Epoxy resin composition for fiber-reinforced composite material

An epoxy resin and composite material technology, applied in the field of epoxy resin composition for fiber reinforced composite materials, can solve the problems of increased resin viscosity, high reactivity, insufficient toughness, etc. High stability and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

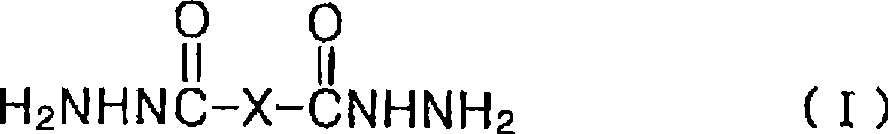

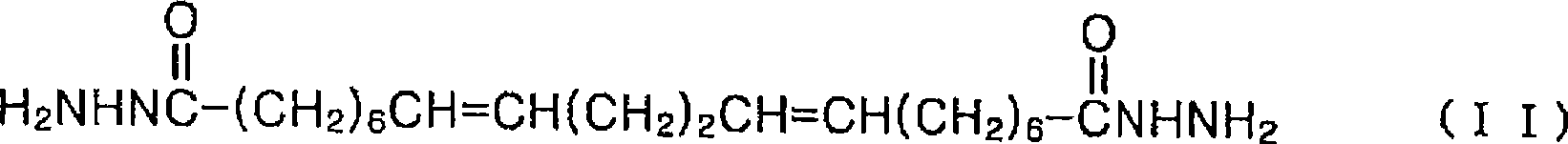

Method used

Image

Examples

Embodiment 1~6 and comparative example 1~4

[0062] As epoxy resin (A), amine curing agent (B), organic acid dihydrazide compound (C), and optional component dicyandiamide (D), thermosetting resin (E), thermoplastic resin (F) are shown in the table An epoxy resin composition was prepared using the following substances in the compounding ratio described in 1 and 2. First, using a planetary mixer set at 125° C., all of the epoxy resin (A) and thermoplastic resin (F) were stirred and mixed for 75 minutes until a uniform resin solution was obtained. Then, the temperature of this planetary mixer is set at 70°C, and when the resin temperature becomes uniform, add amine curing agent (B), organic acid dihydrazide compound (C), dicyandiamide ( D) and all of the thermosetting resin (E) particles were stirred and mixed to prepare an epoxy resin composition.

[0063] ·Epoxy resin (A)

[0064] Resin A-1: N,N,O-triglycidyl-p-aminophenol (MY-0510 manufactured by Handman Adbanst Materials Co., Ltd.)

[0065] Resin A-2: bisphenol F ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com