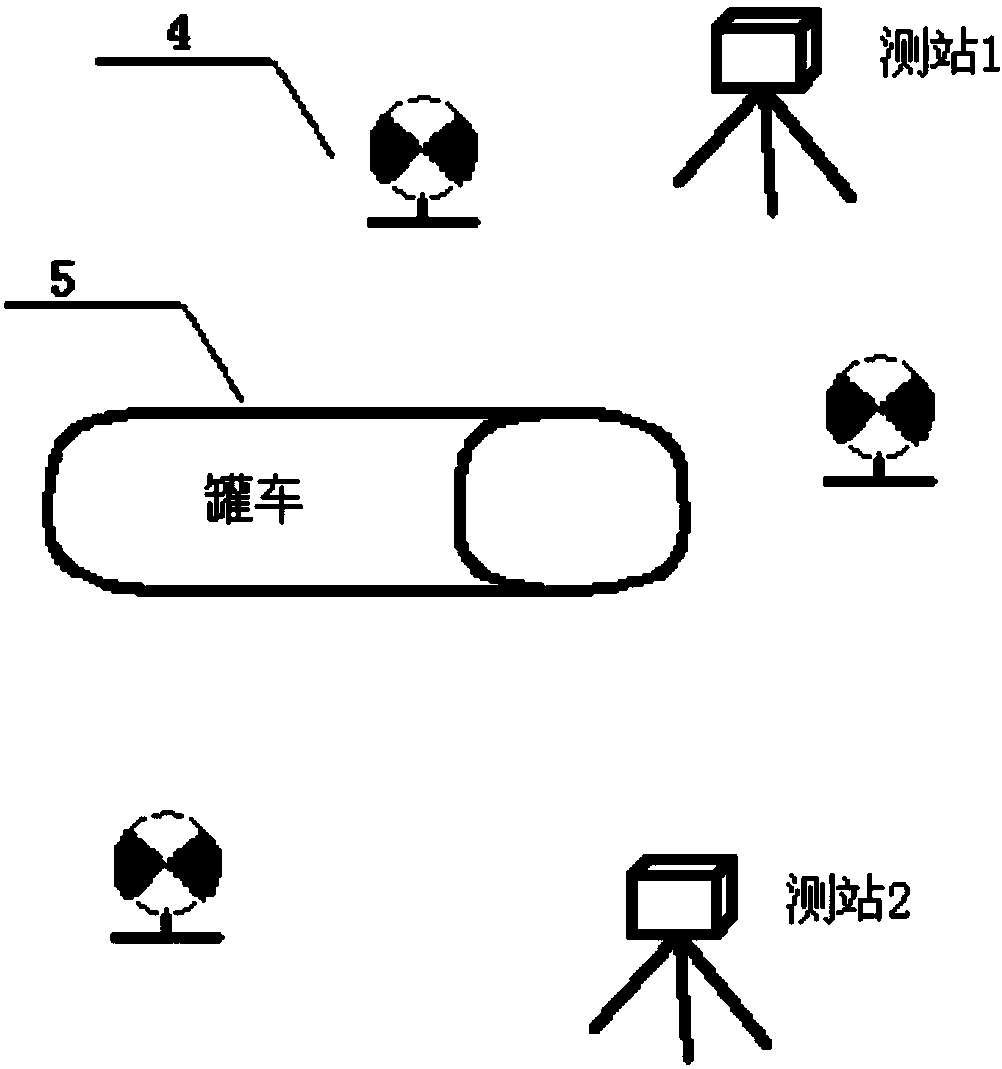

[0040] The tank volume measuring device based on three-dimensional laser scanning is characterized in that the splicing targets 4 are arranged around the tank body 5, 3-6 splicing targets 4 fo...

Embodiment 2

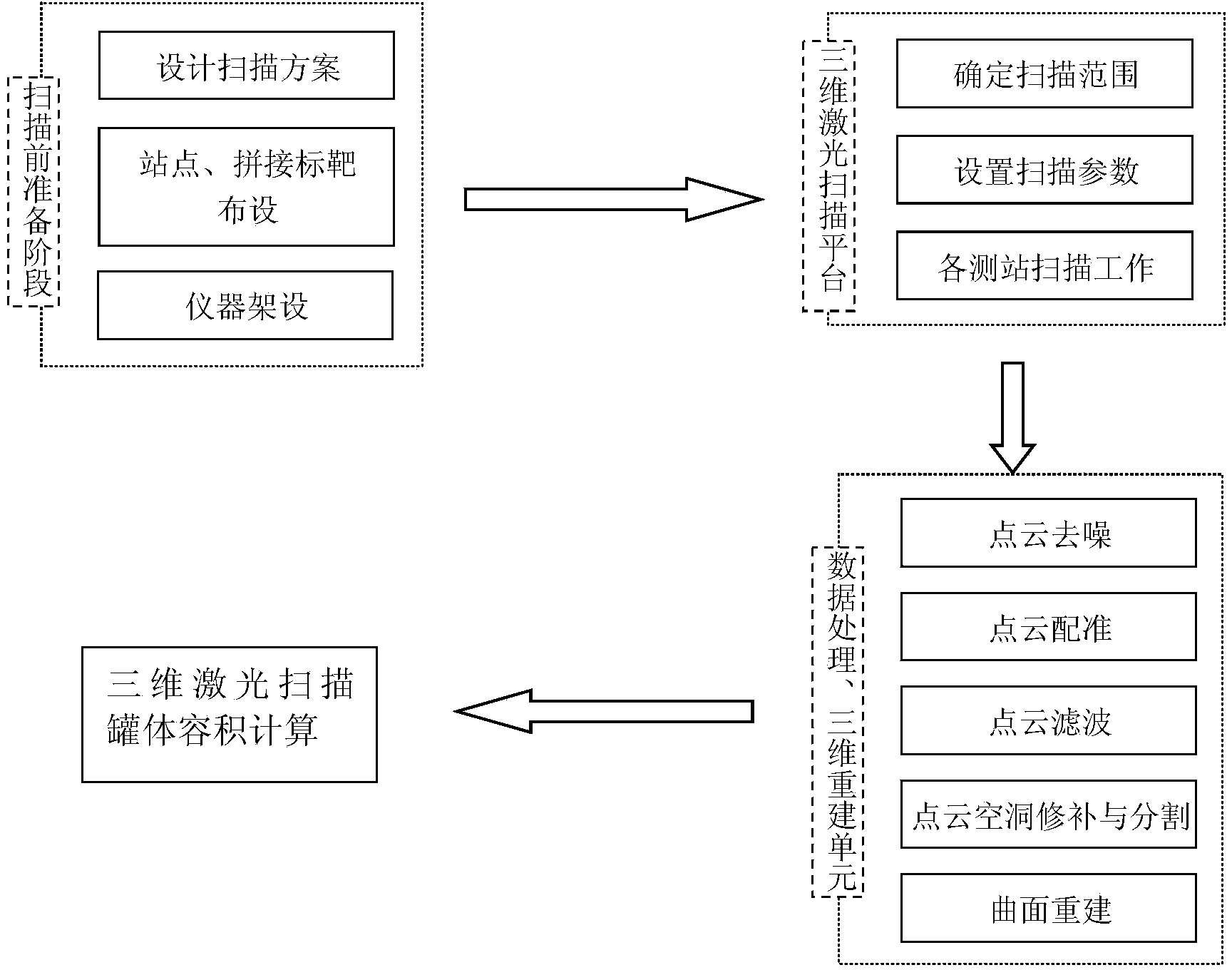

[0044] Embodiment 2: Method for measuring with a fast and high-precision tank volume measuring device based on three-dimensional laser scanning

[0045] The method for measuring with a fast and high-precision tank volume measuring device based on three-dimensional laser scanning is characterized in that the measuring steps are as follows:

[0046] a. According to the shape characteristics of the tank, the spatial position and the accuracy required for scanning, etc., formulate corresponding experimental plans, in which the experimental plan includes determining the model of the scanner, determining the location of the station, scanning distance, scanning angle, scanning distance, and control data Acquisition quality in order to obtain efficient point cloud data in the shortest time, where tanks include tank trucks, storage tanks, and tank containers;

[0047] There are many reasons that affect the accuracy of 3D laser scanning. Among them, the scanning distance is the key fact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com