1180mpa grade high-strength hot-dip galvanized steel sheet with low hydrogen embrittlement crack sensitivity and preparation method

A crack-sensitive, hot-dip galvanized steel technology, applied in the field of high-strength hot-rolled steel, can solve problems such as failure to meet user requirements, large strength gap, and high martensite content, so as to reduce hydrogen embrittlement sensitivity and strengthen Low strength and susceptibility to hydrogen embrittlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

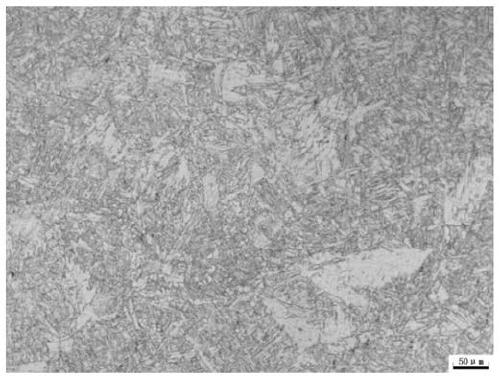

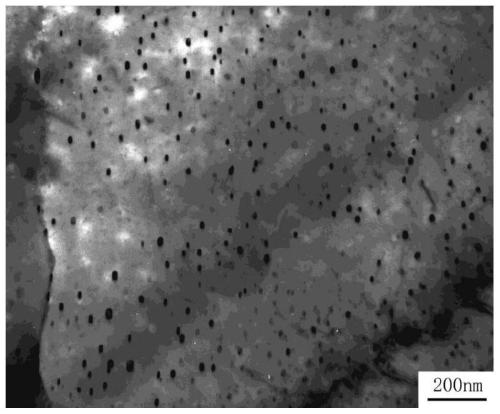

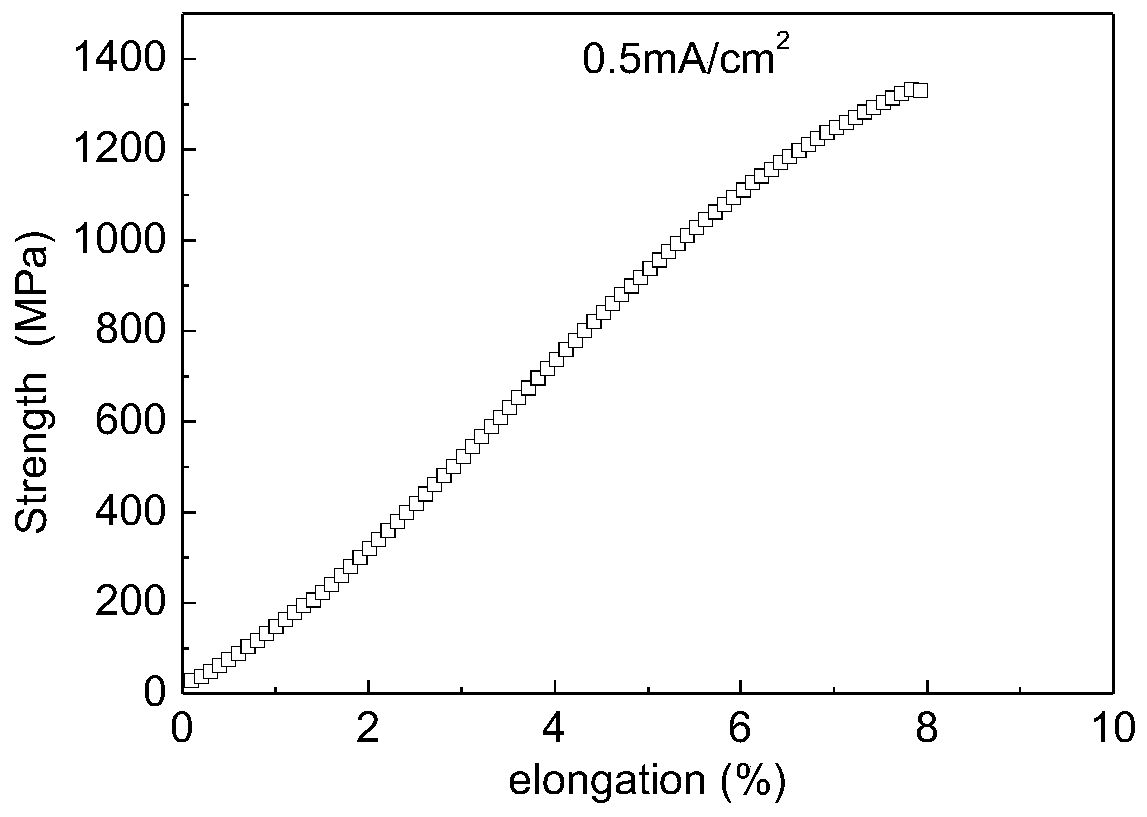

[0042] By controlling the alloy composition of the steel plate, and controlling the hot rolling process parameters such as finishing rolling temperature, reduction ratio, and coiling temperature, nano-scale cluster precipitates can be obtained, and the plasticity and hole expandability of the steel plate can be improved. The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

[0043] Table 1 is the chemical composition list of each embodiment of the present invention and comparative example;

[0044] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

[0045] Table 3 is a list of the performance detection conditions of each embodiment of the present invention and the comparative example.

[0046] Table 1 (wt, %)

[0047] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com