Dipping adhesive for flexible industrial canvas and preparation method of dipping adhesive

A dipping liquid and industrial technology, which is applied to the dipping liquid of flexible industrial canvas and its preparation field, can solve the problems of the conveyor belt being easily worn, affecting the transmission effect, and lacking flexibility, etc. performance, excellent flexural resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

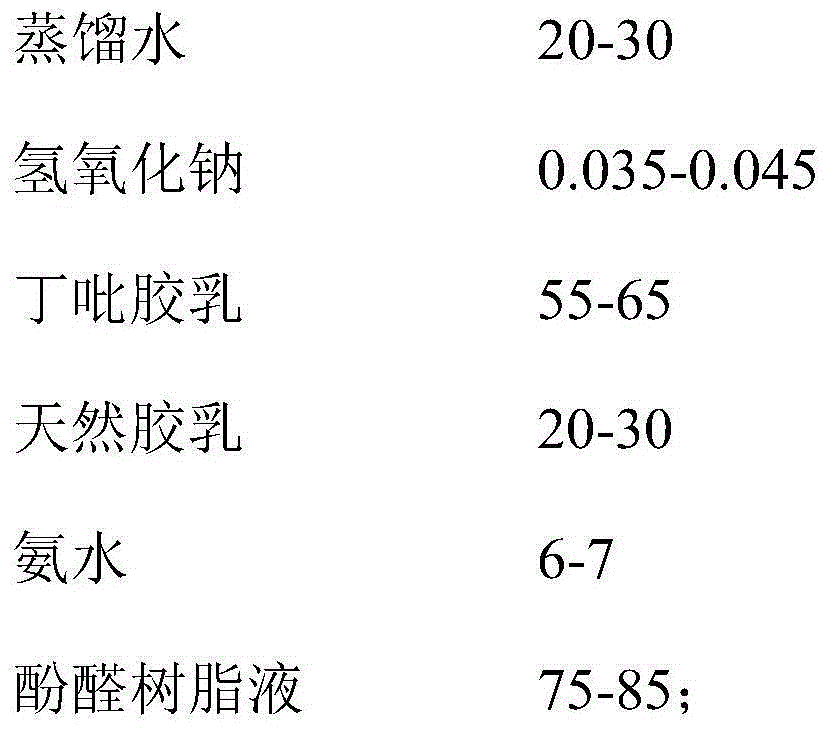

[0027] A dipping solution for flexible industrial canvas, comprising the following raw materials in parts by weight:

[0028]

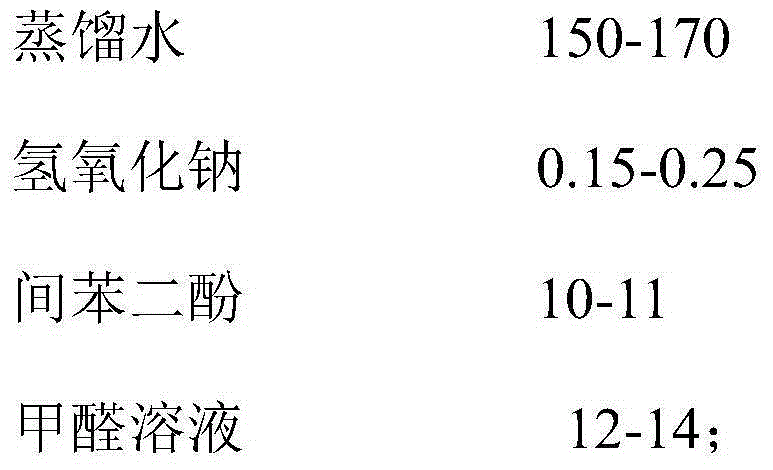

[0029] The formula of described phenolic resin liquid comprises the raw material of following weight portion:

[0030]

[0031] The purity of the sodium hydroxide is ≧96%, the mass percent concentration of formaldehyde is 37%, the mass percent concentration of butylpyridine latex is 40%, the mass percent concentration of natural rubber latex is 30%~40%, the mass percent concentration of ammonia water The percent concentration is 19%.

[0032] A preparation method for a dipping solution of flexible industrial canvas, comprising the following steps:

[0033] ⑴ According to the formula of dipping solution, add distilled water into the reaction vessel, then add sodium hydroxide, mix and stir until dissolved;

[0034] (2) Then add the butylpyridine latex in the formula amount, and stir evenly;

[0035] (3) Add the ammonia water of formula quantity...

Embodiment 2

[0042] A dipping solution for flexible industrial canvas, comprising the following raw materials in parts by weight:

[0043]

[0044] The formula of described phenolic resin liquid comprises the raw material of following weight portion:

[0045]

[0046] The purity of the sodium hydroxide is ≧96%, the mass percent concentration of formaldehyde is 37%, the mass percent concentration of butylpyridine latex is 40%, the mass percent concentration of natural rubber latex is 30%~40%, the mass percent concentration of ammonia water The percent concentration is 19%.

[0047] A preparation method for a dipping solution of flexible industrial canvas, comprising the following steps:

[0048] ⑴ According to the formula of dipping solution, add distilled water into the reaction vessel, then add sodium hydroxide, mix and stir until dissolved;

[0049] (2) Then add the butylpyridine latex in the formula amount, and stir evenly;

[0050] (3) Then add the amount of ammonia water in t...

Embodiment 3

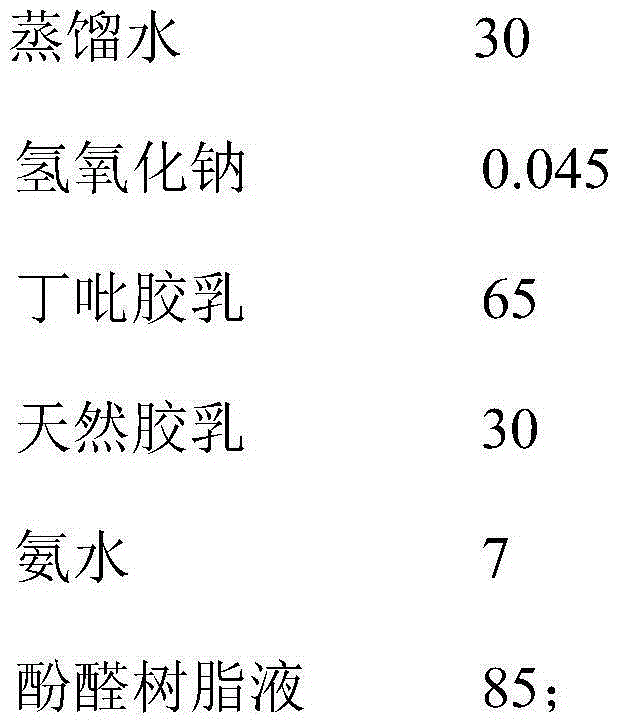

[0057] A kind of dipping liquid of flexible industrial canvas, its formula comprises the raw material of following weight part:

[0058]

[0059]

[0060] The formula of described phenolic resin liquid comprises the raw material of following weight portion:

[0061]

[0062] The purity of the sodium hydroxide is ≧96%, the mass percent concentration of formaldehyde is 37%, the mass percent concentration of butylpyridine latex is 40%, the mass percent concentration of natural rubber latex is 30%~40%, the mass percent concentration of ammonia water The percent concentration is 19%.

[0063] A preparation method for a dipping solution of flexible industrial canvas, comprising the following steps:

[0064] ⑴ According to the formula of dipping solution, add distilled water into the reaction vessel, then add sodium hydroxide, mix and stir until dissolved;

[0065] (2) Then add the butylpyridine latex in the formula amount, and stir evenly;

[0066] (3) Add the amount of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com