Die casting system for preparing aluminum alloy die castings and die casting process

A die-casting process and die-casting technology, applied in the field of die-casting systems and die-casting processes, can solve the problems of surface blistering, strength reduction, electrical conductivity reduction, etc., and achieve the effects of reducing surface blistering, improving qualification rate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

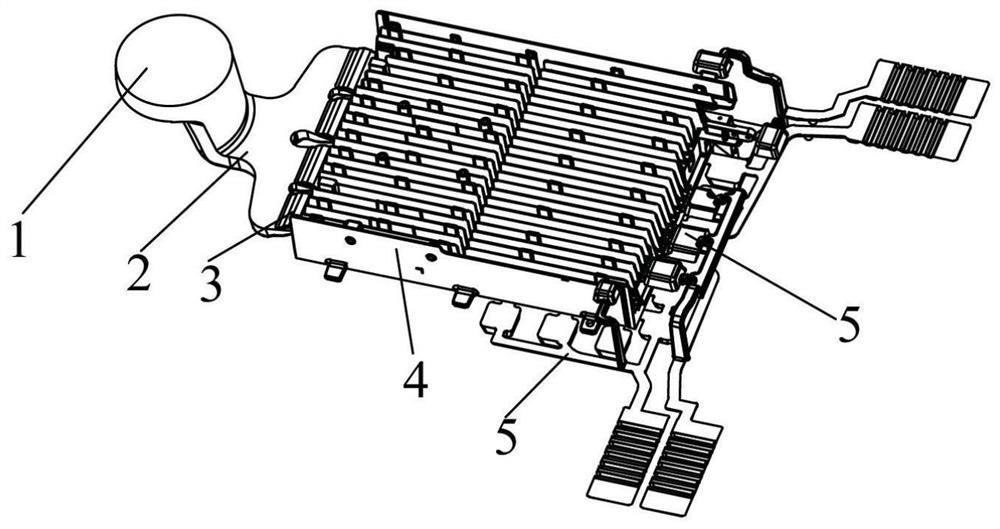

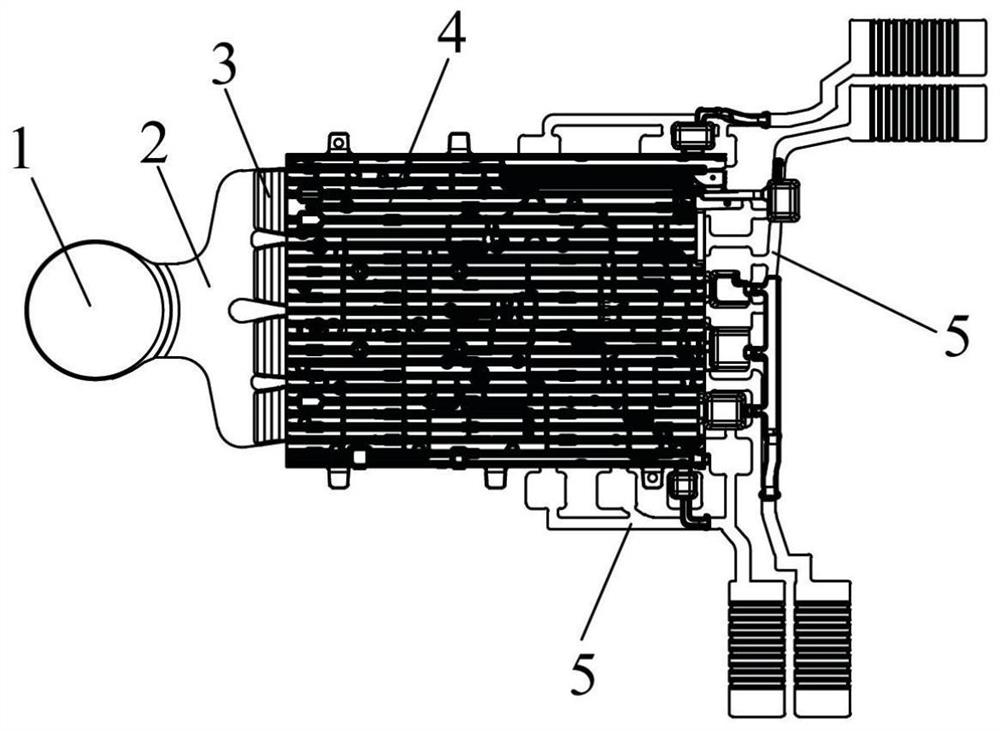

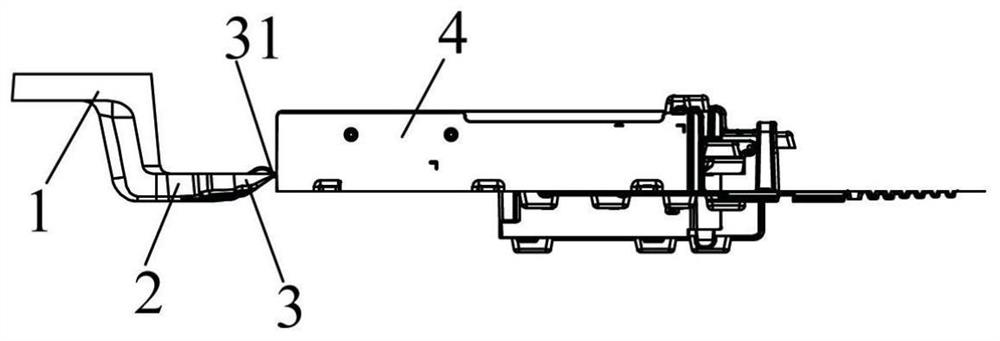

Image

Examples

Embodiment 1

[0048] Adopt die-casting system of the present invention (jet flow angle is 30 °) to prepare aluminum alloy die-casting, concrete die-casting process comprises the following steps:

[0049] 1) First melt the alloy raw materials (by mass fraction, 10% silicon, 13.5% iron, less than 1% copper, less than 0.55% manganese, less than 0.15% zinc and 80%-88% aluminum) and then use refining agent to melt Alloy raw materials are refined and cleaned, then adding a refiner, and then applying ultrasound to disperse the refiner in the melt, and at the same time remove the gas from the alloy solution, let it stand, and keep it warm for later use;

[0050] 2) Turn on the die-casting system, preheat the die-casting system to the specified temperature (150-200°C) and keep it warm for 10-15 minutes to make the temperature of each part of the die-casting system consistent;

[0051] 3) Raise the temperature of the preheated die-casting system to the working temperature (180-210°C), inject the allo...

Embodiment 2

[0054] The difference with embodiment 1 is:

[0055] The jet angle is 33°.

[0056] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0058] The difference with embodiment 1 is:

[0059] The jet angle is 35°.

[0060] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com