Preparation method of aluminum oxide-coated positive electrode material for lithium-ion battery

A lithium-ion battery and cathode material technology, which is applied in the field of preparation of alumina-coated lithium-ion battery cathode materials, can solve problems such as flammability, influence of material structure and electrochemical performance, and volatile organic solvents, so as to avoid potential safety hazards , Improve cycle performance, simple and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of preparation method of aluminum oxide coating lithium ion battery cathode material of the present invention, its specific preparation process is as follows:

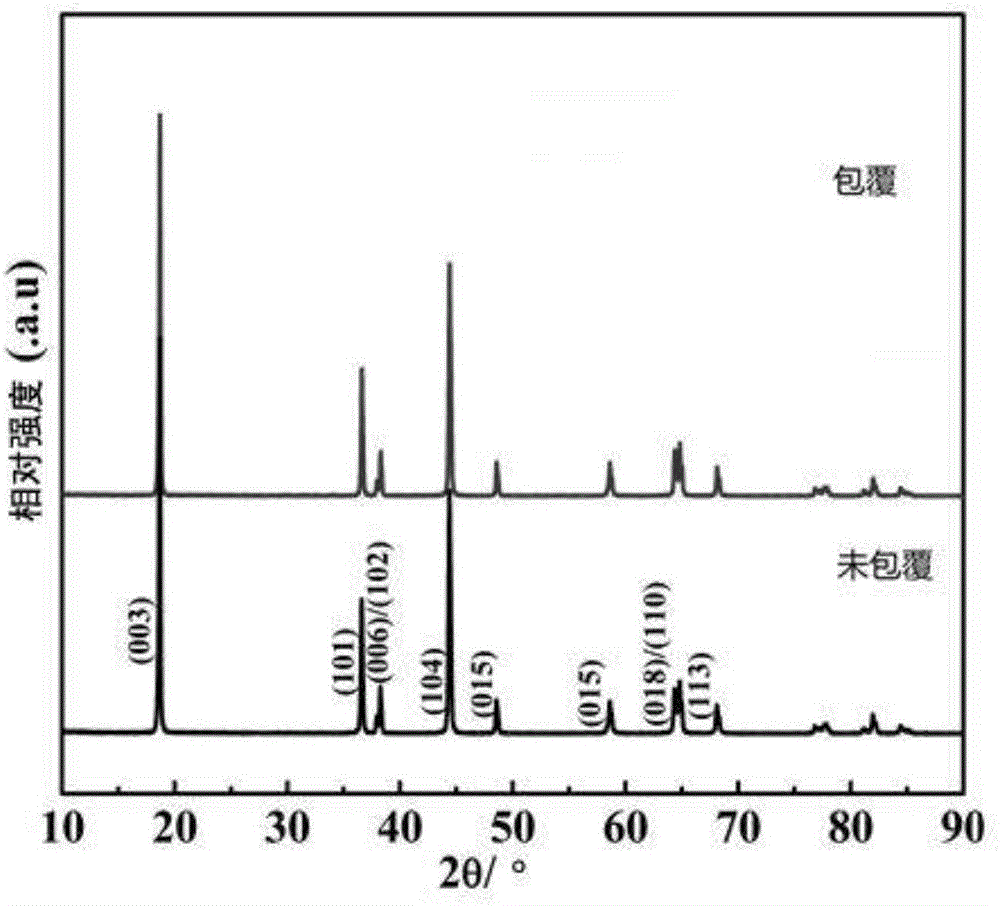

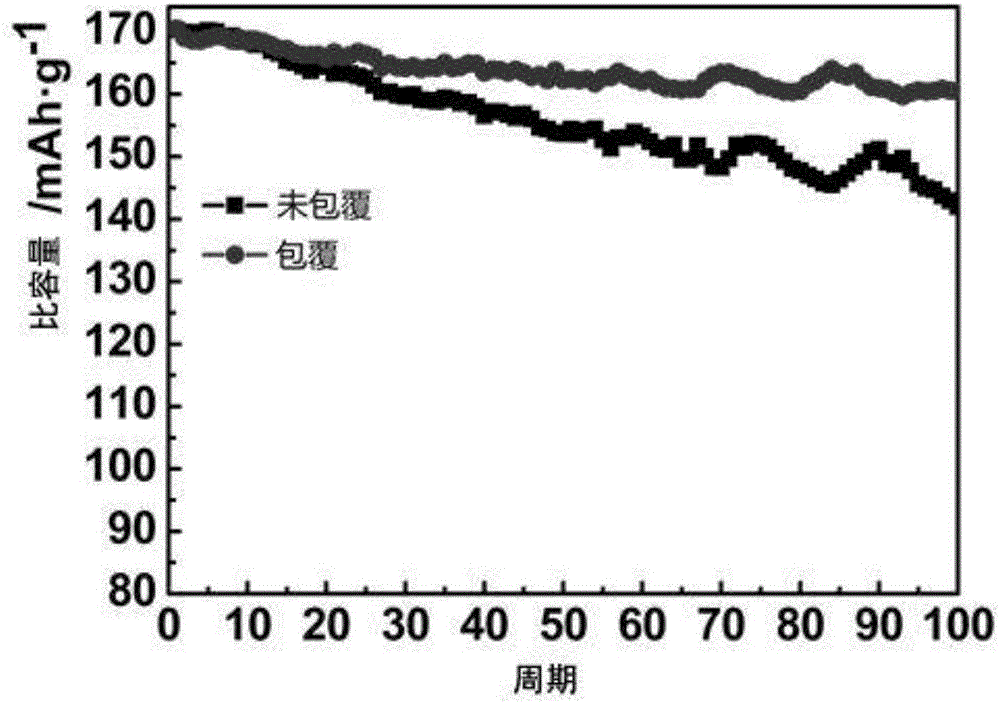

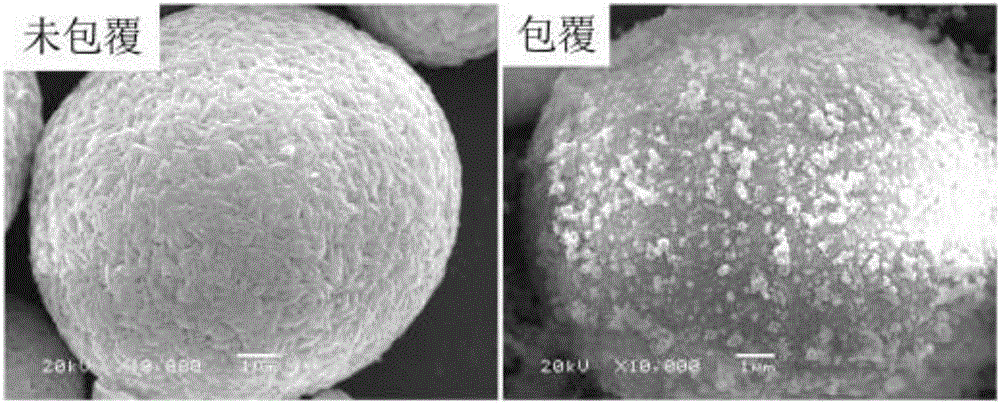

[0036] 10g Ni 0.8 co 0.1 mn 0.1 (OH) 2 The precursor was dispersed with 80ml of deionized water, and the process was supplemented by stirring, and the stirring was stopped after 30 minutes. Dissolve 0.5184g of sodium metaaluminate in 20ml of deionized water according to the coating amount of alumina and 3wt% of the mass coating amount, and mix it with the previously dispersed precursor slurry, and at the same time, introduce CO into the system 2 , stirred at 70±5°C for 120min, washed and filtered, and dried in an 80°C blast drying oven for 12-15h to obtain Al(OH) 3 Coated lithium ion battery cathode material precursor. By performing SEM detection on the coated precursor material, the SEM spectra of the hydroxide precursor before and after coating are as follows image 3 shown. Depend on image 3 I...

Embodiment 2

[0038] A kind of preparation method of aluminum oxide coating lithium ion battery cathode material of the present invention, its specific preparation process is as follows:

[0039] The commercial layered high-nickel material Ni0.75 co 0.1 mn 0.15 (OH) 2 For coating object, coat with reference to the method for embodiment 1: with 10gNi 0.75 co 0.1 mn 0.15 (OH) 2 The material was placed in 80ml of deionized water and stirred to disperse, and after 30min, press Al 2 o 3 The mass coating amount is 3wt% to calculate and prepare sodium metaaluminate solution, mix the two, place in a water bath at 70±5°C and pass CO 2 gas, after stirring for 120min to obtain Al(OH) 3 The coated precursor material is washed and filtered, dried in an oven at 80°C and then mixed with lithium for sintering. The temperature system of the sintering process is two-stage heating in an oxygen atmosphere, pre-sintering at 480°C for 300 minutes, and then heating to 780°C for sintering for 900 minutes ...

Embodiment 3

[0041] A kind of preparation method of aluminum oxide coating lithium ion battery cathode material of the present invention, its specific preparation process is as follows:

[0042] The commercial layered high-nickel material Ni 0.6 co 0.2 mn 0.2 (OH) 2 For coating object, coat with reference to the method for embodiment 1: with 10g Ni 0.6 co 0.2 mn 0.2 (OH) 2 The material was placed in 80ml of deionized water and stirred to disperse, and after 30min, press Al 2 o 3 The mass coating amount is 3wt% to calculate and prepare sodium metaaluminate solution, mix the two, place in a water bath at 70±5°C and pass CO 2 gas, after stirring for 120min to obtain Al(OH) 3 The coated precursor material is washed and filtered, dried in an oven at 80°C and then mixed with lithium for sintering. The temperature system of the sintering process is two-stage heating in an oxygen atmosphere, pre-sintering at 480°C for 300 minutes, and then heating to 780°C for sintering for 900 minutes ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com