Copper-aluminum-manganese alloy and preparation method thereof

A copper-aluminum-manganese and alloy technology, which is applied in the field of non-ferrous metal material preparation, can solve the problems that the strength and plasticity of the alloy cannot be improved at the same time, and achieve the effects of good plasticity, simple production process and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

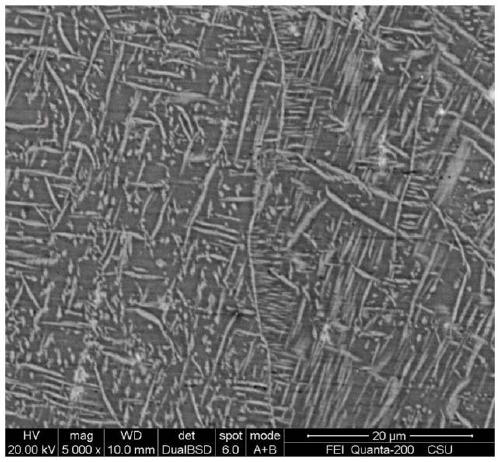

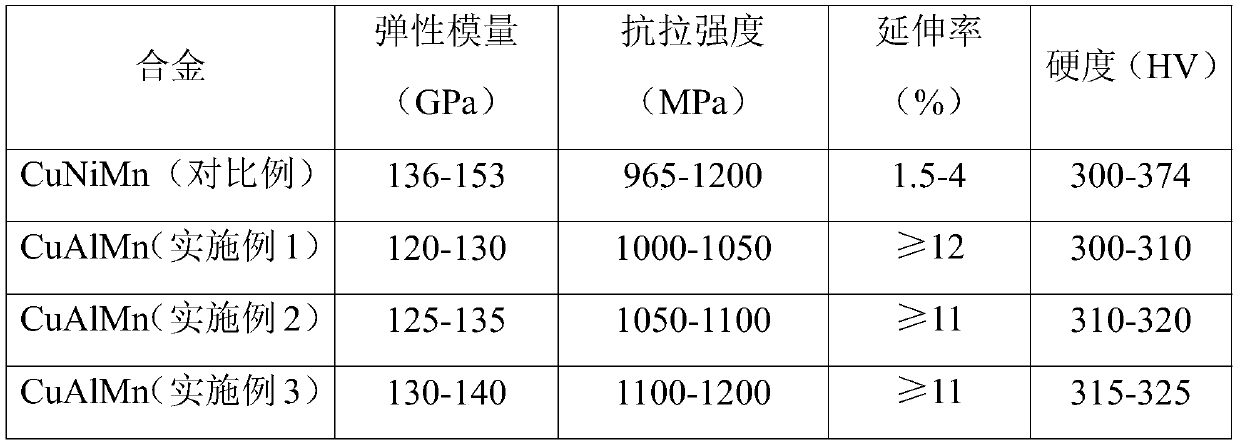

[0041] Therefore, the present invention provides a method for preparing a high-composition copper-aluminum-manganese alloy. In the preparation method, the metastable copper-aluminum-manganese alloy is subjected to a composite deformation heat treatment process of critical temperature processing and aging. Through this process, not only can the α phase be precipitated uniformly and dispersedly in the grain, but also the size of the precipitate is small, so as to significantly improve the plasticity of the alloy without reducing the strength of the alloy.

[0042] The preparation method of described copper-aluminum-manganese alloy comprises the following steps:

[0043] 1) Melting is carried out according to the formula of the alloying element to obtain the alloying element liquid;

[0044] 2) face milling after casting the alloying element solution;

[0045] 3) then rolling;

[0046] 4) Then carry out critical temperature deformation treatment;

[0047] 5) Then carry out agi...

Embodiment 1

[0065] The composition of the alloy ingredients of the present invention is: Al: 9.5%, Mn: 11.5%, and the balance is Cu.

[0066] The specific production process of the alloy is: batching→smelting→hot rolling heating→hot rolling→critical warm rolling→aging.

[0067] Melting: First melt the copper, and after the copper is melted, completely cover the liquid surface of the melt with charcoal. Then add electrolytic manganese, the electrolytic manganese should be wrapped with copper foil, and then added to the melt in batches. After the electrolytic manganese is added, the electrolytic manganese bag should be pressed into the liquid surface, so that the electrolytic manganese is completely melted under the liquid surface, and the oxidation of manganese is prevented. Aluminum is then added and the melt is stirred after adding aluminum to prevent localized overheating.

[0068] Hot rolling: the heating temperature of hot rolling is 800°C, and the heating time of hot rolling is abo...

Embodiment 2

[0073] The ingredients of the alloy in the present invention are as follows: Al: 10.5%, Mn: 11.5%, and the balance is Cu.

[0074] The specific production process of the alloy is: batching→smelting→hot rolling heating→hot rolling→critical warm rolling→aging.

[0075] Melting: First melt the copper, and after the copper is melted, completely cover the liquid surface of the melt with charcoal. Then add electrolytic manganese, the electrolytic manganese should be wrapped with copper foil, and then added to the melt in batches. After the electrolytic manganese is added, the electrolytic manganese bag should be pressed into the liquid surface, so that the electrolytic manganese is completely melted under the liquid surface, and the oxidation of manganese is prevented. Aluminum is then added and the melt is stirred after adding aluminum to prevent localized overheating.

[0076] Hot rolling: the heating temperature of hot rolling is 850°C, and the heating time of hot rolling is ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com