A kind of copper-titanium alloy and preparation method thereof

A copper-titanium alloy and alloy technology, applied in the field of copper-titanium alloy and its preparation, can solve the problems of coarse grains and difficulty in eliminating coarse grains, and achieve the effect of simple process and avoiding a sharp drop in plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

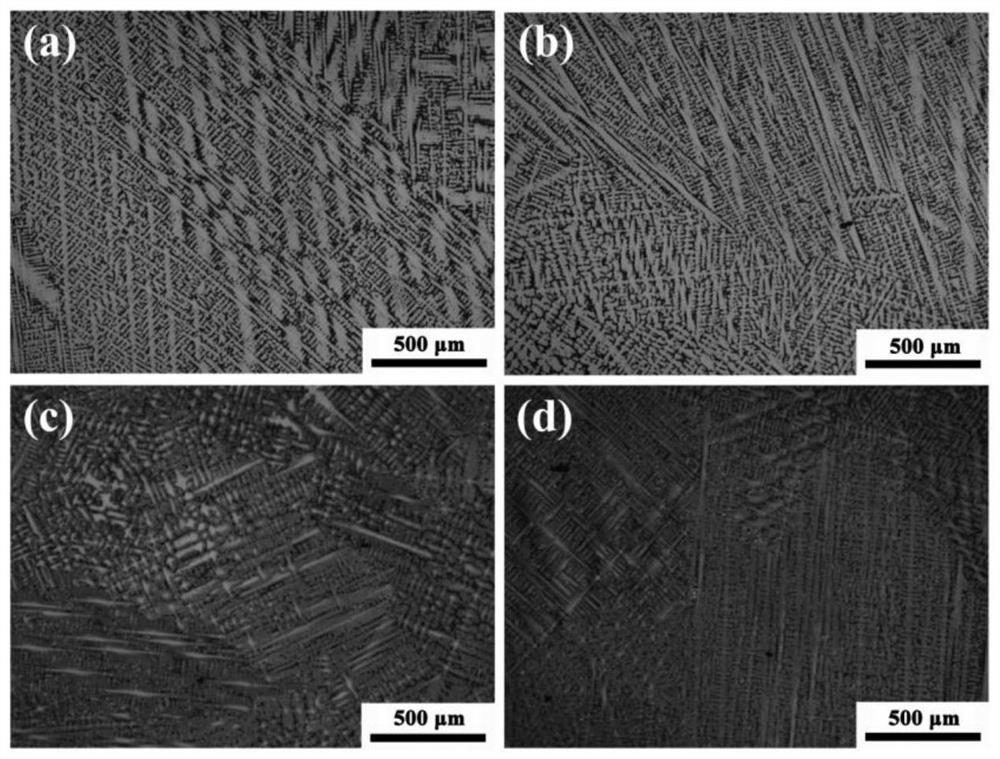

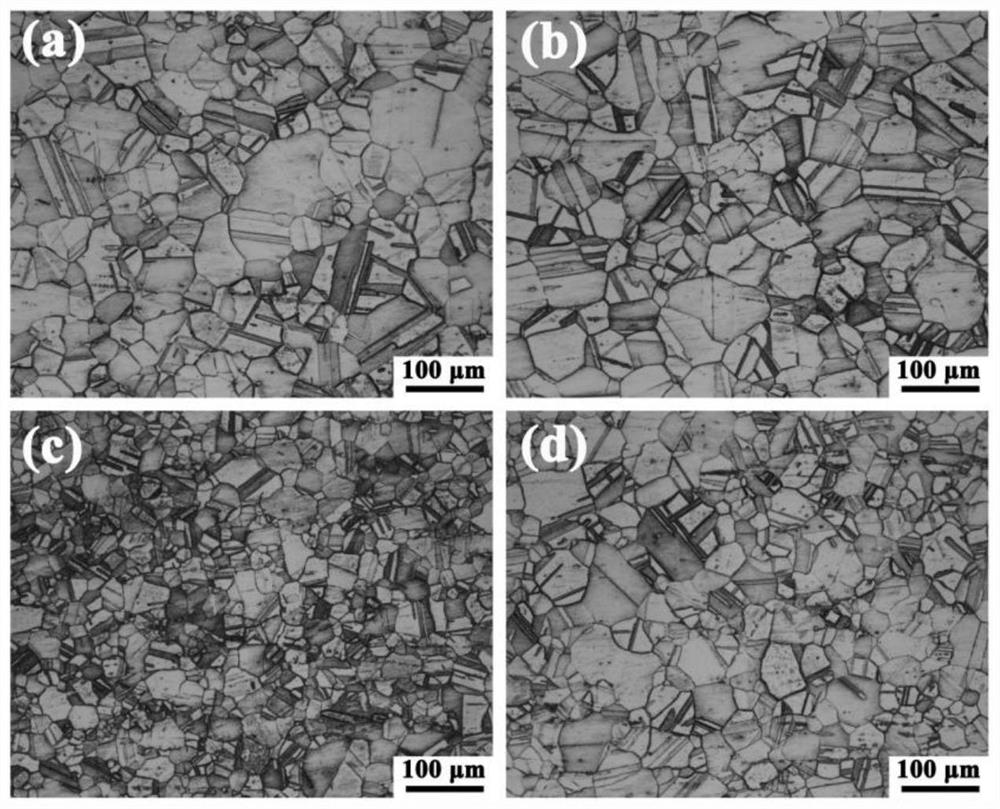

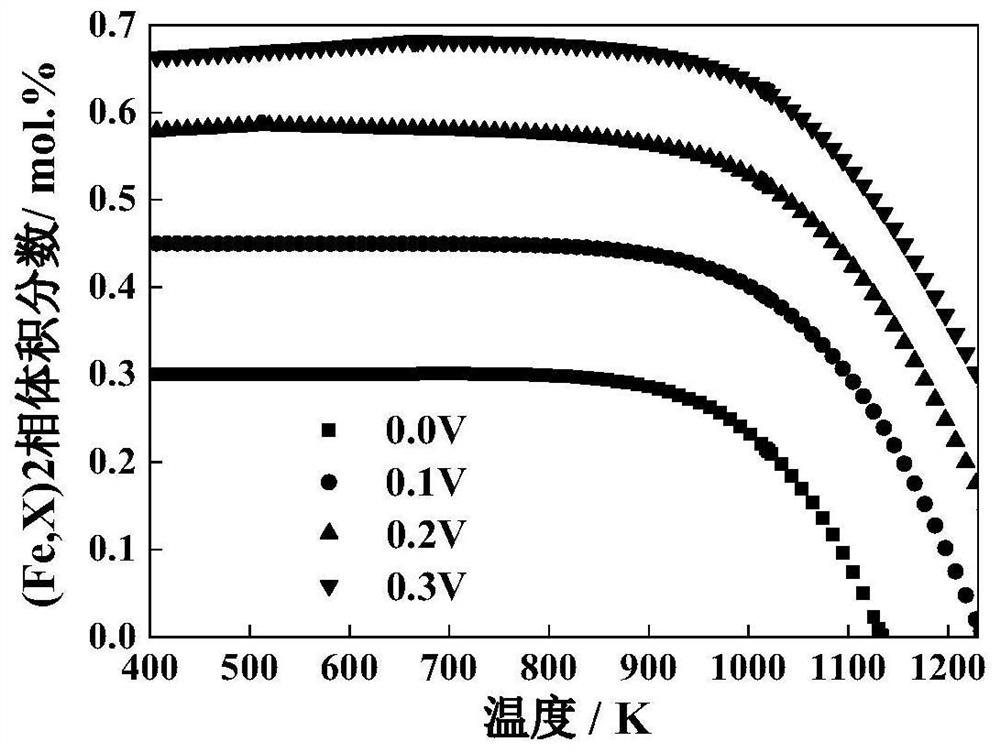

[0070] The preparation method of the invention is simple, and the copper-titanium alloy with a specific structure can be obtained through smelting and casting, thermal processing, primary solid solution, cold processing, secondary solid solution and aging of raw materials. High-temperature short-time annealing treatment makes the prepared structure have ultra-fine grain composition. The alloy grains are mixed crystals composed of 10-30 μm coarse grains and 5 μm ultra-fine grains, and 80% of the grains are less than 5 μm; rapid heating After annealing, 80% of the ultrafine grains in the prepared grain structure are smaller than 2 μm, including sub-grains, nano-twins, and the like.

[0071] The elastic copper-titanium alloy prepared by the method of the invention is a plate, a strip, a bar, a wire or a foil.

Embodiment 1-4

[0076] The copper-titanium alloy preparation method of embodiment 1-4 is:

[0077] Melting and casting: Weigh 10kg of raw materials such as pure titanium or Cu-50Ti intermediate alloy, pure iron, electrolytic copper, and pure vanadium according to the designed composition, put them into a vacuum melting furnace lined with graphite, and evacuate to 10Pa And fill with a certain amount of argon to protect and raise the temperature to 1300 ℃, after the furnace material is completely melted, keep it warm for 20 minutes, and then cast it into an ingot in the furnace.

[0078] Hot processing and primary solid solution: heat the ingot to 900°C in a box furnace, keep it warm for 2 hours, and then carry out hot rolling with a rolling rate of 90%. After hot rolling, a plate is obtained. The final temperature of rolling is 650°C. The plate obtained by hot rolling is placed in a resistance furnace, kept at 900°C for 20 minutes, taken out and immediately water-cooled as a solid solution tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com