Sludge dewatering method

A sludge dewatering and sludge technology, applied in sewage/sludge fertilizer, dewatering/drying/concentrating sludge treatment, application, etc., can solve the problems of reducing sludge moisture content, poor dewatering performance, etc. The effect of pollution, good hardness and easy subsequent use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

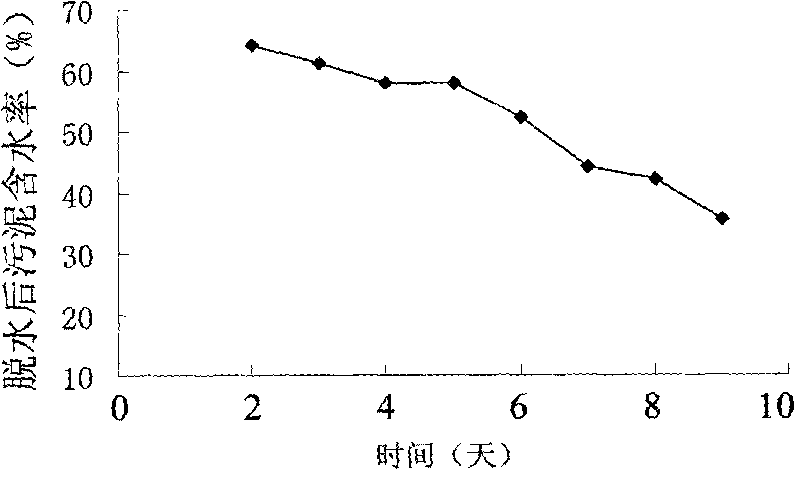

Image

Examples

Embodiment Construction

[0026] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

[0027]1. Conditioning: The concentrated sludge (with a moisture content of about 96%) is sent to the sludge storage tank in the dewatering machine room by gravity or sludge pumping for sludge conditioning test. The test process is mainly divided into comprehensive test stage and orthogonal test Stage: First use the beaker experiment to test several coagulants according to the same dosage, observe the situation of the flocs, and screen out the best agents, and then use the gravity filtration test to verify the effects of these agents. Judging the turbidity of the filtrate and evaluating the volume of the filtrate to evaluate the conditioning effect of the agent, the ideal conditioner should make the filtrate clear, with a large amount of filtrate and low turbidity. Therefore, in the gravity filtration test, the filtrate turbidity and the volume of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com