Lithium battery anode material and preparation method and application thereof

A positive electrode material and lithium battery technology, applied in battery electrodes, secondary battery manufacturing, batteries, etc., can solve problems affecting battery cycle performance and safety performance, hindering the movement of lithium ions on the surface, low discharge voltage and volume density, etc., to achieve Improve cycle performance and safety performance, reduce the degree of cation mixing, and improve the effect of capacity fading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

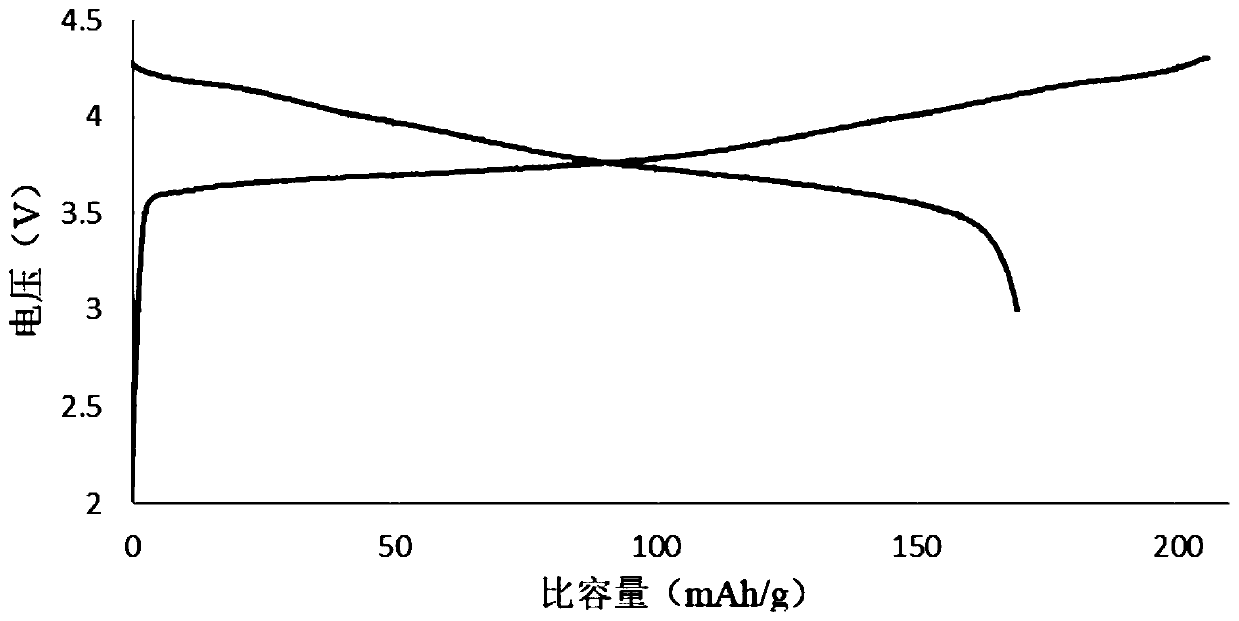

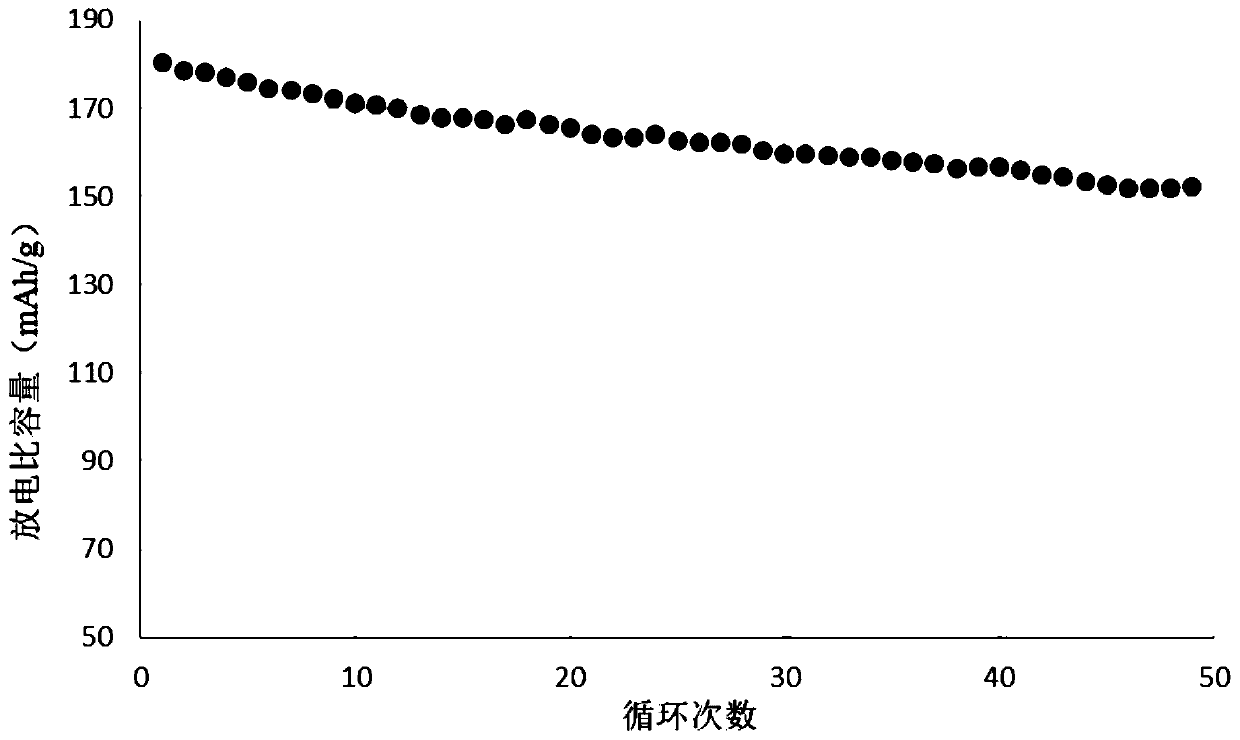

Embodiment 1

[0045] The positive electrode material for lithium batteries has a lithium metal composite oxide with a layered structure and a boron coating layer formed on the surface of the lithium metal composite oxide, wherein the chemical formula of the lithium metal composite oxide is Li 1.02 m e M1 0.015 o 2 , where M e The chemical formula is Ni 0.8 co 0.1 mn 0.085 , M1 is Zr; the doping amount of the doping element is 3wt‰ of the positive electrode material, the content of the boron coating layer is 1.5wt‰ of the positive electrode material, and the a-axis lattice parameter of the lithium metal composite oxide is not low At The c-axis lattice parameter is not less than

[0046] The method for preparing the positive electrode material for the lithium battery is as follows: (1) using the doping element M1 to dope the metal oxide containing Li and Ni to obtain a lithium metal composite oxide; (2) adding H 3 BO 3 The fine powder is mixed with the lithium metal composite oxid...

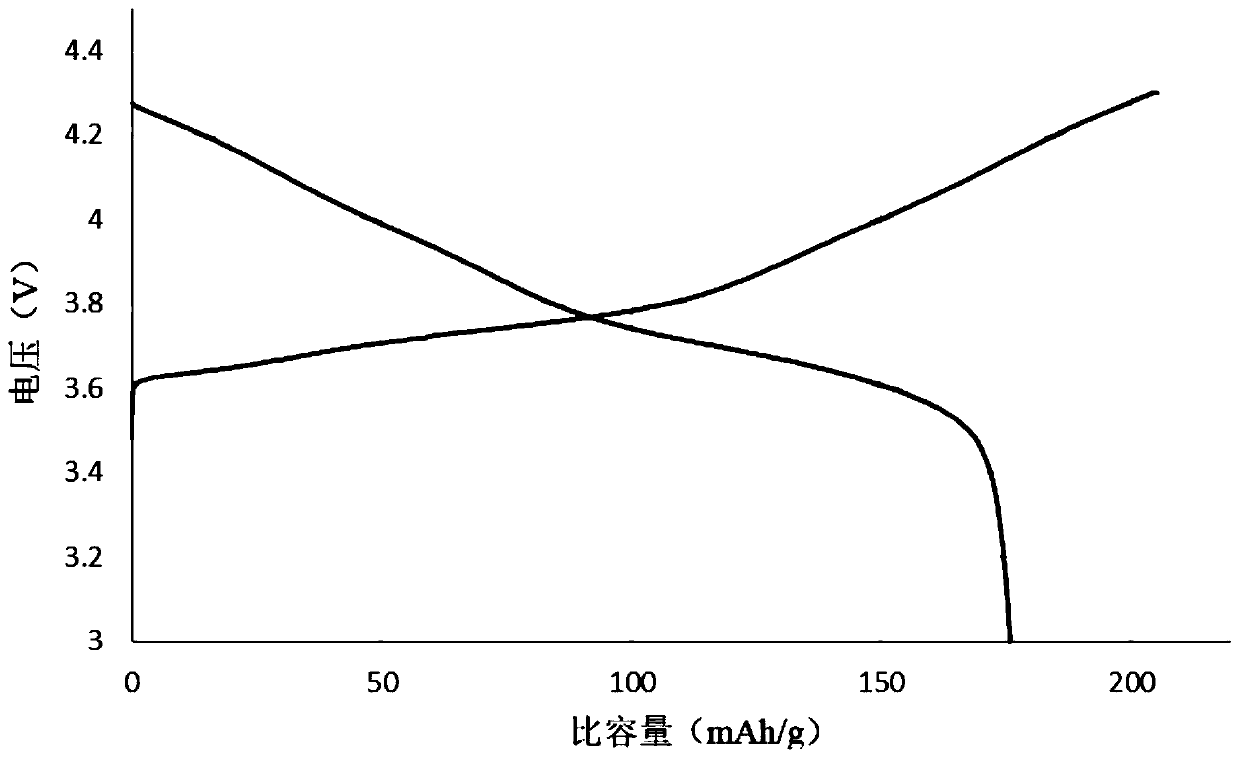

Embodiment 2

[0048] The positive electrode material for lithium batteries has a lithium metal composite oxide with a layered structure and a boron coating layer formed on the surface of the lithium metal composite oxide, wherein the chemical formula of the lithium metal composite oxide is Li 1.02 m e M1 0.015 o 2 , where M e The chemical formula is Ni 0.8 co 0.1 mn 0.085 , M1 is Zr; the doping amount of the doping element is 3wt‰ of the positive electrode material, the content of the boron coating layer is 1.5wt‰ of the positive electrode material, and the a-axis lattice parameter of the lithium metal composite oxide is not low At The c-axis lattice parameter is not less than

[0049] The method for preparing the positive electrode material for the lithium battery is as follows: (1) using the doping element M1 to dope the metal oxide containing Li and Ni to obtain a lithium metal composite oxide; (2) adding H 3 BO 3 Dissolved in ultrapure water, and then added lithium metal com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com