Method for producing electrode material with ferrophosphorus

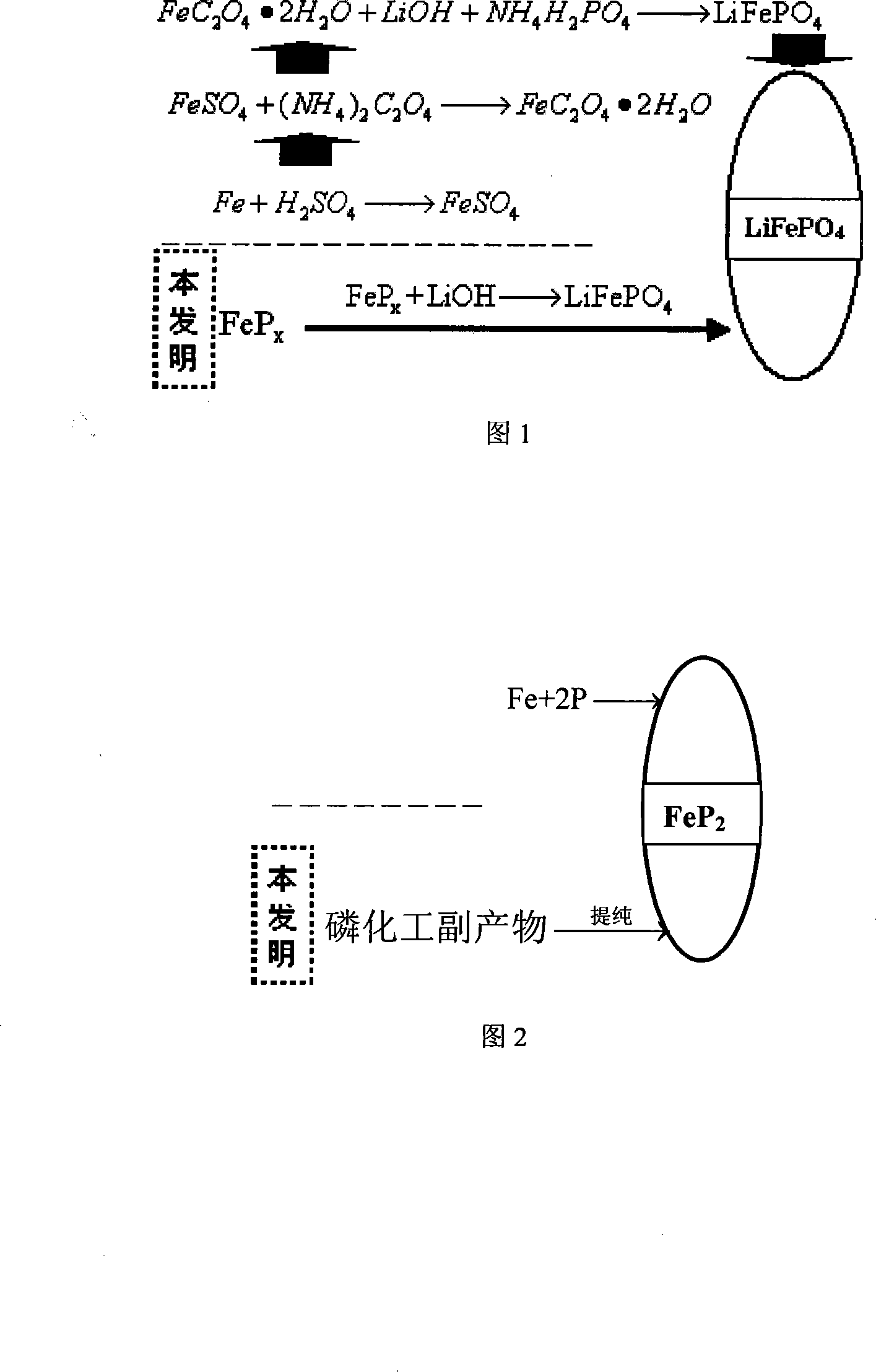

A technology for preparing electrodes and electrode materials, which is applied in the field of materials and electrochemistry, can solve the problems of single raw materials, high preparation costs, shorten the production process of electrode materials, etc., achieve the effects of improving utilization rate, simplifying the preparation process, and having practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of LiFePO from FeP by Reaction Pulverization 4 For the positive electrode material, phosphorus iron is used as phosphorus source and iron source, and LiOH is used as lithium source. Roasting in the furnace for 0.5-10h, controlling a certain air flow, using the oxygen in the air as the oxygen source, and using N 2 or CO burned with C 2 For inert protective gas, get black LiFePO 4 Electrode material, the reaction equation is as follows:

[0026] 4FeP+4LiOH+7O 2 →4LiFePO 4 +2H 2 O

[0027] According to the needs, not only can the material be modified differently by using impurity elements such as Al and V in ferrophosphorus, but also LiFePO can be formed with the raw material. 4 / FeP composite electrode material, using the high conductivity of FeP to improve LiFePO 4 In addition, LiFePO can also be formed by adding different carbon or carbon-containing compounds to the precursors. 4 / C composite electrode material.

Embodiment 2

[0029] Ferrophosphorus FeP, a by-product of a yellow phosphorus production plant, using the rheological phase method 2 Preparation of LiFePO as raw material 4 Cathode material, using phosphorus iron as phosphorus source and iron source, using Li 2 CO 3 For lithium source, add a certain amount of NH 4 H 2 PO 4 Supplement the phosphorus source, the ratio of the three substances is 1:1:1.08, use ethanol as the solvent, and after sufficient ball milling or grinding to form a rheological phase, put it into a controlled atmosphere tube furnace at 200 ~ 700 ° C for roasting for 2 ~ 25h, control a certain air flow, use the oxygen in the air as the oxygen source, and use N 2 or CO burned with C 2 For inert protective gas, get black LiFePO 4 Electrode material, the reaction equation is as follows:

[0030] 4Fe 2 P+4NH 4 H 2 PO 4 +4Li 2 CO 3 +9O 2 →8LiFePO 4 +6H 2 O+4NH 3 +4CO 2

[0031] According to the needs, not only can the impurity elements such as Si, Al, and Ca...

Embodiment 3

[0033] Fe by-product of calcium magnesium phosphate fertilizer production plant by spray drying 1.5 Preparation of LiFePO using P as raw material 4 For cathode material, firstly, ferrophosphorus is pulverized to a certain particle size by jet mill, using ferrophosphorus as phosphorus source and iron source, and using LiH 2 PO 4 LiOH and LiOH are the lithium source, and the ratio of the three substances is 2:1:2.08. After the precursor is spray-dried, it is placed in a controlled atmosphere furnace at 200 to 900 ° C, and N 2 or CO burned with C 2 For inert protective gas, get black LiFePO 4 Electrode material, the reaction equation is as follows:

[0034] 2Fe 1.5 P+LiH 2 PO 4 +2LiOH+4O 2 →3LiFePO 4 +2H 2 O

[0035] According to the needs, not only can the impurity elements such as Ni, V, Ca in the ferrophosphorus be used to modify the material differently, but also LiFePO can be formed with the raw material. 4 / Fe 1.5 P composite electrode material, using Fe 1.5 H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com