A kind of mg‑al‑zn‑si‑bi alloy and preparation method thereof

An alloy and silicon alloy technology, applied in the field of alloys, can solve the problems of limited refining effect and small improvement in mechanical properties, and achieve the effects of convenient operation, good high temperature stability and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

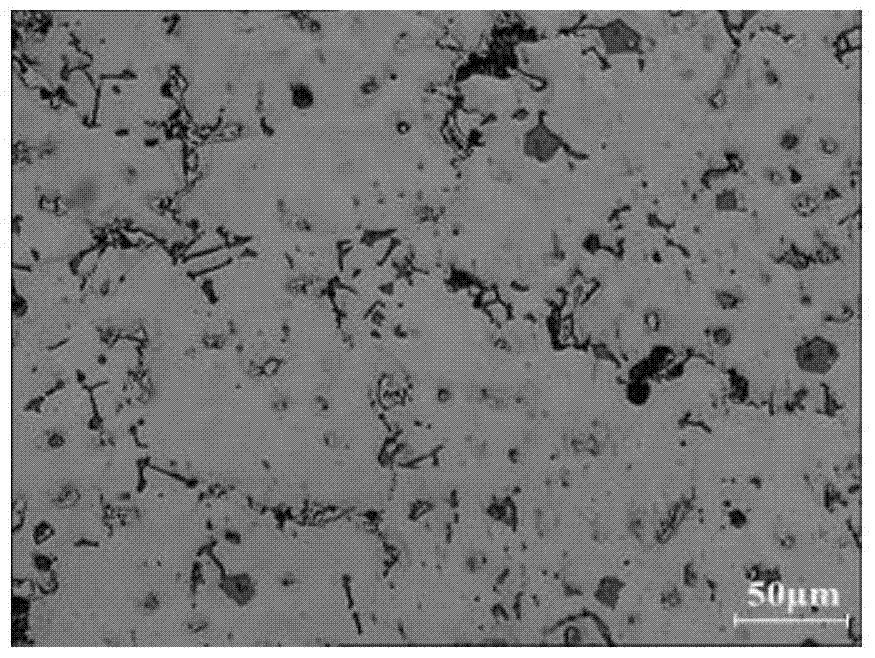

Embodiment 1

[0049] The present invention provides a kind of Mg-Al-Zn-Si-Bi alloy, by weight percentage, comprising:

[0050] 8.5% aluminum, 0.95% zinc, 2.0% silicon, 0.85% bismuth, the balance being Mg and unavoidable impurities.

[0051] The preparation method of a kind of Mg-Al-Zn-Si-Bi alloy described in the present invention is as follows:

[0052] a. According to the above percentages, weigh 2.39g of aluminum block, 8.0g of aluminum-silicon alloy (wherein the mass fraction of silicon element is 25%, and the mass fraction of aluminum element is 75%), 0.95g of zinc particles, 0.11g of aluminum foil, metal Bismuth 0.85g and magnesium block 87.7g;

[0053] b. Place the magnesium block, aluminum block, aluminum-silicon alloy, zinc particles (wrapped with aluminum foil) and metal bismuth in a box-type furnace, preheating at 180°C for 8 minutes;

[0054] c, put the preheated magnesium block into a stainless steel crucible with a temperature of 300°C, and then fill the crucible with protec...

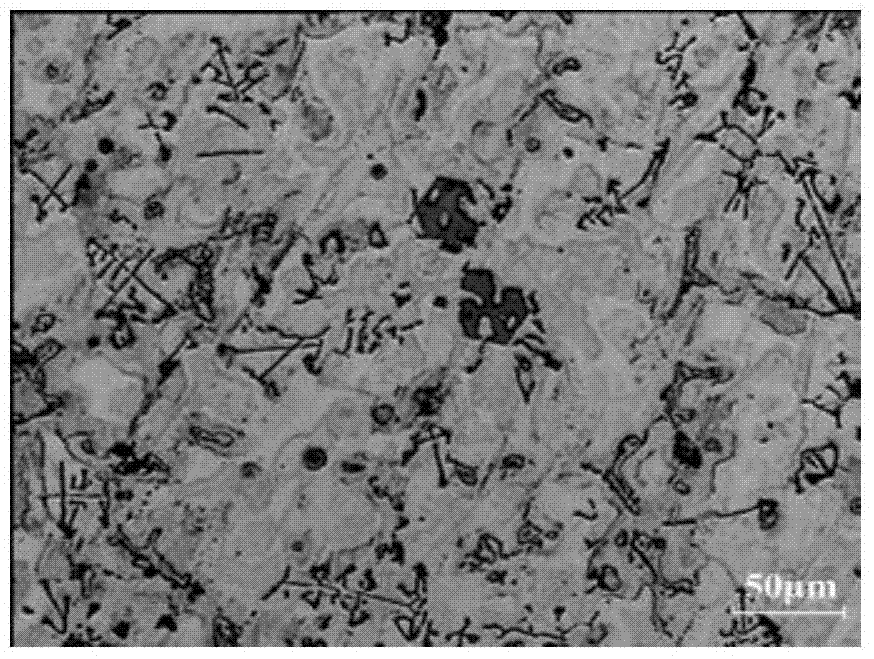

Embodiment 2

[0059] The present invention provides a kind of Mg-Al-Zn-Si-Bi alloy, by weight percentage, comprising:

[0060] 7% aluminum, 1.1% zinc, 1.8% silicon, 1.4% bismuth, the balance being Mg and unavoidable impurities.

[0061] The preparation method of a kind of Mg-Al-Zn-Si-Bi alloy described in the present invention is as follows:

[0062] a. According to the above percentages, weigh 1.48g of aluminum block, 7.2g of aluminum-silicon alloy (wherein the mass fraction of silicon element is 25%, and the mass fraction of aluminum element is 75%), 1.1g of zinc particles, 0.12g of aluminum foil, metal Bismuth 1.4g and magnesium block 88.7g;

[0063] b. Place the magnesium block, aluminum block, aluminum-silicon alloy, zinc particles (wrapped with aluminum foil) and metal bismuth in a box furnace, and preheat at 150°C for 10 minutes;

[0064] c, put the preheated magnesium block into a stainless steel crucible with a temperature of 280°C, and then fill the crucible with protective gas ...

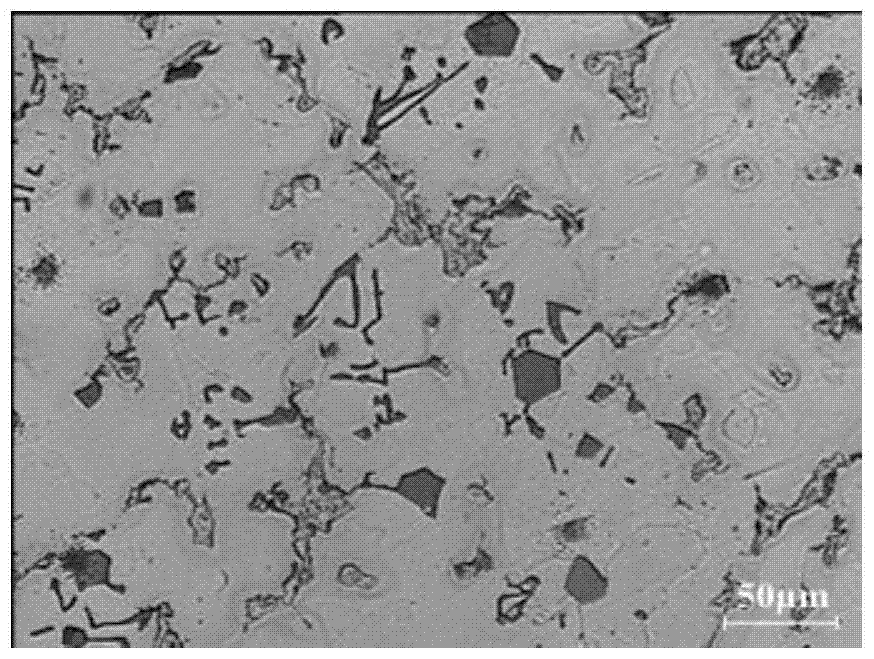

Embodiment 3

[0069] The present invention provides a kind of Mg-Al-Zn-Si-Bi alloy, by weight percentage, comprising:

[0070] 10% aluminum, 0.8% zinc, 2.2% silicon, 0.2% bismuth, the balance is Mg and unavoidable impurities.

[0071] The preparation method of a kind of Mg-Al-Zn-Si-Bi alloy described in the present invention is as follows:

[0072] a. According to the above percentages, weigh 3.29g of aluminum block, aluminum-silicon alloy (wherein the mass fraction of silicon element is 25%, and the mass fraction of aluminum element is 75%) 8.8g, zinc particles 0.8g, aluminum foil 0.11g, metal Bismuth 0.2g and magnesium block 86.8g;

[0073] b. Place the magnesium block, aluminum block, aluminum-silicon alloy, zinc particles (wrapped with aluminum foil) and metallic bismuth in a box-type furnace, preheating at 200°C for 5 minutes;

[0074] c, put the preheated magnesium block into a stainless steel crucible with a temperature of 320°C, and then fill the crucible with protective gas (the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com