Electrolyte additive, non-aqueous electrolyte and lithium-ion battery thereof

An electrolyte additive and non-aqueous electrolyte technology, which is applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of battery positive electrode material corrosion, poor compatibility, and insufficient energy density, and achieve high-temperature cycle performance improvement and high-temperature storage Effects of performance improvement and low-temperature cycle performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In a nitrogen-filled glove box (O 2 2 (02 2 (0<1ppm), slowly add 20g of lithium hexafluorophosphate into the mixed solution, and mix well to make a non-aqueous electrolyte.

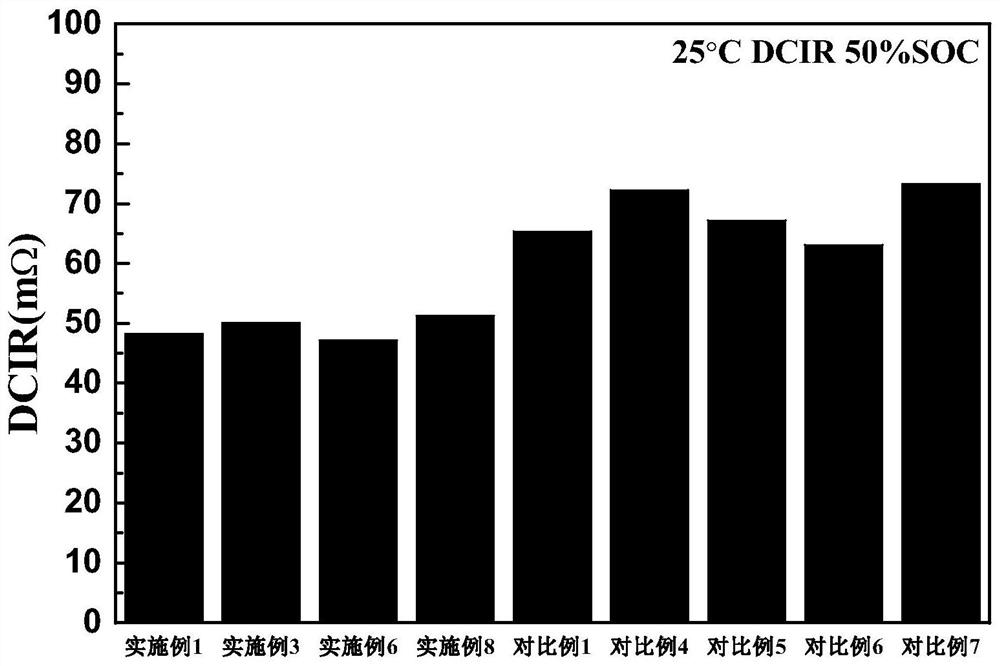

[0040] The non-aqueous electrolyte formulas of Examples 2-17 and Comparative Examples 1-7 are shown in Table 2, and the steps of preparing the non-aqueous electrolyte are the same as in Example 1.

[0041] Table 2 Non-aqueous electrolyte formula

[0042]

[0043]

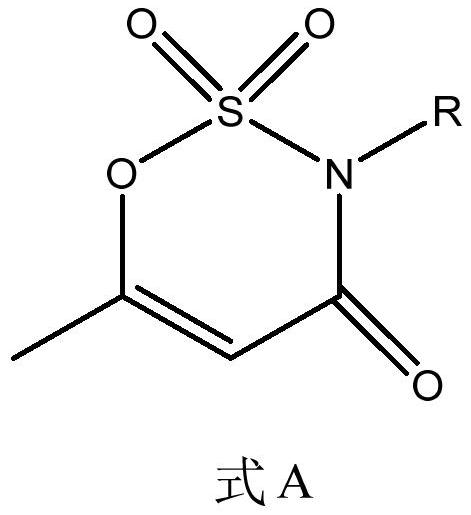

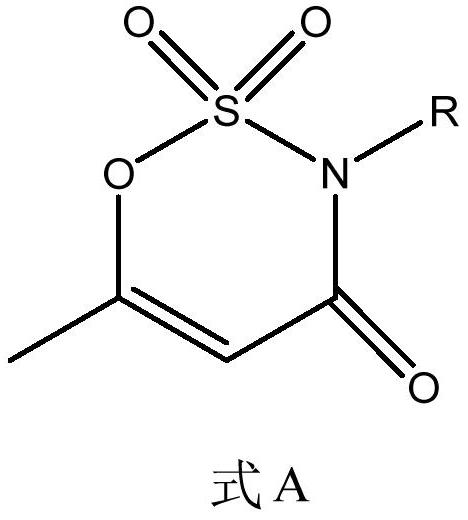

[0044] Wherein TFSI is trifluoromethanesulfonamide, and its structural formula is as follows:

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com