Lamellar catalyst containing mesoporous titanium-silicate molecular sieves and preparation method and application of lamellar catalyst

A titanium-silicon molecular sieve and catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of improving diffusion, improving activity, and improving lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

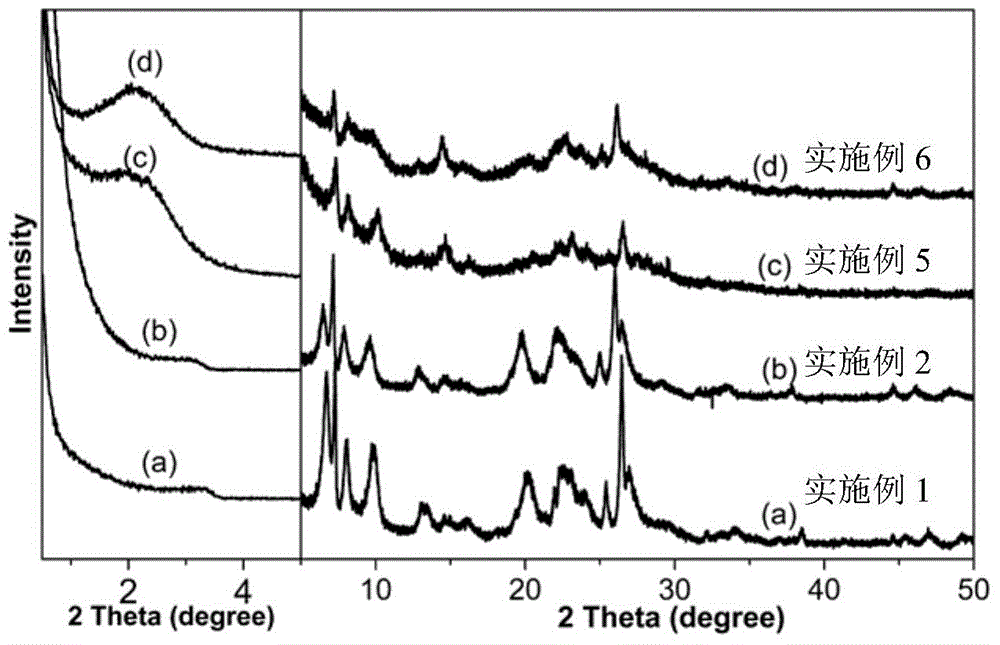

[0064] [Example 1] Preparation of molecular sieve MCM-22 precursor

[0065] The synthesis of MCM-22 precursor uses white carbon black as silicon source, sodium metaaluminate (NaAlO 2 ) is the aluminum source, and hexamethyleneimine (HMI) is the template agent. A typical synthesis method is as follows: under vigorous stirring, NaOH and NaAlO 2 Dissolve in distilled water, slowly add white carbon black, and finally add HMI. Stirring was continued for 2h to obtain a white gel. The molar composition of the mixture is n(Si):n(Al):n(HMI):n(NaOH):n(H 2 (0) = 1:0.07:0.5:0.1:30. The gel was transferred to a 50 mL stainless steel reaction kettle lined with polytetrafluoroethylene, and crystallized at a temperature of 150 °C for 5 days. The stirring speed is 60r / min. After the crystallization was completed, cool down to room temperature, filter the reaction liquid with suction, and rinse repeatedly with distilled water until the washing liquid is neutral. The resulting white filte...

Embodiment 2

[0066] [Example 2] Preparation of molecular sieve ERB-1 precursor

[0067] The synthesis of ERB-1 precursor uses white carbon black as silicon source, boric acid (H 3 BO 3 ) is the boron source, and piperidine (PI) is the template agent. A typical synthesis method is as follows: under vigorous stirring, dissolve NaOH and boric acid into distilled water, slowly add white carbon black, and finally add PI. Stirring was continued for 2h to obtain a white gel. The molar composition of the mixture is n(Si):n(B):n(PI):n(NaOH):n(H 2 (0)=1:2:1.4:0.12:25. The gel was transferred to a 50 mL stainless steel reaction kettle lined with polytetrafluoroethylene, and crystallized at a temperature of 150 °C for 5 days. The stirring speed is 60r / min. After the crystallization was completed, cool down to room temperature, filter the reaction liquid with suction, and rinse repeatedly with distilled water until the washing liquid is neutral. The resulting white filter cake was dried at 100°C...

Embodiment 3

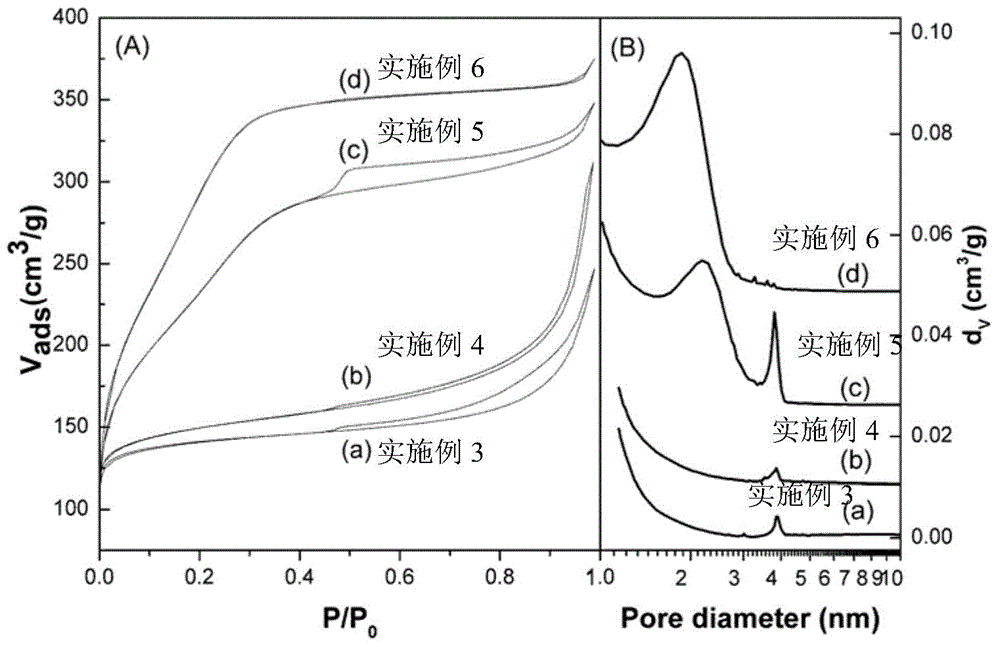

[0068] [embodiment 3] preparation MCM-22 molecular sieve

[0069] The MCM-22 (P) that [embodiment 1] obtains is put into tubular quartz furnace, under nitrogen atmosphere (SV=1240h -1 ) to 600°C at a rate of 3°C / min. After 30 minutes, switch to air with the same space velocity, and continue calcining for 12 hours to obtain MCM-22 molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com