Nitrogen-doped carbon-loaded ruthenium monatomic catalyst as well as preparation method and application thereof

A nitrogen-doped carbon and catalyst technology, which is applied in the preparation of amino compounds, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of high catalyst cost, environmental pollution, poor selectivity of alicyclic amines, etc., and achieve simple process, Reduced production cost and ease of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] This example provides a nitrogen-doped carbon-supported ruthenium single-atom catalyst for the one-step hydrogenation of nitroaromatic compounds to prepare alicyclic amines. The preparation method is as follows:

[0074] (1) Put urea in a crucible, cover it, and calcinate it in a muffle furnace at 600°C for 4h, wash the obtained solid three times with deionized water and ethanol, and then dry it in a blast drying oven at 100°C 12h, obtain carbon nitride;

[0075] (2) Mix carbon nitride with polyionic liquid (number average molecular weight: 150,000) with the following structure at a mass ratio of 5:1 and then calcinate in a tube furnace at 750°C for 1 h in a nitrogen atmosphere to obtain nitrogen-doped carbon;

[0076]

[0077] (3) 0.04g RuCl 3 Dissolve in 10mL deionized water to obtain a metal ruthenium precursor solution with a concentration of 0.004g / mL; disperse 2.00g of the nitrogen-doped carbon powder obtained in step (2) in 60mL of deionized water, and ultras...

Embodiment 2

[0082] This example provides a nitrogen-doped carbon-supported ruthenium single-atom catalyst for the one-step hydrogenation of nitroaromatic compounds to prepare alicyclic amines. The preparation method is as follows:

[0083] (1) Put urea and melamine in a crucible at a mass ratio of 4:1, cover the lid, and calcinate in a muffle furnace at 550°C for 3 hours. The obtained solids are washed three times with deionized water and ethanol, and then placed in Dry in a blast drying oven at 100°C for 12 hours to obtain carbon nitride;

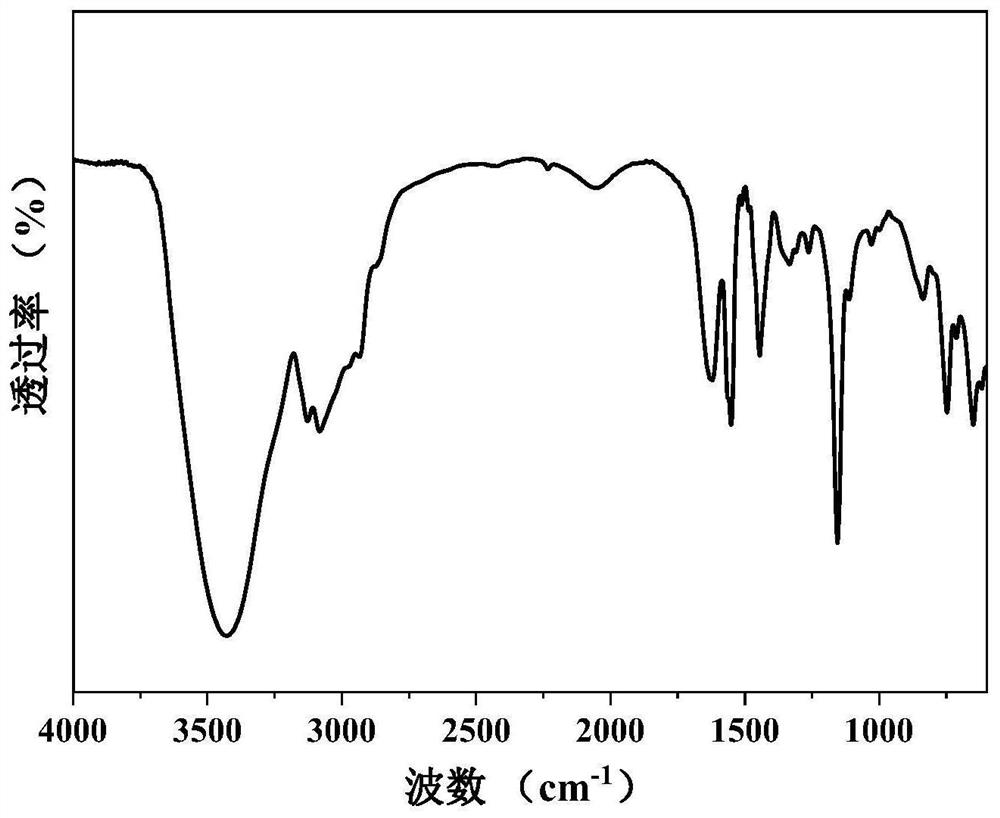

[0084] (2) After mixing carbon nitride and polyionic liquid with the following structure at a mass ratio of 3:1, they were calcined in a tube furnace at 700° C. for 1 h in a nitrogen atmosphere to obtain nitrogen-doped carbon; the infrared of the polyionic liquid Spectral graph such as figure 1 shown;

[0085]

[0086] (3) 0.05g RuCl 3 Dissolve in 5mL deionized water to obtain a metal ruthenium precursor solution with a concentration of 0.01g / mL; ...

Embodiment 3

[0091] This example provides a nitrogen-doped carbon-supported ruthenium single-atom catalyst for the one-step hydrogenation of nitroaromatic compounds to prepare alicyclic amines. The preparation method is as follows:

[0092] (1) Put melamine in a crucible, cover it, and calcinate it in a muffle furnace at 550°C for 4 hours, wash the obtained solid three times with deionized water and ethanol, and then dry it in a blast drying oven at 100°C 12h, obtain carbon nitride;

[0093] (2) Mix carbon nitride with polyionic liquid (number average molecular weight 80,000) with the following structure at a mass ratio of 8:1, and then calcine in a tube furnace at 680°C for 1.5 hours in a nitrogen atmosphere to obtain nitrogen-doped carbon;

[0094]

[0095] (3) 0.04g RuCl 3 Dissolve in 20mL deionized water to obtain a metal ruthenium precursor solution with a concentration of 0.002g / mL; disperse 3.00g of the nitrogen-doped carbon powder obtained in step (2) in 70mL of deionized water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com