Complete plate tube-sheet type photovoltaic hot-water module

A tube-sheet type and whole-plate type technology, which is applied in the field of laser welding whole-plate tube-sheet type photovoltaic water heating modules, can solve the limitation of battery series and parallel connection, restrict the success rate of photovoltaic cells, and the performance of solar photovoltaic water heating technology cannot be guaranteed and other issues, to achieve the effect of improving heat collection efficiency and solar energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

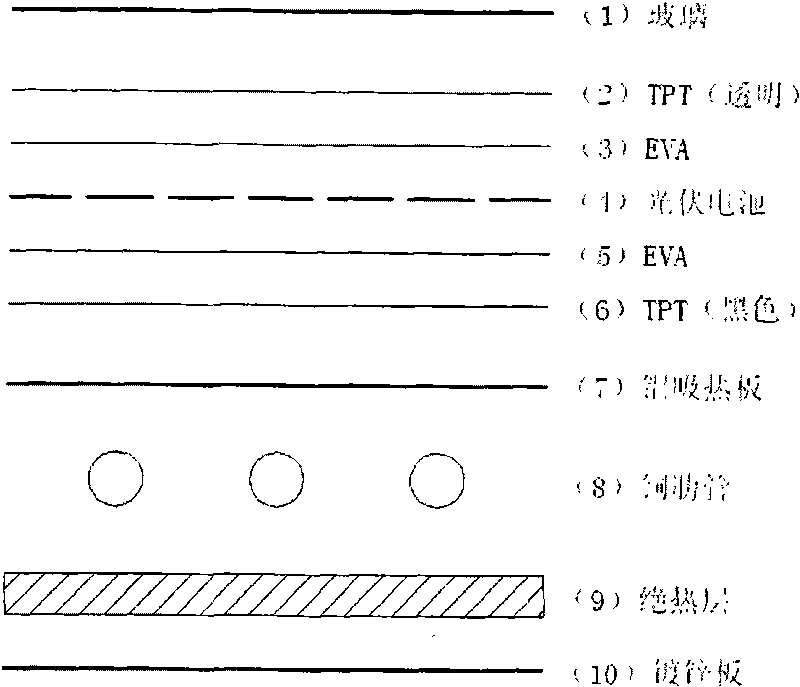

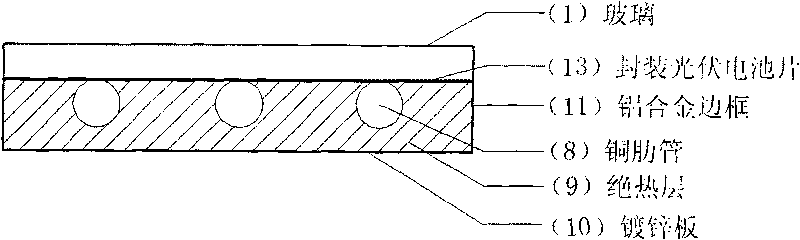

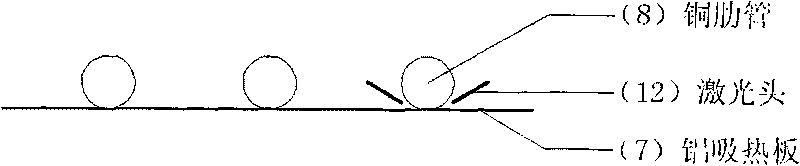

[0016] like figure 1 As shown, the whole-plate tube-sheet photovoltaic hot water module of the present invention includes: glass 1 , encapsulated photovoltaic cells 13 , copper-finned tubes 8 , heat insulating layer 9 and galvanized plate 10 . Encapsulating photovoltaic cells 13 consists of photovoltaic cells 4, ethylene-vinyl acetate EVA 3 and 5 wrapped up and down the photovoltaic cells 4, transparent composite fluoroplastic film TPT 2 on the upper layer of EVA, black TPT 6 on the lower layer of EVA, and aluminum under the black TPT 6. Heat absorbing plate 7 constitutes. On the back of the aluminum heat absorbing plate 7, the copper rib tube 8 is laser spot welded by the laser head 12, and then the heat insulating layer 9 and the galvanized plate 10 are covered under the packaged photovoltaic cells 13, and the glass plate 1 is used above the packaged photovoltaic cells 13 For covering, there is an air gap between the top of the encapsulated photovoltaic cells 13 and the gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com