Three-dimensional macroporous graphene, carbon nano tube and molybdenum disulfide composite material, and preparation method and application of composite material

A technology of three-dimensional macropores and carbon nanotubes, which is applied to electrical components, battery electrodes, circuits, etc., can solve the problems of poor stability and low first-time cycle efficiency, and achieve good stability, high lattice integrity, and ease of expansion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

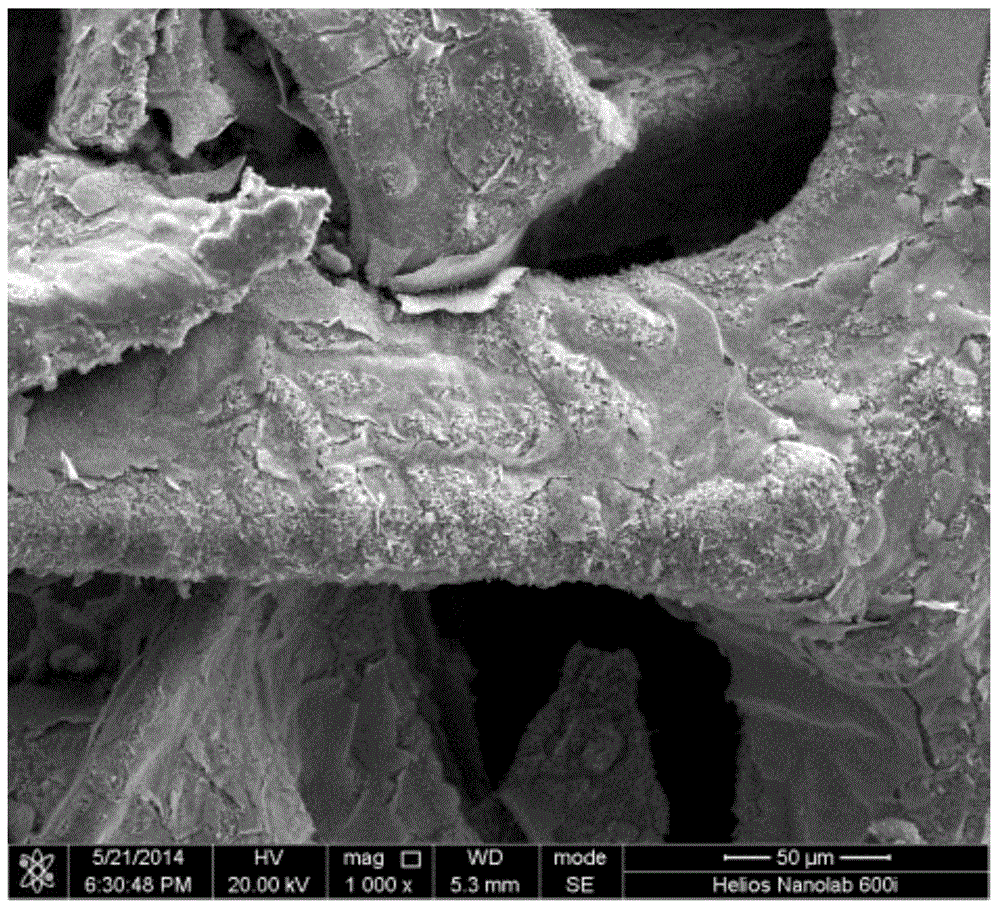

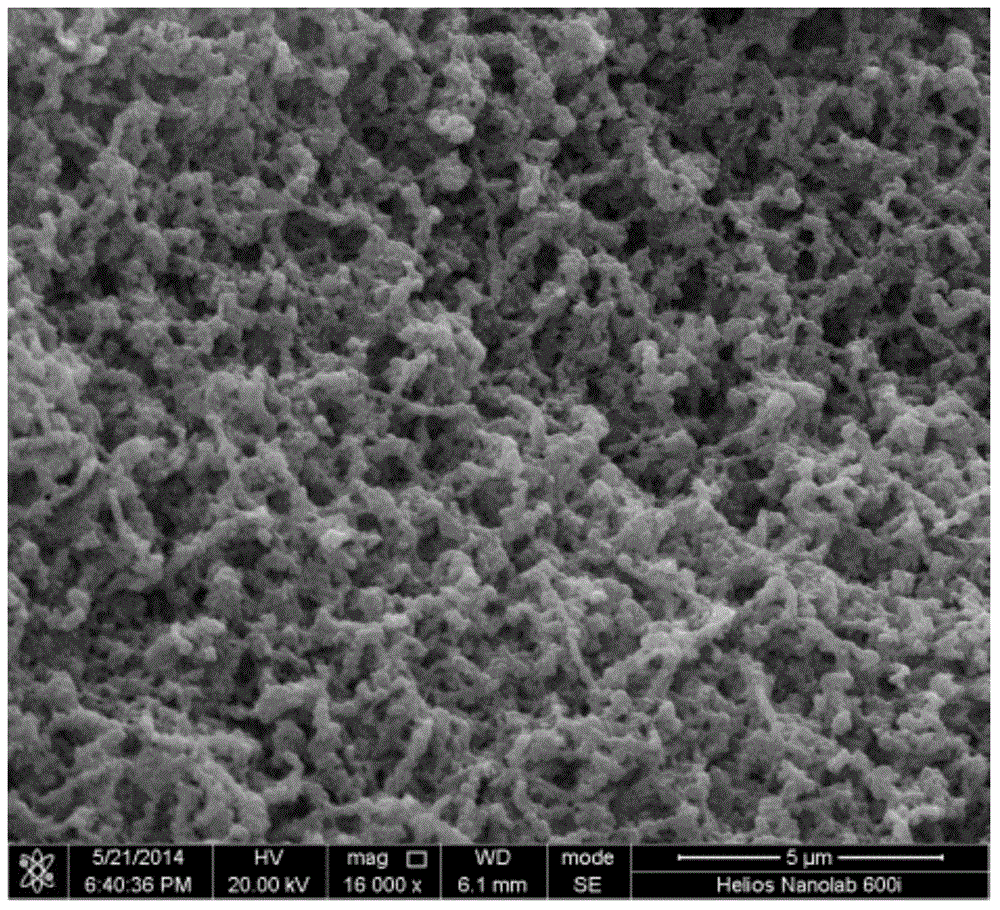

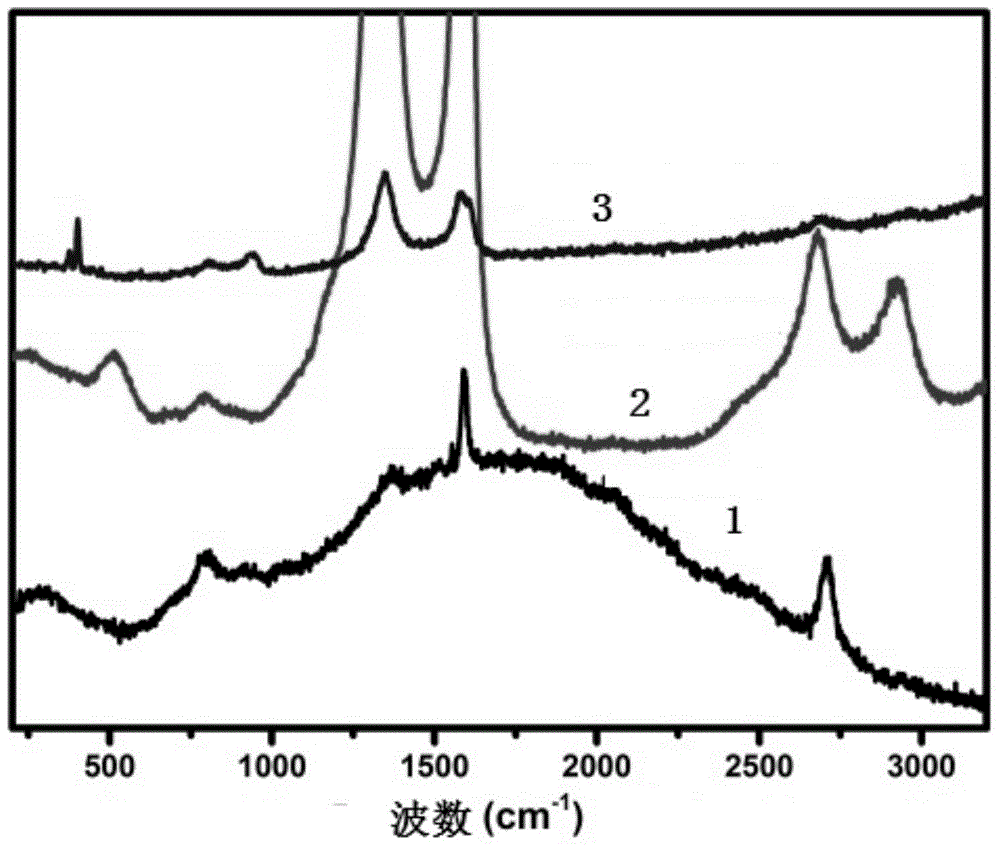

[0035] Specific embodiment 1: A three-dimensional macroporous graphene-carbon nanotube-molybdenum disulfide composite material described in this embodiment is obtained by pretreatment and chemical vapor deposition of metal foam with a pore diameter of 0.1 mm to 5 mm. Porous graphene / foamed metal composite, then place the three-dimensional macroporous graphene / foamed metal composite in an aqueous solution of nickel nitrate and cobalt chloride, dry, and chemical vapor deposition to obtain a three-dimensional macroporous graphene / carbon nanotube / Foamed metal composites, immersing the three-dimensional macroporous graphene / carbon nanotubes / foamed metal composites in the etching solution to obtain three-dimensional macroporous graphene / carbon nanotubes. Molybdenum disulfide is loaded on the nanotubes to obtain three-dimensional macroporous graphene / carbon nanotubes loaded with molybdenum disulfide, and finally the three-dimensional macroporous graphene / carbon nanotubes loaded with ...

specific Embodiment approach 2

[0040] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the metal foam with a pore size of 0.1 mm to 5 mm is pretreated and chemical vapor deposited to obtain a three-dimensional macroporous graphene / metal foam composite. It is carried out according to the following steps: the metal foam with a pore diameter of 0.1 mm to 5 mm is immersed in acetone for 3 min to 15 min, ethanol for 3 min to 15 min, and hydrochloric acid with a mass percentage of 1% to 5% for 3 min to 7 min to obtain the base material. Then place the base material in a chemical vapor deposition device, pass through carbon source gas and carrier gas, and deposit at a temperature of 850°C to 1100°C for 4min to 15min to obtain a three-dimensional macroporous graphene / foam metal composite;

[0041] The total gas flow of the carbon source gas and carrier gas is 20 sccm to 800 sccm; the carbon source gas is methane, and the gas flow of methane is 0.5 sccm to 20 sccm; the carrier gas is a mi...

specific Embodiment approach 3

[0042] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the described three-dimensional macroporous graphene / foam metal composite is placed in the aqueous solution of nickel nitrate and cobalt chloride, dried, and then Chemical vapor deposition to obtain a three-dimensional macroporous graphene / carbon nanotube / foam metal composite, specifically as follows: ① Dissolve nickel nitrate and cobalt chloride in deionized water to obtain nickel nitrate and cobalt chloride immerse the three-dimensional macroporous graphene / foam metal composite in the aqueous solution of nickel nitrate and cobalt chloride for 30min to 60min, then take it out and dry it on a hot plate at a temperature of 30°C to 50°C; ②, repeat Step 2 ① 5 to 10 times to obtain the impregnated composite material; ③, place the impregnated composite material in a chemical vapor deposition device at a temperature of 600°C to 850°C at a rate of 4.5mL / min to 5.5mL / The ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| cycle efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com