Single-crystal appearance layered nickel lithium manganate positive electrode material and preparation method thereof

A technology of lithium nickel manganese oxide and positive electrode materials, which is applied in the field of layered lithium nickel manganese oxide positive electrode materials and its preparation, can solve problems such as lack of coordination, nickel-lithium mixed row, and influence on the electrochemical performance of positive electrode materials, and achieve electrochemical performance. Excellent performance, improved volume energy density, and improved structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

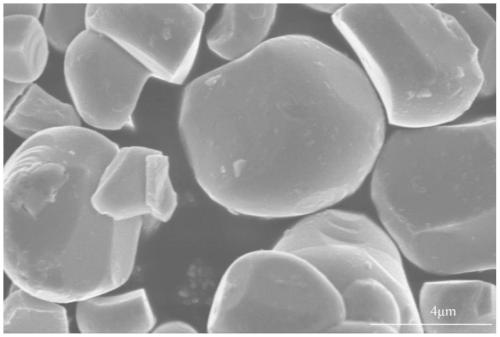

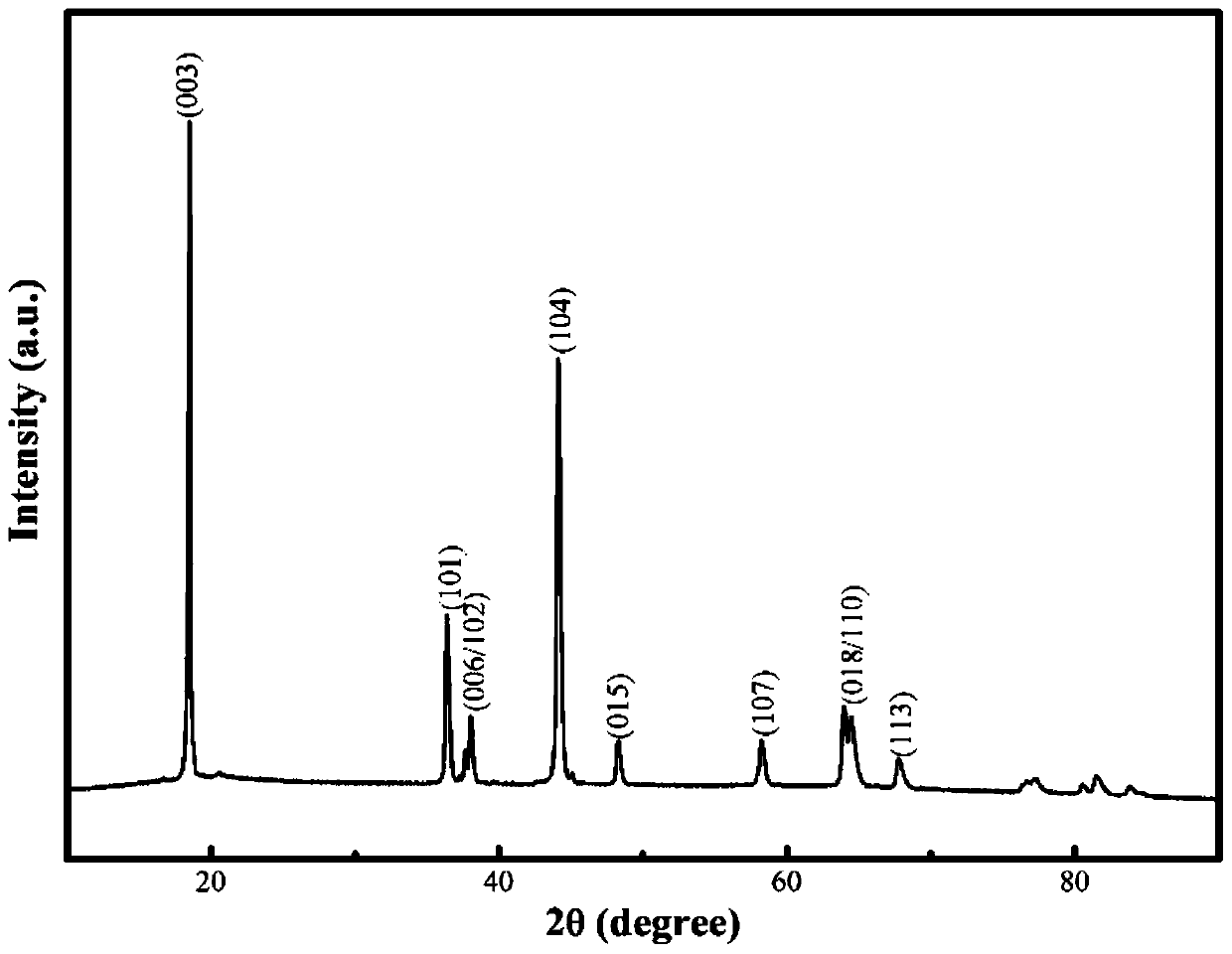

[0049] Nickel nitrate and manganese nitrate were dissolved in deionized water at a molar ratio of 1:1 to prepare a salt solution with a metal ion concentration of 0.6mol / L. Ammonia water is used as a complexing agent, and the three components are introduced into the reactor with equal volumes by a peristaltic pump. The reaction temperature is controlled at 50±0.5°C, the pH value is 9±0.2, and the stirring speed is 1200r / min. After reacting for 20 h, the obtained precipitate was washed with deionized water for 3 times, and then dried at 120 ° C for 18 h under a nitrogen protective atmosphere to obtain the nickel manganese double hydroxide precursor Ni 0.5 mn 0.5 (OH) 2 , its D 50 is 4.4μm, BET is 87.4m 2 / g.

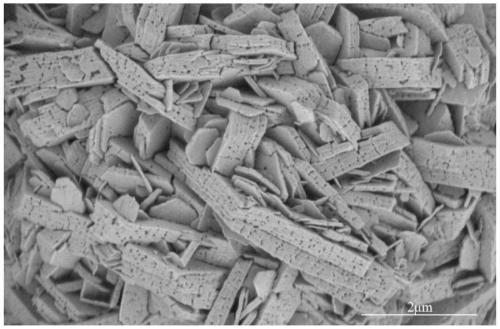

[0050] The above precursor was pre-calcined at 500°C for 4 hours, and the product obtained was the precursor of nickel manganese oxide. The oxide precursor obtained by pre-calcination maintains the sheet-like structure of the double hydroxide primary particle, and at...

Embodiment 2

[0054] Nickel nitrate and manganese sulfate were dissolved in deionized water at a molar ratio of 1:1 to prepare a salt solution with a metal ion concentration of 0.5 mol / L. At the same time, sodium hydroxide with the same volume and concentration was prepared as a precipitating agent. Ammonia water is used as a complexing agent, and the three components are introduced into the reactor with equal volumes by a peristaltic pump. The reaction temperature is controlled at 80±0.5°C, the pH value is 10.5±0.2, and the stirring speed is 700r / min. After reacting for 13 hours, the precipitate obtained was washed with deionized water for 3 times, and then dried at 115°C for 28 hours under a nitrogen protective atmosphere to obtain the nickel-manganese double hydroxide precursor Ni 0.5 mn 0.5 (OH) 2 , its D 50 3.9μm, BET 98.1m 2 / g.

[0055] The above precursor was pre-calcined at 550° C. for 3 hours, and the product obtained was the precursor of nickel manganese oxide.

[0056] The ...

Embodiment 3

[0059] Nickel acetate and manganese acetate were dissolved in deionized water at a molar ratio of 1:1 to prepare a salt solution with a metal ion concentration of 0.9mol / L. At the same time, the same volume and concentration of sodium carbonate was prepared as a precipitant, and 0.8mol / L ammonia water As a complexing agent, the three components are introduced into the reactor with equal volumes by a peristaltic pump, the reaction temperature is controlled at 65±0.5°C, the pH value is 12.0±0.2, and the stirring speed is 1000r / min. After reacting for 9 hours, the obtained precipitate was washed with deionized water for 3 times, and then dried at 130°C for 18 hours under a nitrogen protective atmosphere to obtain the nickel manganese carbonate precursor Ni 0.5 mn 0.5 CO 3 , its D 50 is 3.6μm, BET is 115.8m 2 / g.

[0060] The above precursor was pre-calcined at 480° C. for 6 hours, and the product obtained was the precursor of nickel manganese oxide.

[0061] The above-mentio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com