Glass fiber sand-fixing net and its weaving method

A glass fiber mesh and glass fiber technology, applied in the field of glass fiber sand-fixing mesh weaving, can solve the problems of inconvenient construction and maintenance, high sand-fixing cost, and difficult operation, and achieve good air permeability, good social economy and ecological environmental protection benefits, The effect of improving the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

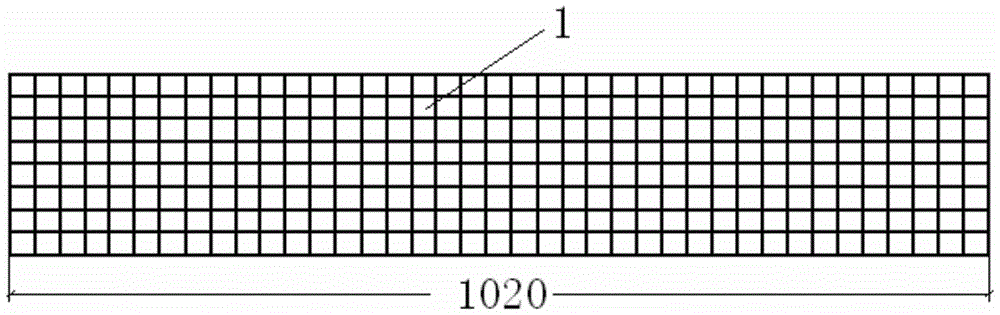

[0075] This embodiment is a glass fiber sand-fixing net.

[0076] The glass fiber sand-fixing net has the same width and the same density, the size of the mesh is 2.5×2.5mm, the fabric weave adopts leno weave, and the mass per unit area is 170g / m 2 , the width is 1000mm. The basic requirements of users are shown in Table 1:

[0077] Table 1 Specifications of glass fiber sand-fixing net proposed by customers

[0078]

[0079] The concrete process of preparing this embodiment is:

[0080] Step 1, determine the technical parameters

[0081] According to the process calculation, design and determine the technical parameters of the glass fiber sand-fixing net as shown in Table 2

[0082] Table 2 Determined technical parameters of glass fiber sand-fixing net

[0083]

[0084]

[0085] Step 2, preparing the base material. The preparation of the substrate includes drawing and spinning.

[0086] Wire drawing: Melt the aluminoborosilicate glass sphere raw material in a c...

Embodiment 2

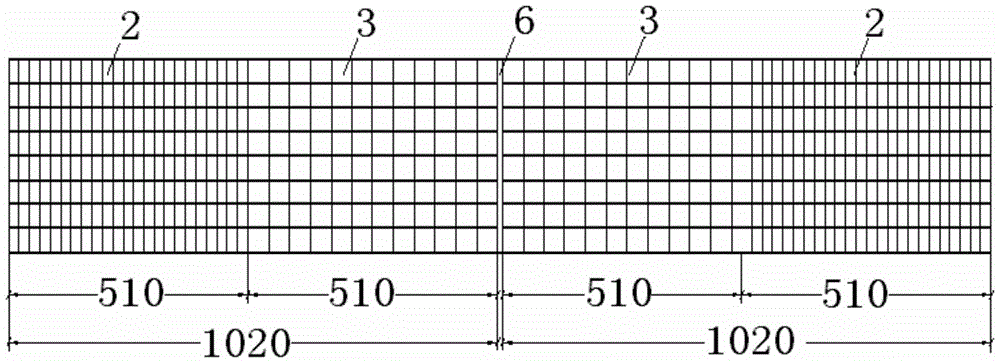

[0104] This embodiment is a glass fiber sand-fixing net.

[0105] The glass fiber sand-fixing net has two different densities of the same width, the mesh sizes are 2.0×2.5mm and 4.0×2.5mm respectively, the fabric weave adopts leno weave, and the mass per unit area is 160g / m 2 and 105g / m 2 , the widths at the two different densities are 500mm respectively. The basic requirements of users are shown in Table 3:

[0106] Table 3 Specifications of glass fiber sand-fixing net

[0107]

[0108] The concrete process of preparing this embodiment is:

[0109] Step 1, determine the technical parameters

[0110] According to the process calculation, design and determine the technical parameters of the glass fiber sand-fixing net as shown in Table 4

[0111] Table 4 Technical parameters of glass fiber sand-fixing net

[0112]

[0113]

[0114] Step 2, preparing the base material. The preparation of the substrate includes drawing and spinning.

[0115] Wire drawing: Melt the ...

Embodiment 3

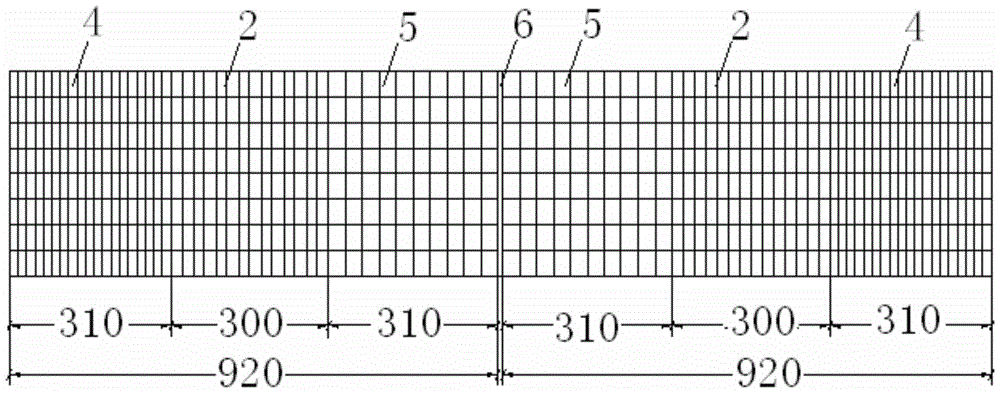

[0132] This embodiment is a glass fiber sand-fixing net.

[0133] The glass fiber sand-fixing net has three different densities of the same width, the mesh sizes are 1.5×2.0mm, 2.0×2.0mm and 3.0×2.0mm respectively, the fabric weave adopts leno weave, and the mass per unit area is 160g / m 2 、140g / m 2 and 115g / m 2 , and the widths at the three different densities are 300mm respectively. The basic requirements of users are shown in Table 5:

[0134] Table 5 Specifications of glass fiber sand-fixing net

[0135]

[0136] The concrete process of preparing this embodiment is:

[0137] Step 1, determine the technical parameters

[0138] According to the process calculation, design and determine the technical parameters of the glass fiber sand-fixing net as shown in Table 6

[0139] Table 6 Technical Specifications of Glass Fiber Sand Fixing Net

[0140]

[0141]

[0142] Step 2, preparing the base material. The preparation of the substrate includes drawing and spinn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com