Multi-objective optimization scheduling method based on iron and steel enterprise energy system

A multi-objective optimization and energy system technology, which is applied in the field of multi-objective optimal scheduling based on the energy system of iron and steel enterprises, can solve problems such as non-convergence in the solution process and failure to output scheduling solutions, so as to solve multi-objective optimal scheduling problems and achieve economic cost and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

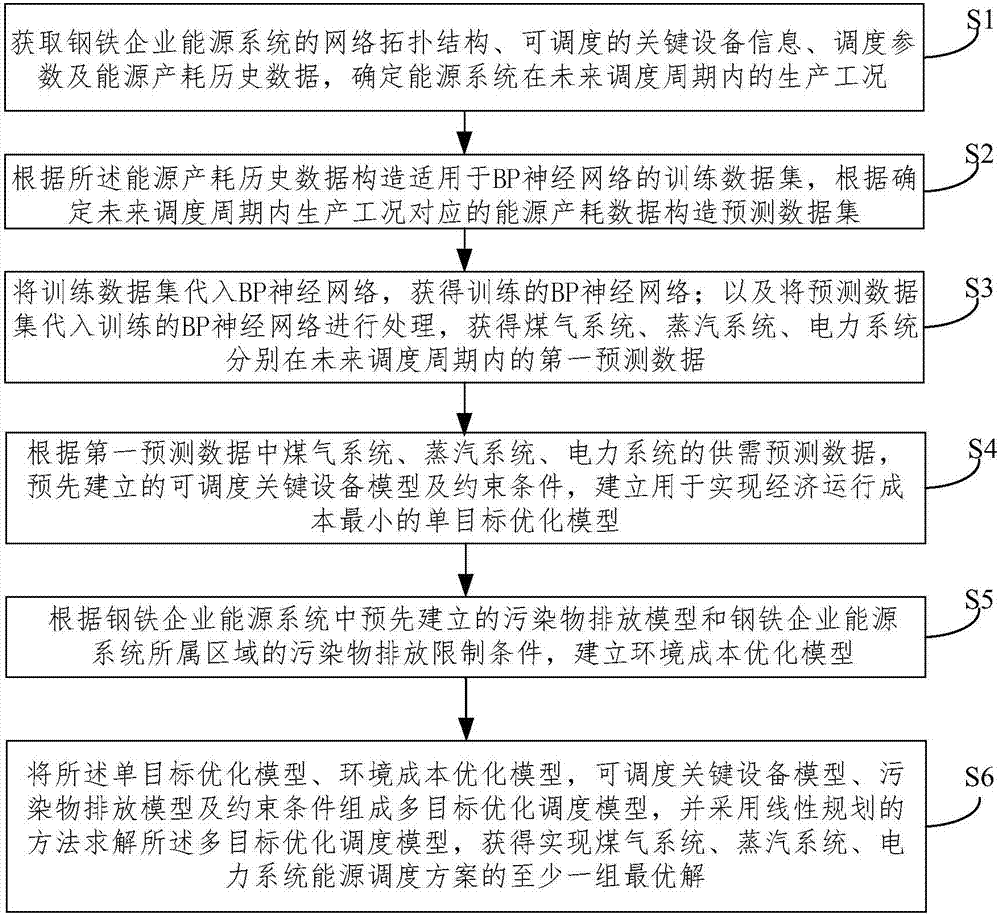

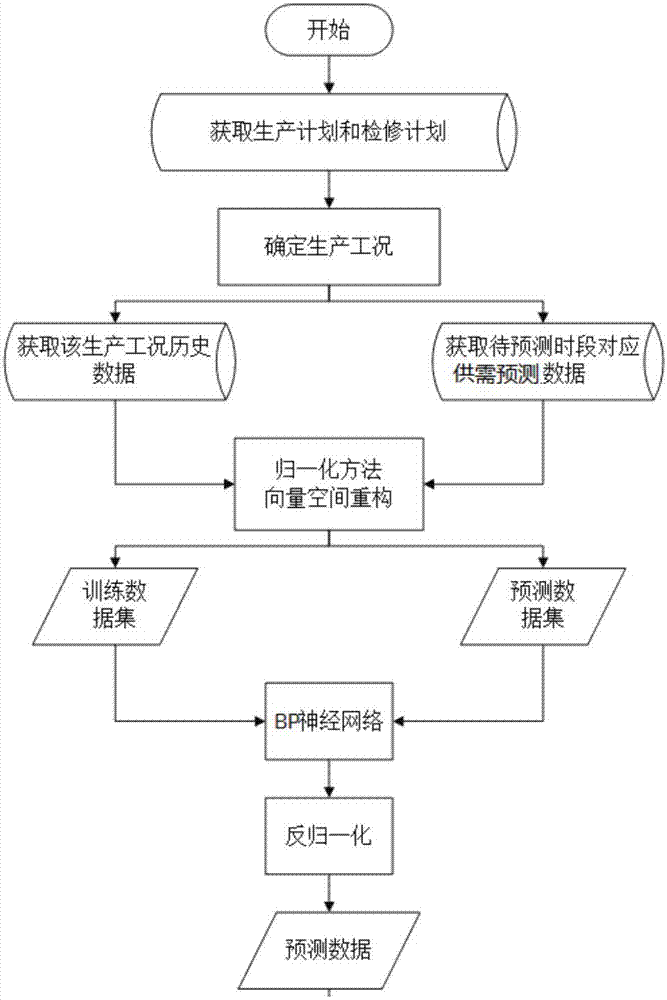

[0056] figure 1 It is a schematic flow chart of the multi-objective optimal scheduling method based on the energy system of iron and steel enterprises provided by an embodiment of the present invention. The execution subject of the method in this embodiment can be an independent processing device, such as a computer and other equipment. The multi-objective optimal scheduling includes the following steps :

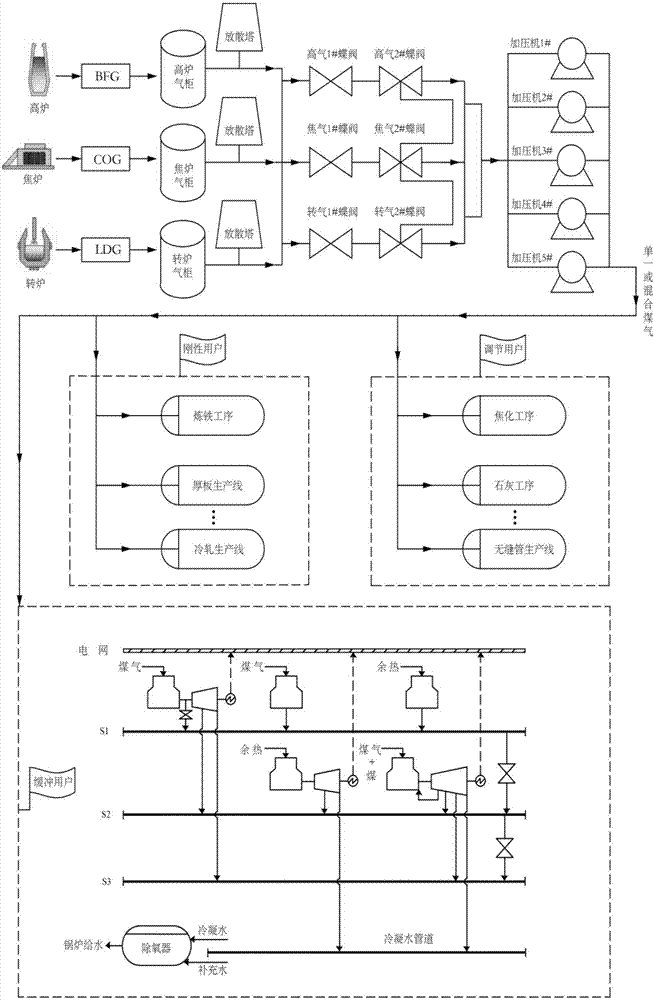

[0057] S1. Obtain the network topology, dispatchable key equipment information, dispatch parameters and historical data of energy production and consumption of the energy system of the iron and steel enterprise, and determine the production conditions of the energy system in the future dispatch cycle; the energy system of the iron and steel enterprise includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com