High-strength and high-plasticity stainless steel composite plate and manufacturing method thereof

A manufacturing method, stainless steel technology, applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve the problem of large difference in thermal processing performance between carbon steel and stainless steel, troublesome anti-corrosion treatment of composite plate cross-section, low temperature impact toughness Unable to guarantee and other problems, to achieve the effect of excellent cold working performance, good cold working and welding performance, high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the embodiments and accompanying drawings. The listed examples are descriptions of the best mode of the invention, but the best mode does not limit the scope of the invention in any way.

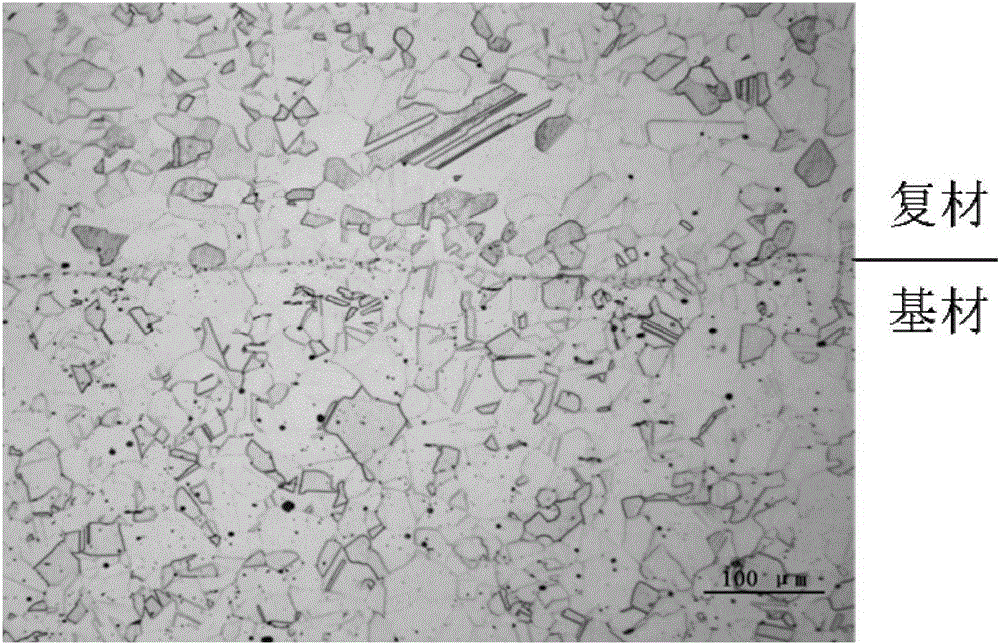

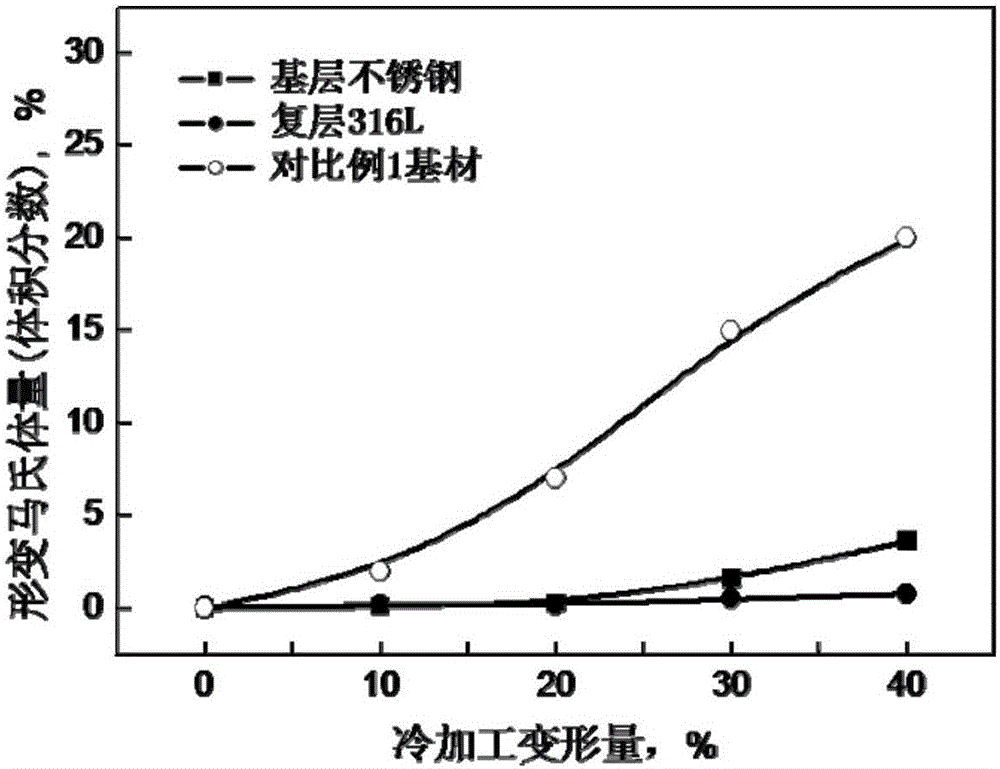

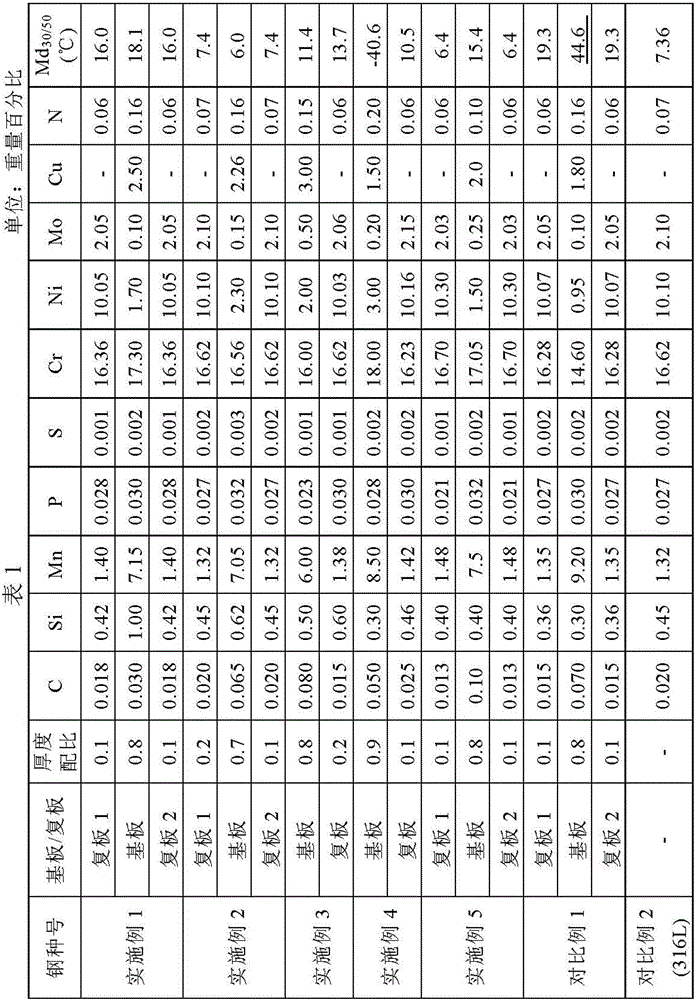

[0041] Table 1 shows the chemical composition and compounding ratio of the base plate and double plate steel of the embodiment of the present invention and the comparative example, and Table 2 shows the key manufacturing process and performance of the composite plate of the embodiment of the present invention and the comparative example.

[0042] According to the chemical composition in Table 1 and the composite ratio of the total thickness of the doubler plate accounting for 10% to 30% of the total thickness of the composite plate, the base plate and the doubler plate are selected and processed, and then the stainless steel composite billet is made by welding. After hot rolling, solid solution, A stainless stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com