Test system for evaluating local condensing heat transfer performance of mixed steam

A technology of local condensation and testing system, applied in the direction of thermal conductivity of materials, thermal development of materials, etc., can solve problems such as being limited to vertical pipes, difficult to study internal condensation, etc., and achieve the effect of saving water

Active Publication Date: 2015-03-11

EAST CHINA UNIV OF SCI & TECH

View PDF6 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Due to the asymmetry of condensation in the horizontal tube, it is difficult to study the internal condensation

However, the traditional studies on the condensation of non-condensable gases in pipes are mostly limited to vertical pipes.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

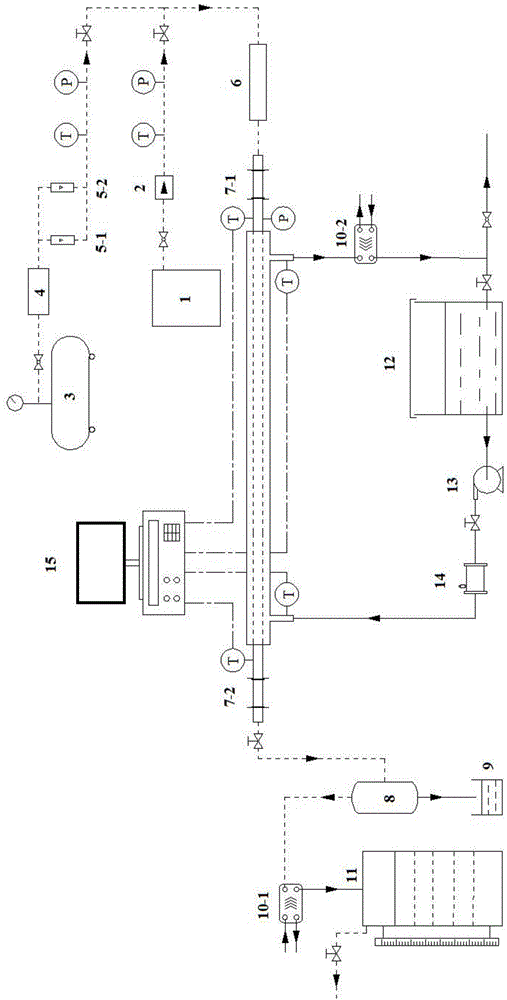

[0035] Please see attached figure 1 , The device for testing the local condensation heat transfer coefficient of mixed steam of the present invention consists of a steam system, a cooling water circuit, a test section, a data acquisition system, and auxiliary pipelines and equipment.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a test system for evaluating the local condensing heat transfer performance of mixed steam. The test system comprises a steam system, a cooling water loop and a data collection system, wherein an air compressor and an air drier of the steam system are connected, air enters a gas mixer together with steam in a boiler after passing through the air drier, and mixed gas enters a test section after being sufficiently mixed in the gas mixer; a water pump of the cooling water loop is used for conveying cooling water to the test section through a flowmeter from a water channel, a cooling water outlet of the test section is connected with an auxiliary cooling device, and the auxiliary cooling device is then connected with the water channel; four valves are arranged at the inlets and outlets of the test section, and are used for controlling the flow rates and pressures of the steam and cooling water respectively. The influence of non-condensable gas on condensation inside a horizontal light pipe can be evaluated by contrasting local condensing heat transfer coefficients.

Description

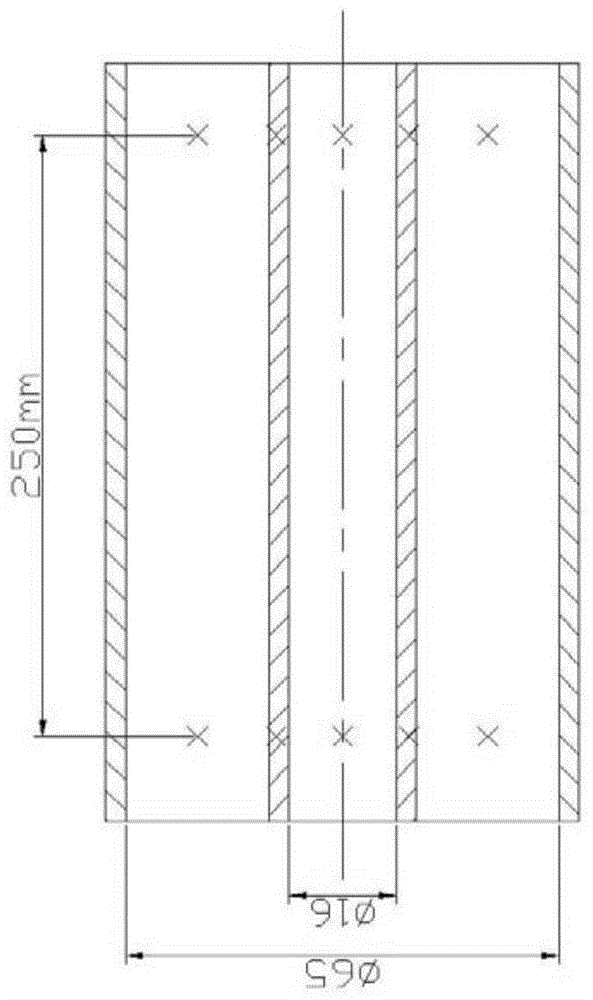

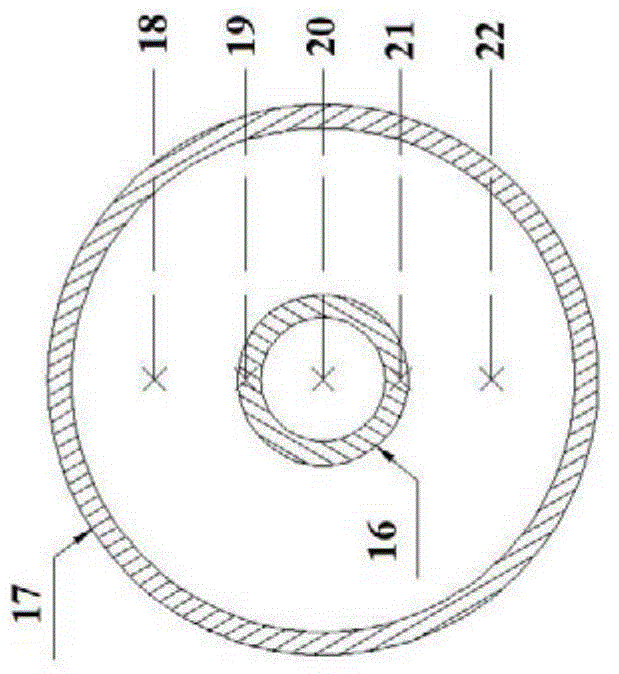

【Technical field】 [0001] The invention relates to the field of heat transfer performance testing, in particular to a device for testing the local condensation heat transfer coefficient of mixed steam. 【Background technique】 [0002] Condensation of steam in the presence of non-condensable gases has many applications, such as air conditioning, power generation, refrigerators, reactor safety, space, seawater desalination, and some heat exchangers. However, we still lack a detailed understanding and prediction of it, especially for the condensation of vapors in the presence of high-quality components. Purified terephthalic acid (PTA) is an important raw material for the production of polyester (PET). With the development of the economy, the demand for PTA has increased dramatically in the past 20 years. In its production process, a series of horizontal condensers are needed to condense the mixed steam from the oxidation reactor. Compared with the vertical condensers, the hori...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N25/18G01N25/20

Inventor 张莉任彬徐宏陶振宇张池鲍斌彬刘波李培俊

Owner EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com