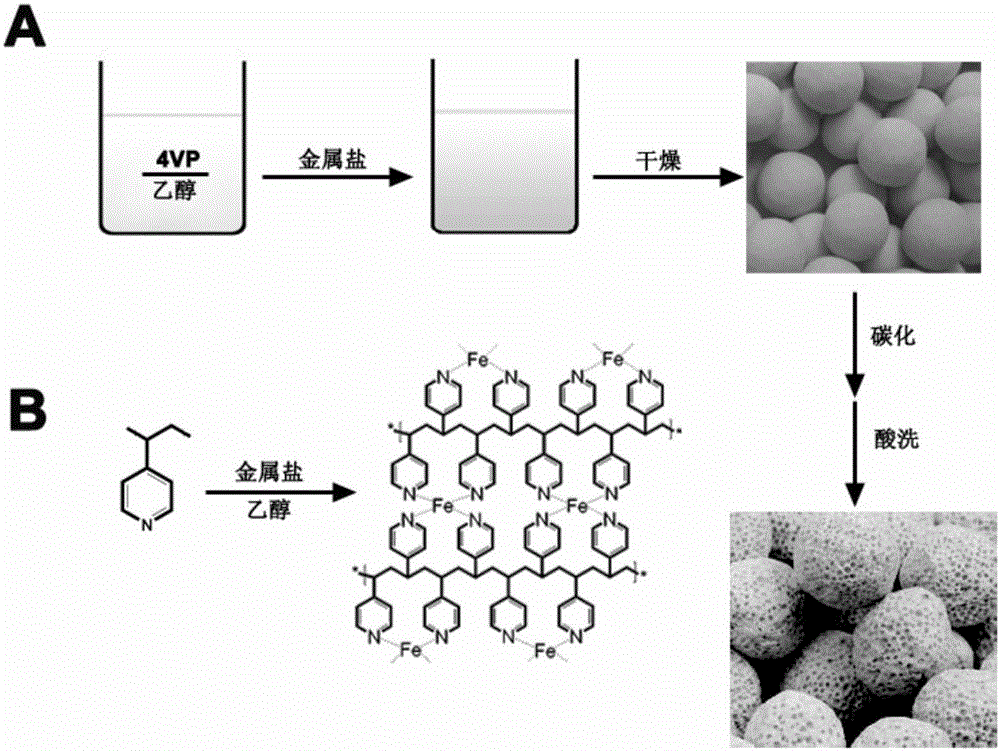

Preparation method of metal-nitrogen-doped porous carbon microspheres

A nitrogen-doped porous carbon and nitrogen-doped carbon technology is applied in the preparation/purification of carbon, which can solve the problems of easy falling off, easy decomposition, poor stability, etc., and achieves large specific surface area, simple steps, and wide selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

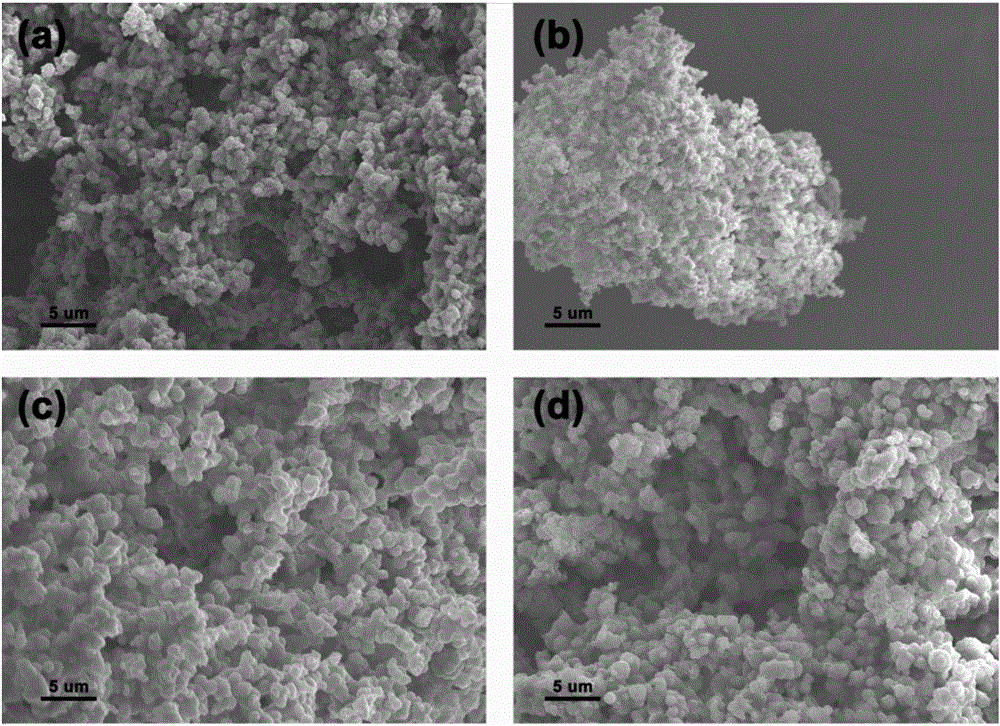

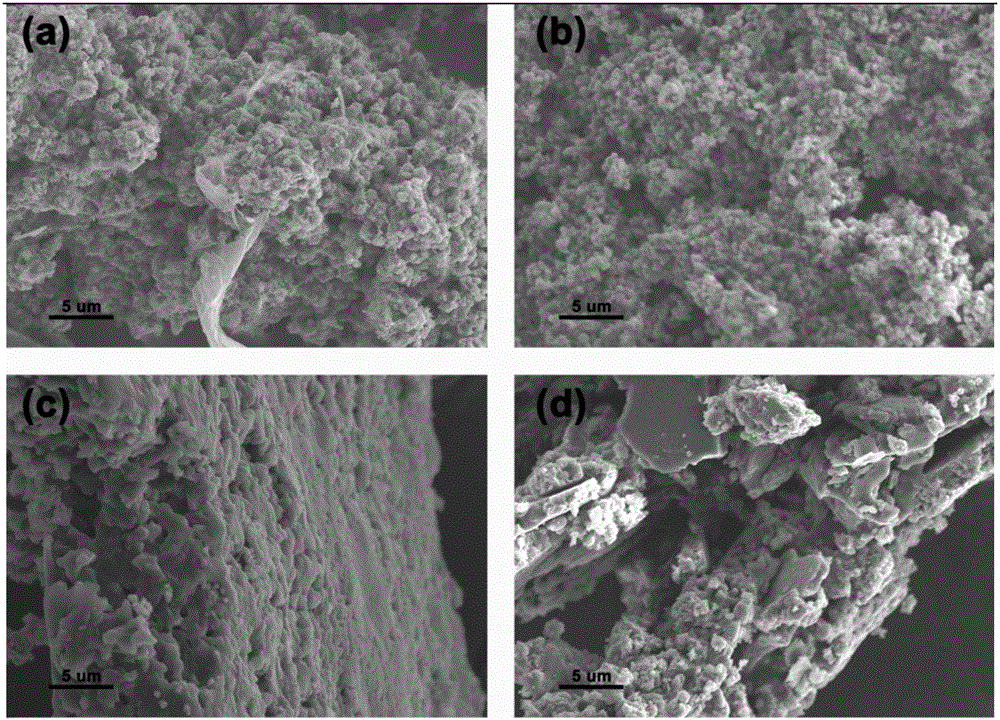

Embodiment 1

[0033] (1) Preparation of 4VP / absolute ethanol solution: at room temperature, take 1.07ml of 4VP monomer and add it to 250ml of absolute ethanol, and magnetically stir to dissolve 4VP to obtain a 4VP / absolute ethanol solution with a concentration of 0.04mol / L for later use .

[0034] (2) Preparation of FeCl 3 / absolute ethanol solution: take 1.62g FeCl 3 Dissolve in 250ml absolute ethanol, magnetically stir to make FeCl 3 Dissolve FeCl with a concentration of 0.04mol / L 3 / absolute ethanol solution for use.

[0035] (3) Fe 3+ - Preparation of organic microspheres: under magnetic stirring conditions at room temperature, take 25ml FeCl 3 / absolute ethanol solution was added to 100ml 4VP / absolute ethanol solution, molar ratio Fe 3+ : 4VP=0.25; react for 12 hours, form a stable complex precipitation, then centrifuge, dry at 60°C for 12 hours to get Fe 3+ -Organic microspheres (Fe 3+ -4VP-0.25°C).

[0036] (4) Carbonization: the Fe 3+ -4VP-0.25 is placed in a quartz bo...

Embodiment 2

[0042] (1) Preparation of 4VP / absolute ethanol solution: at room temperature, take 1.07ml of 4VP monomer and add it to 250ml of absolute ethanol, and magnetically stir to dissolve 4VP to obtain a 4VP / absolute ethanol solution with a concentration of 0.04mol / L for later use .

[0043] (2) Preparation of CuCl 2 / absolute ethanol solution: take 1.34g CuCl 2 Dissolve in 250ml absolute ethanol, magnetically stir to make CuCl 2 Dissolve CuCl with a concentration of 0.04mol / L 2 / absolute ethanol solution for use.

[0044] (3)Cu 2+ - Preparation of organic microspheres: under magnetic stirring conditions at room temperature, take 25ml CuCl 2 / absolute ethanol solution was added to 100ml 4VP / absolute ethanol solution, molar ratio Cu 2+ : 4VP=0.25; after 6 hours of reaction, a stable complex precipitate is formed, and then centrifuged, and vacuum dried at 60°C for 12 hours to obtain Cu 2+ -Organic microspheres (Cu 2+ -4VP-0.25).

[0045] (4) Carbonization: Cu 2+ -4VP-0.25 ...

Embodiment 3

[0049] (1) Preparation of 4VP / absolute ethanol solution: at room temperature, take 1.07ml of 4VP monomer and add it to 250ml of absolute ethanol, and magnetically stir to dissolve 4VP to obtain a 4VP / absolute ethanol solution with a concentration of 0.04mol / L for later use .

[0050] (2) Preparation of MgCl 2 / absolute ethanol solution: take 0.95g MgCl 2 Dissolve in 250ml of absolute ethanol, stir magnetically to make MgCl 2 Dissolved to obtain MgCl with a concentration of 0.04mol / L 2 / absolute ethanol solution for use.

[0051] (3)Mg 2+ - Preparation of organic microspheres: under the condition of magnetic stirring at room temperature, take 50ml MpCl 2 / dehydrated ethanol solution is added to 100ml 4VP / dehydrated ethanol solution, molar ratio Mg 2+ : 4VP=0.5; react for 24 hours, form a stable complex precipitation, and then centrifuge, vacuum dry at 60°C for 12 hours to get Mg 2+ -Organic microspheres (Mg 2+ -4VP-0.5).

[0052] (4) Carbonization: the Mg 2+ -4VP-0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com