Method for synthesizing fatty acid ester by ester exchange reaction

A technology for synthesizing fatty acid esters and transesterification, applied in renewable energy chemical industry and green fields, can solve the problems of complex process, high energy consumption, waste liquid discharge, etc., and achieve good selectivity and stability, mild reaction conditions, High catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

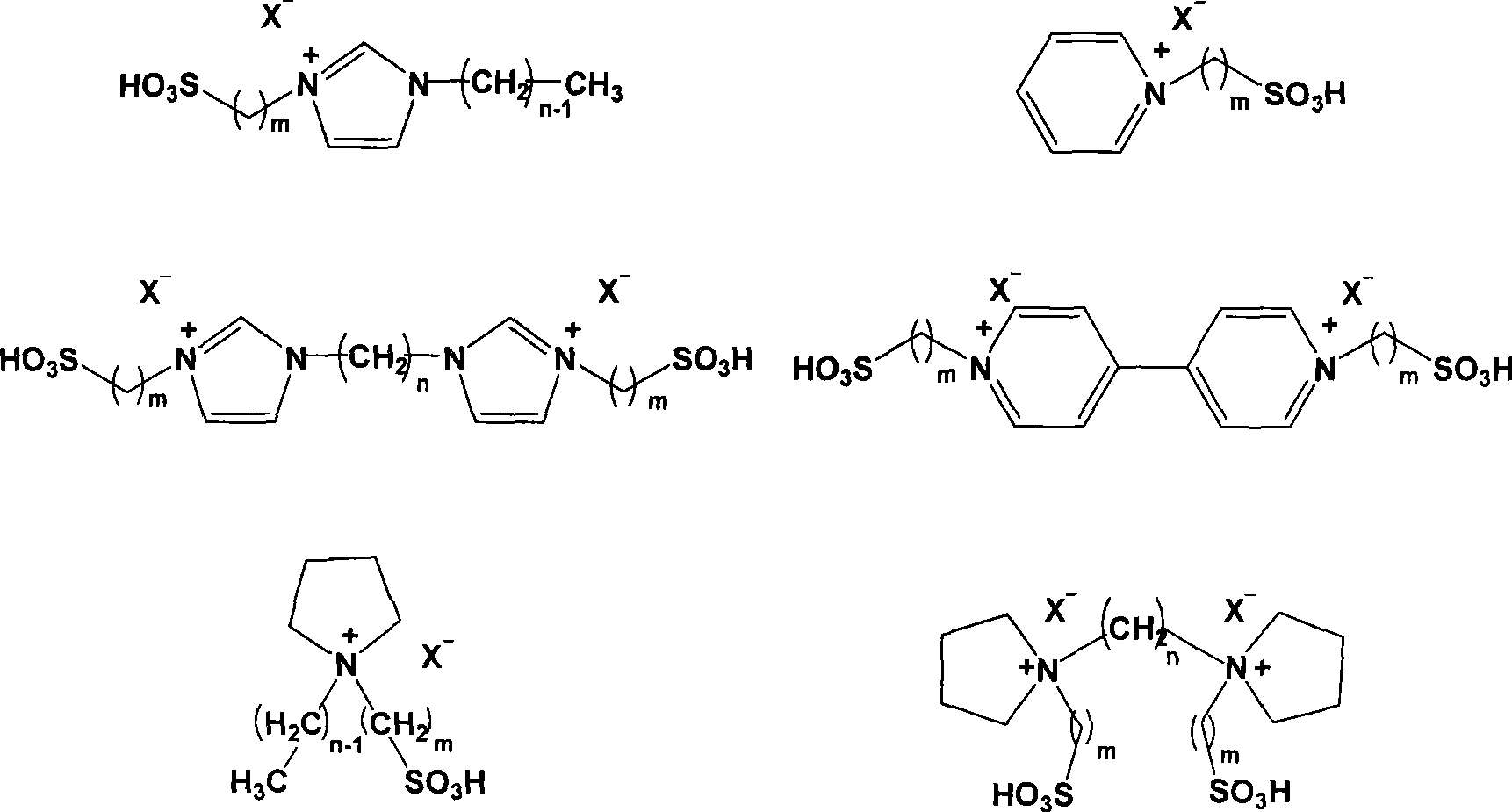

Method used

Image

Examples

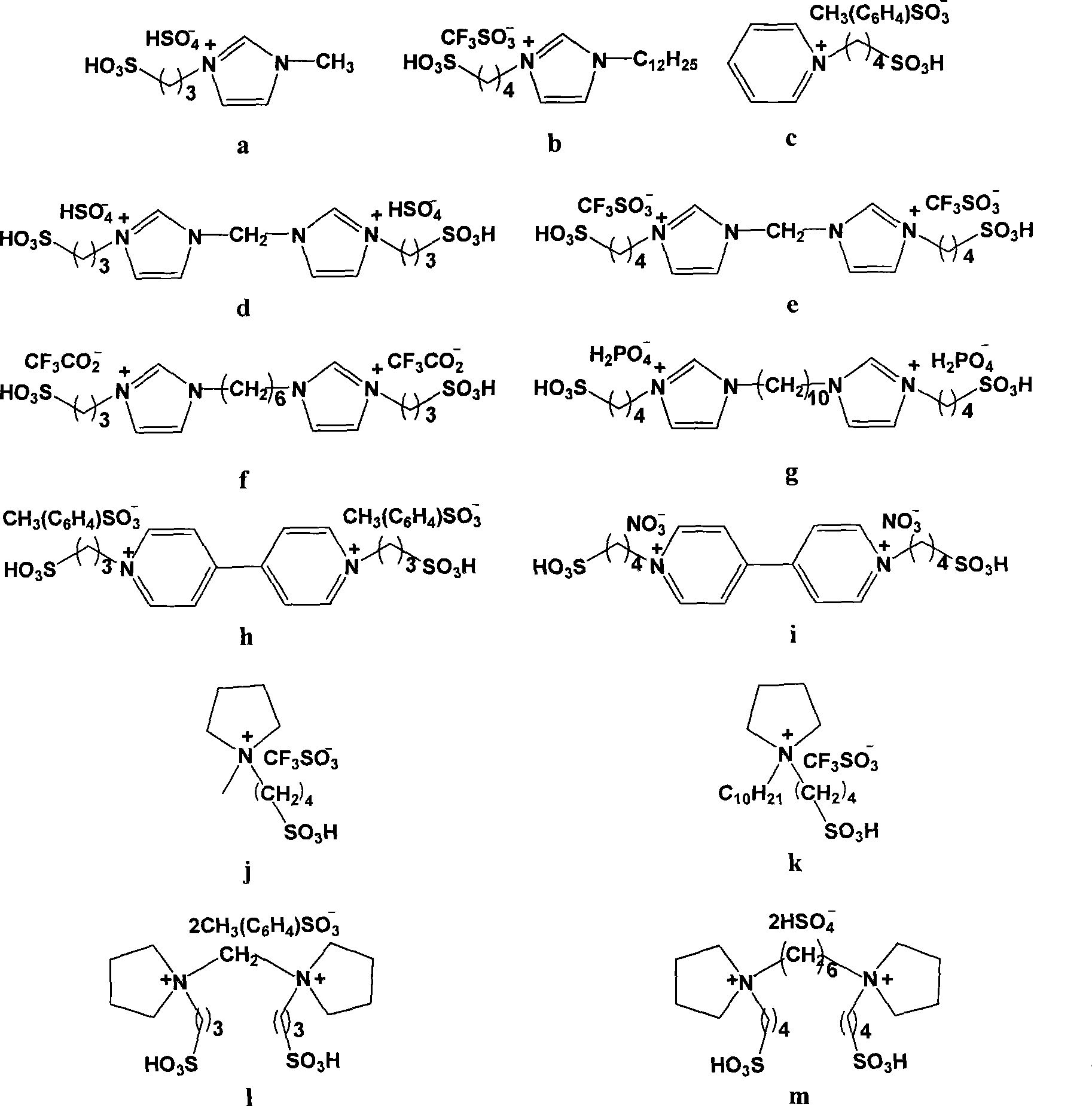

Embodiment 1

[0031] In a 250ml three-necked flask, add 100g of refined rapeseed oil, 19.92g of methanol, and 0.5% of catalyst a in oil weight according to the alcohol-to-oil molar ratio of 6:1. Heated to 65 ° C full reflux 2h. After the reaction was completed, the mixture was allowed to stand for separation, and the crude fatty acid methyl ester was collected. After washing and drying with water, it was detected by gas chromatography, and the content of the obtained fatty acid methyl ester was 95.1%.

[0032] The crude product is subjected to continuous vacuum distillation at 220-250°C to obtain refined fatty acid methyl ester.

Embodiment 2

[0034]In a 250ml three-necked flask, add 100g of peanut oil, 9.96g of methanol, and catalyst b whose weight is 5% of the oil weight according to the alcohol-to-oil molar ratio of 3:1. Heated to 65 ° C full reflux 2h. After the reaction was completed, the mixture was allowed to stand for separation, and the crude fatty acid methyl ester was collected. After washing and drying with water, it was detected by gas chromatography, and the content of the obtained fatty acid methyl ester was 94.0%.

[0035] The crude product is subjected to continuous vacuum distillation at 220-250°C to obtain refined fatty acid methyl ester.

Embodiment 3

[0037] In a 250ml three-necked flask, add 100g of soybean oil, 33.2g of methanol, and a catalyst c whose weight is 1% of the oil weight according to the molar ratio of alcohol to oil of 10:1. Heated to 80 ° C full reflux 6h. After the reaction was completed, the mixture was allowed to stand for separation, and the crude fatty acid methyl ester was collected. After washing and drying with water, it was detected by gas chromatography. The content of the obtained fatty acid methyl ester was 91.8%.

[0038] The crude product is subjected to continuous vacuum distillation at 220-250°C to obtain refined fatty acid methyl ester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com