Preparation method of epoxidized natural rubber masterbatch with highly dispersed nano-silicon dioxide/carbon black

A technology of nano-silica and natural rubber, which is applied in the field of preparation of nano-silica and carbon black highly dispersed in epoxidized natural rubber masterbatch, which can solve the problem of poor wear resistance, low surface wettability, and inability to achieve Green tire requirements and other issues, to achieve the effect of simple process and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

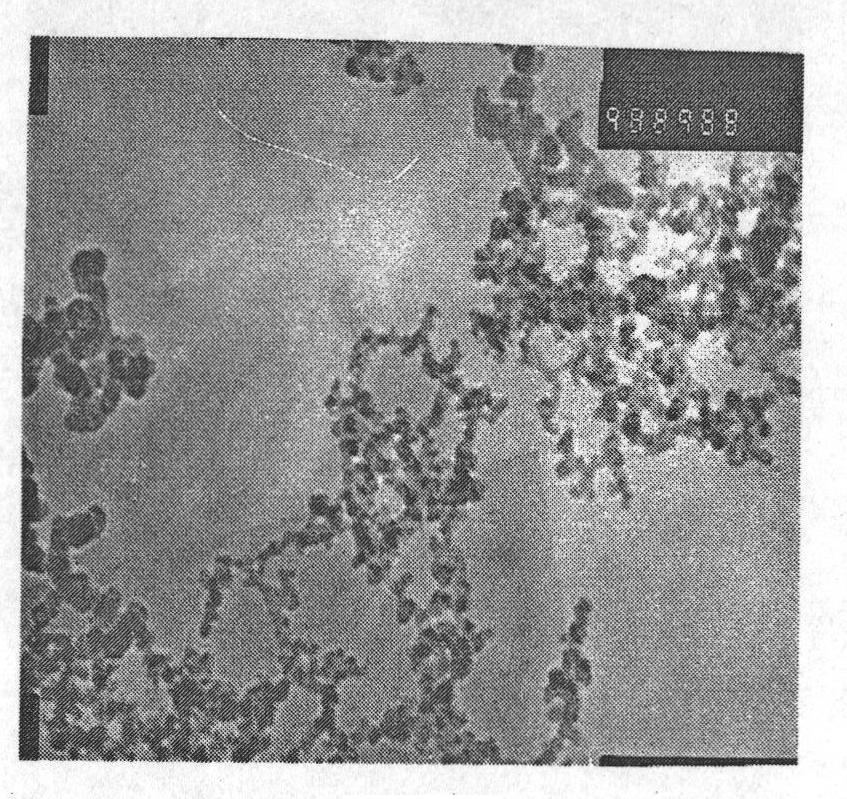

Image

Examples

Embodiment 1

[0030] a. Nano-silica modification: Measure 20 parts of Si69, add 72 mL of absolute ethanol and 8 mL of deionized water, and adjust the pH to 8-9 with 0.01 part of triethylamine at the same time, add to the weighed 5 Parts of gas-phase method nano-silica, stirred and reacted for 24 hours, then centrifuged, washed, and freeze-dried to obtain modified nano-silica, which is ready for use.

[0031] b. Modification of carbon black: Weigh 5 parts of N330, add 100 mL of deionized water, ultrasonically disperse, add 10 parts of oxidant ammonium persulfate at the same time, stir for 36 hours, centrifuge, wash, and freeze-dry to obtain oxidation modification carbon black, spare.

[0032] c. Weigh 5 parts of the modified nano-silica obtained in (a) and the modified carbon black obtained in 5 parts of (b), add them into 100 mL of deionized water respectively, disperse them ultrasonically for 5 minutes, and add them to 100 parts of epoxy resins with an epoxy degree of 25%. , in epoxidized...

Embodiment 2

[0037] a. Nano-silica modification: Measure 20 parts of KH560, add 72 mL of absolute ethanol and 8 mL of deionized water, and at the same time adjust the pH to 8-9 with 0.01 part of triethylamine, and add it to the weighed 5 Parts of nano-silica by precipitation method, stirred and reacted for 24 hours, centrifuged, washed, and freeze-dried to obtain modified nano-silica, which was set aside.

[0038] b. Modification of carbon black: Weigh 5 parts of N220, add 100 mL of deionized water, ultrasonically disperse, and add 10 parts of oxidant hydrogen peroxide at the same time, stir and react for 36 hours, centrifuge, wash, and freeze-dry to obtain oxidation modification carbon black, spare.

[0039] c. Weigh 5 parts of the modified nano-silica obtained in (a) and 5 parts of the modified carbon black obtained in (b), add them into 100mL deionized water respectively, disperse them ultrasonically for 5min, and add them to 100 parts of epoxy degree 40% , in epoxidized natural rubber...

Embodiment 3

[0044] a. Nano-silica modification: Measure 20 parts of A151, add 72 mL of absolute ethanol and 8 mL of deionized water, and at the same time adjust the pH to 8-9 with 0.01 part of triethylamine. After hydrolysis for 1 hour, add to the weighed 5 Parts of gas-phase nano-silica, stirred and reacted for 24 hours, centrifuged, washed, and freeze-dried to obtain modified nano-silica, which was set aside.

[0045] b. Modification of carbon black: Weigh 5 parts of N375, add 100 mL of deionized water, ultrasonically disperse, add 10 parts of ammonium persulfate at the same time, centrifuge, wash and freeze-dry after stirring for 36 hours to obtain oxidatively modified Carbon black, spare.

[0046] c. Weigh 5 parts of the modified nano-silica obtained in (a) and 5 parts of the modified carbon black obtained in (b), add them into 100mL of deionized water respectively, disperse by ultrasonic for 5min, and add to 100 parts of epoxy degree 50% , in epoxidized natural rubber latex with a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| 100% modulus stress | aaaaa | aaaaa |

| 300% modulus stress | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com